Hole Pattern

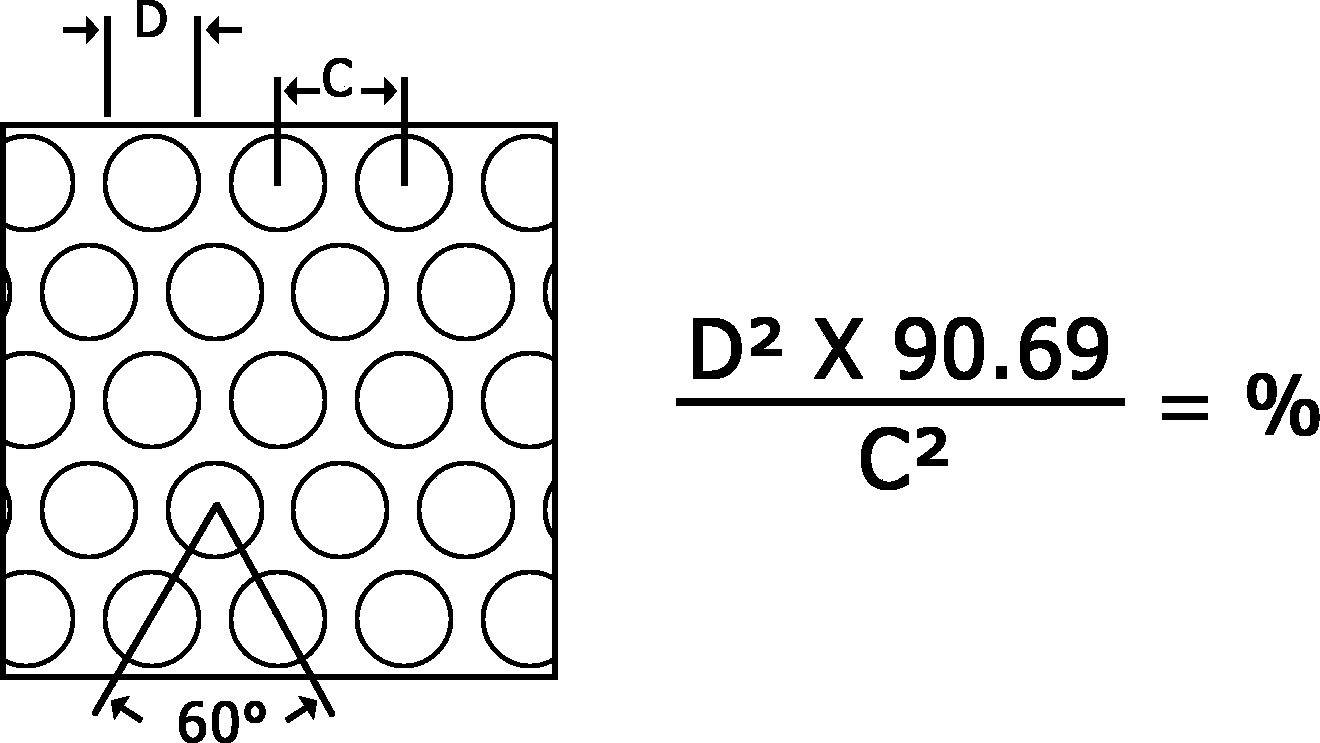

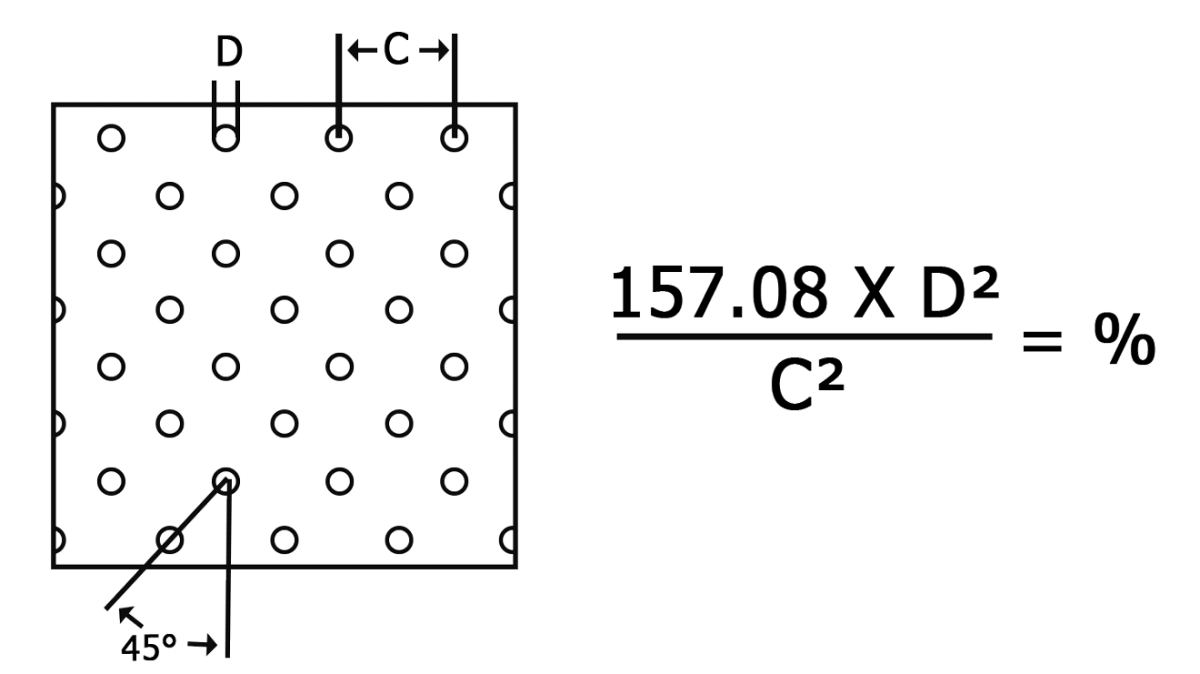

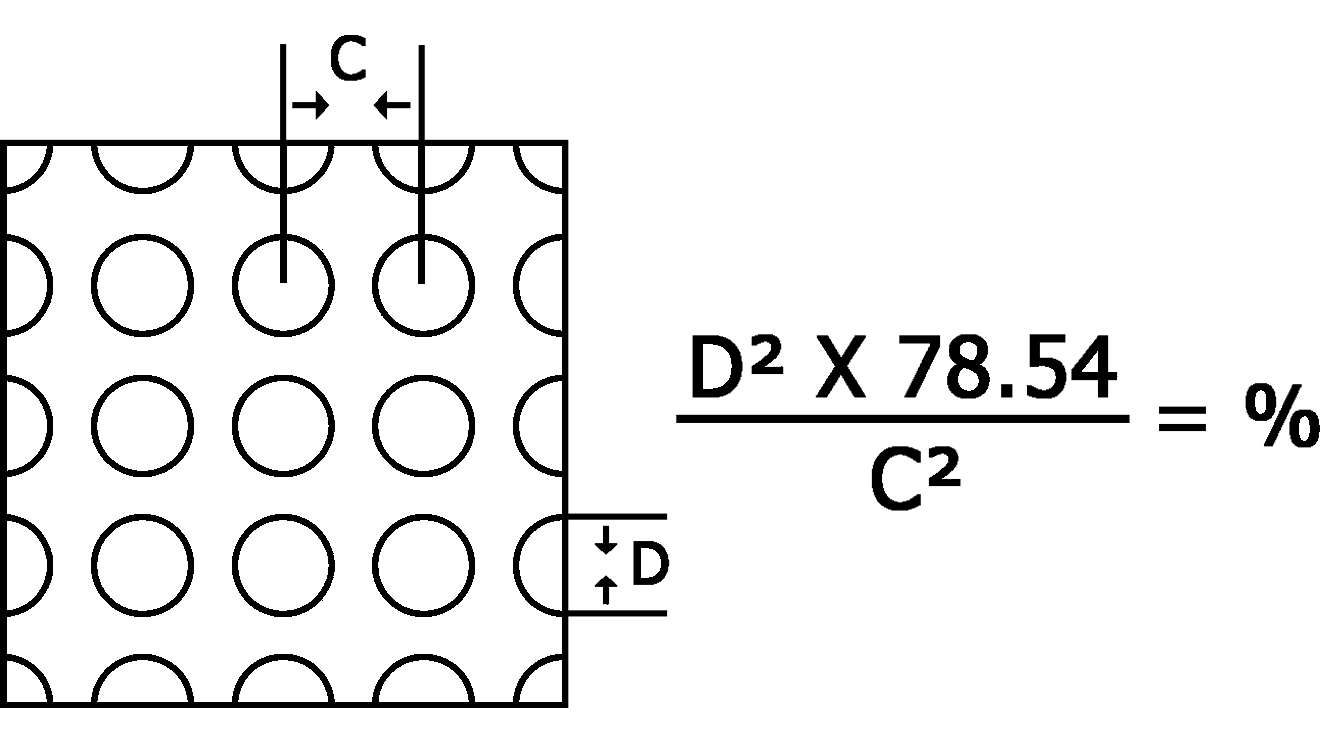

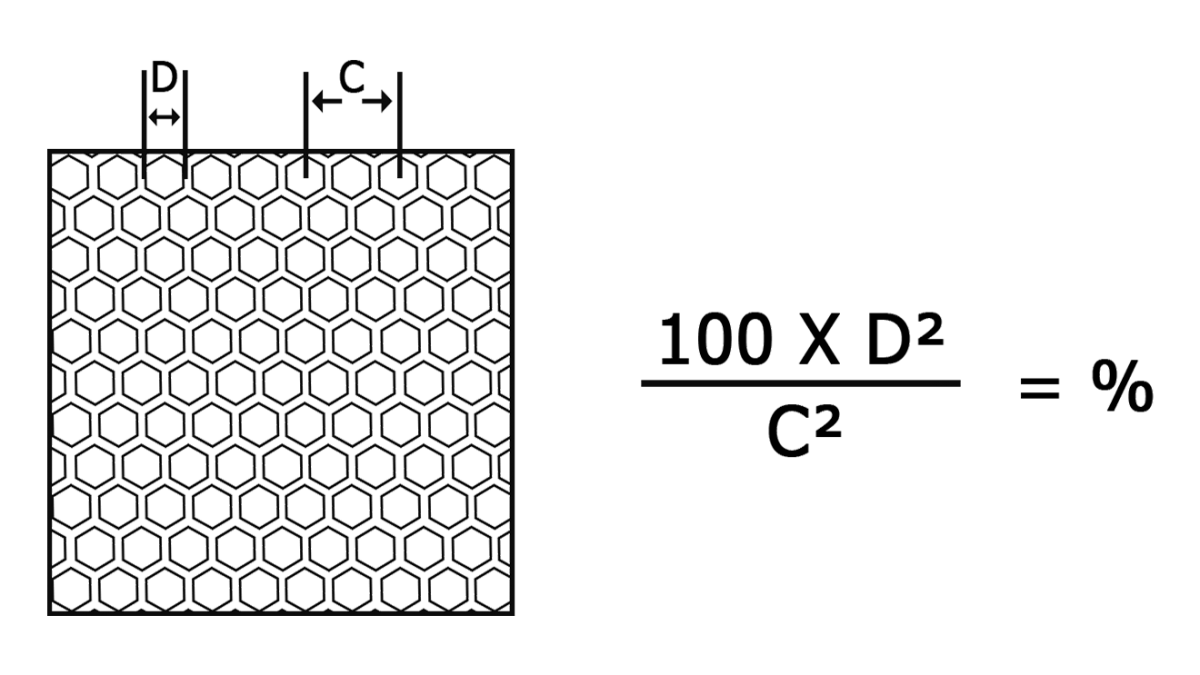

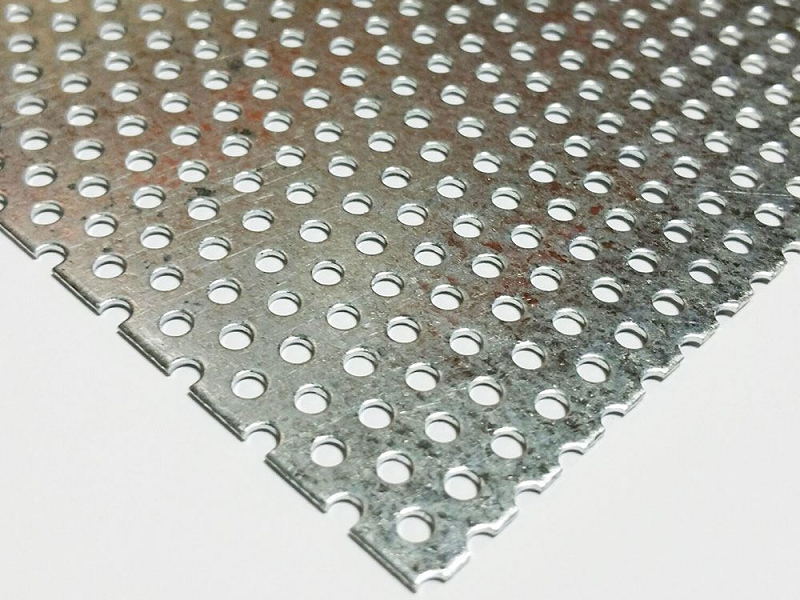

- Round Hole Perforated Metal

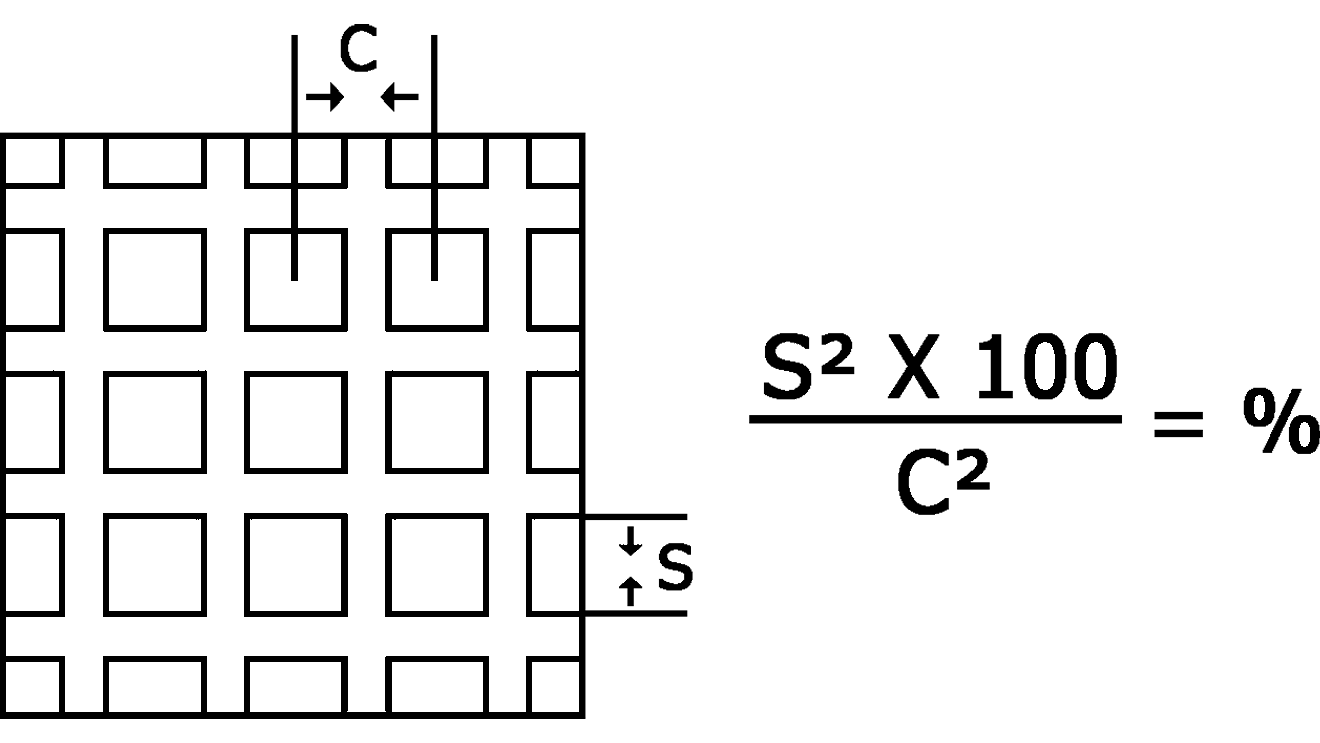

- Square Hole Perforated Metal

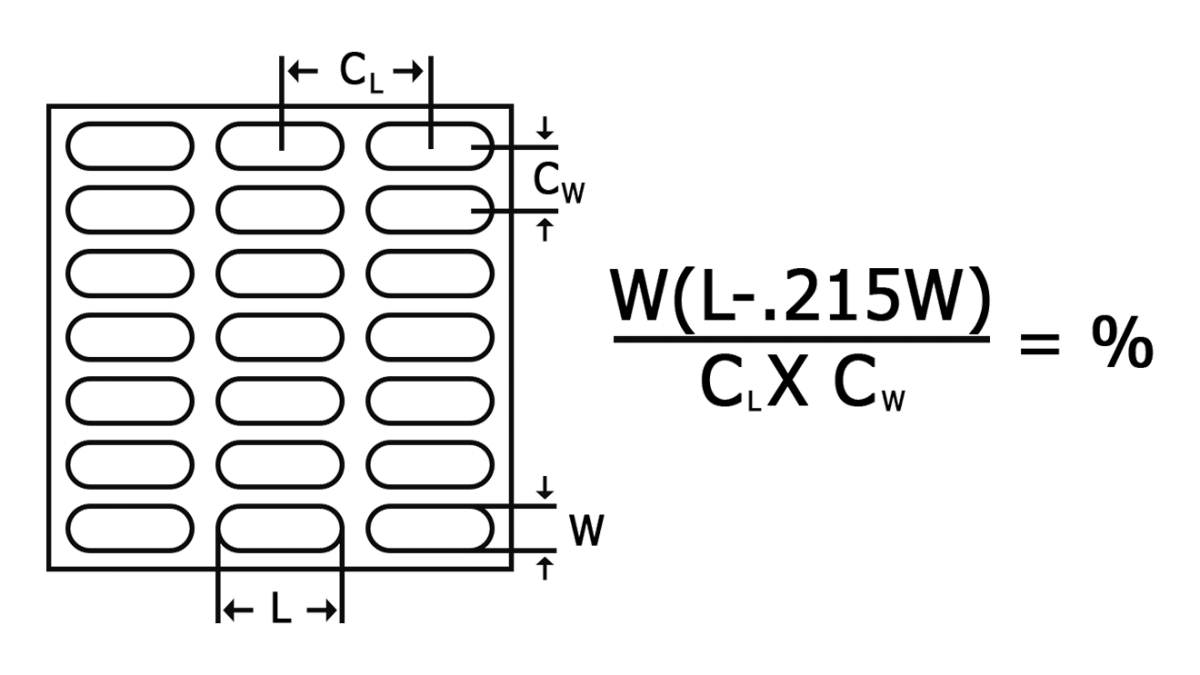

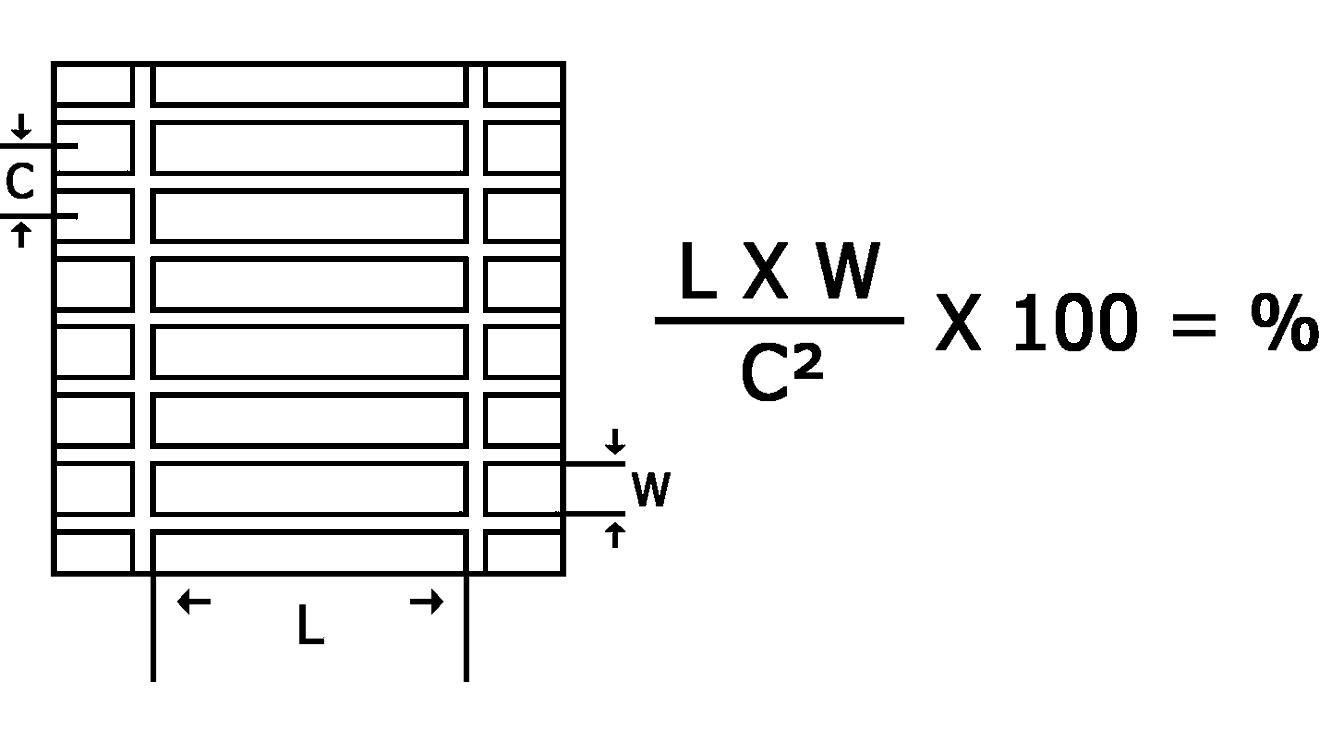

