Surface Finishing

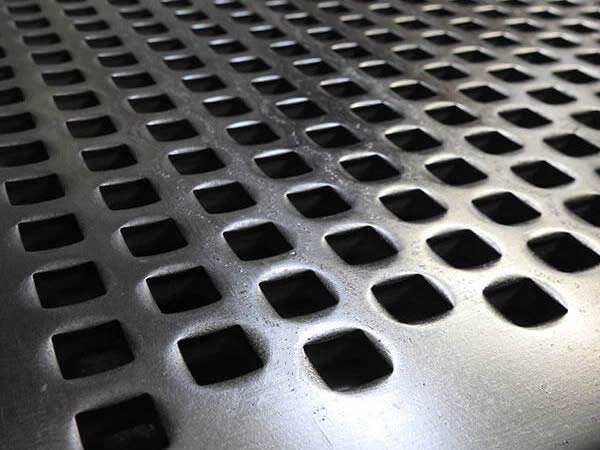

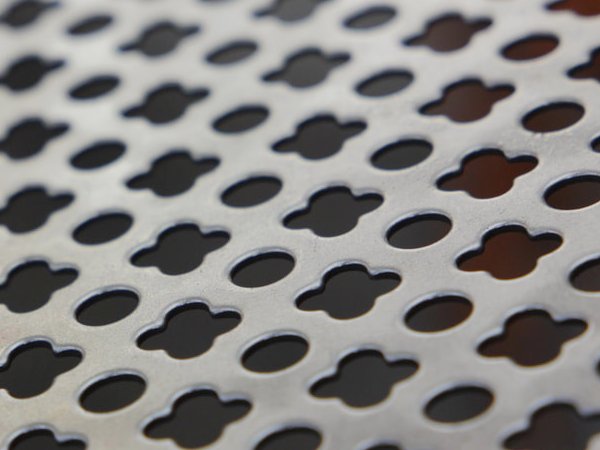

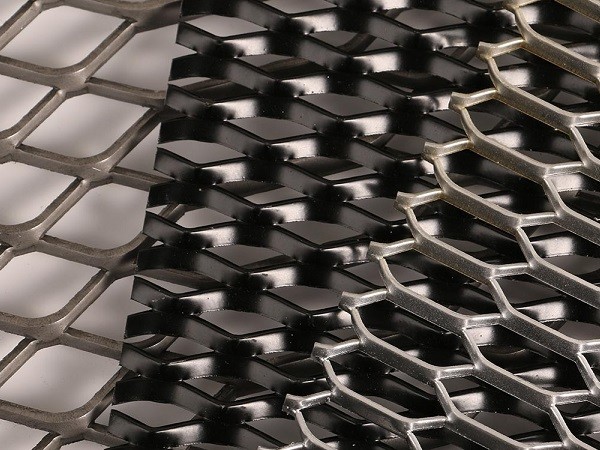

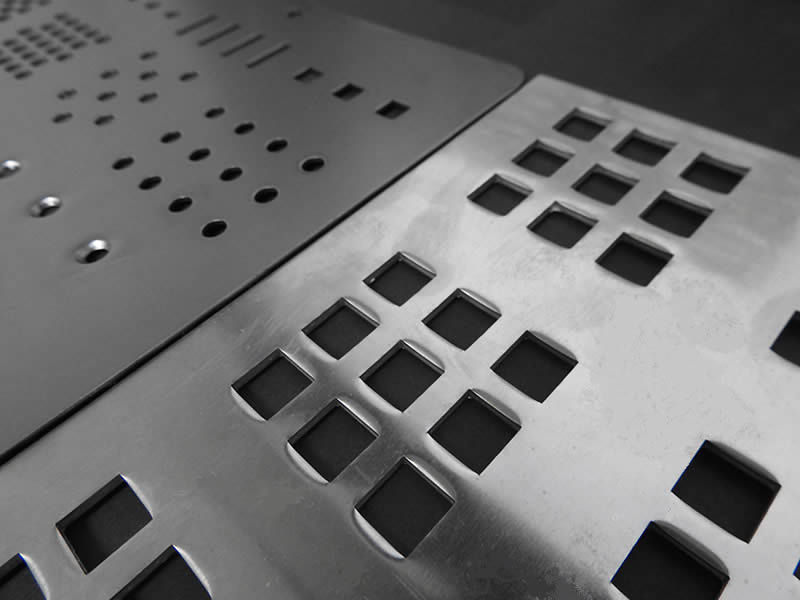

We have professional purchasing and quality control teams. We not only make metal wire mesh, perforated metal sheets, Expanded metal mesh, perforated metal filter elements, but also strictly choose reliable factories for all kinds of surface finishing that our customers often need, such as hot dipped galvanizing,pickling, electrolytic polishing, powder coating, PVDF coating and anodizing.

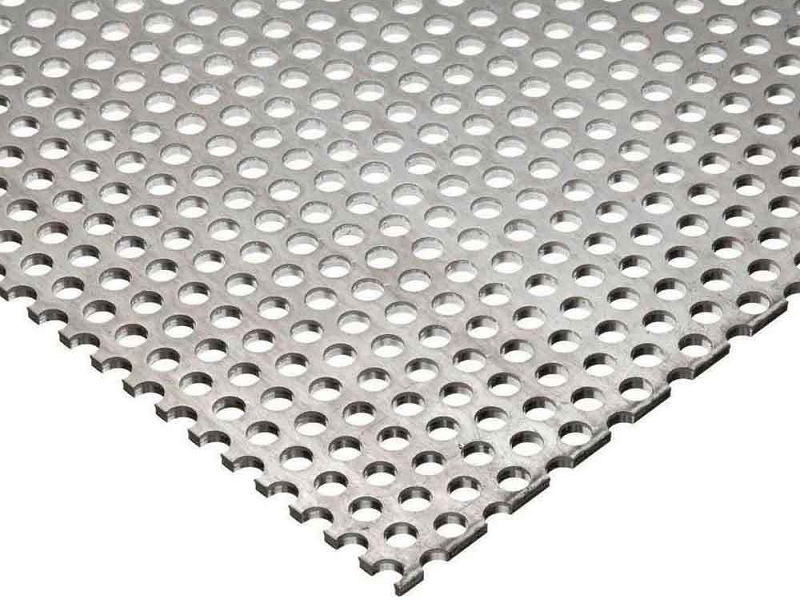