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Open Percent Formulas

Perforation Material

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Steel Perforated Metal

- Galvanized Steel Perforated Metal

- Brass Perforated Metal

Perforated Metal Applications

- Filters

- Perforated Screen Plates

- Aluminum Exterior Building Facades

- Protective Cover For Rquipment

- Perforated Metal Ceilings

- Perforated Metal Infill Panels

- Anti-Skid Perforated Sheet

- Perforated Metal Noise Barrier

347 Stainless Steel

Type 347 stainless steel immune to high temperatures, high strength, stabilized by Columbium and Tantalum. Uses include exhaust manifolds, flash boilers, stack liners, firewalls, pressure vessels and boiler casings.

Principal Design Features: Similar to 321 stainless, 347 uses columbium as a stabilizing element to maximize its principal feature: resistance to intergranular corrosion. It can be used in applications requiring repeated heating in the range of 800 and 1650 F (427-899 C).

Applications: High temperature gaskets and expansion joints, rocket engine parts, aircraft collector rings and exhaust manifolds and chemical production equipment.

Machinability: Slightly tougher than 304 stainless, this material will produce the same tough stringy chips. The use of slow speeds and constant positive feeds will minimize this alloy’s tendency to work harden.

Welding: 347 may be welded by all commonly used fusion and resistance methods. Oxyacetylene welding is not recommended. When necessary, use AWS E/ER347 filler metal.

347 Chemistry

| Carbon | 0.08 max |

| Chromium | 17 - 19 |

| Iron | Balance |

| Manganese | 2 max |

| Nickel | 9 - 13 |

| Niobium | Min:5 x C |

| Phosphorus | 0.045 max |

| Silicon | 1 max |

| Sulphur | 0.03 max |

347 Physical Data

| Density (lb / cu. in.) | 0.29 |

| Specific Gravity | 8.03 |

| Specific Heat (Btu/lb/Deg F - [32-212 Deg F]) | 0.12 |

| Electrical Resistivity (microhm-cm (at 68 Deg F)) | 438 |

| Melting Point (Deg F) | 2600 |

| Modulus of Elasticity Tension | 28 |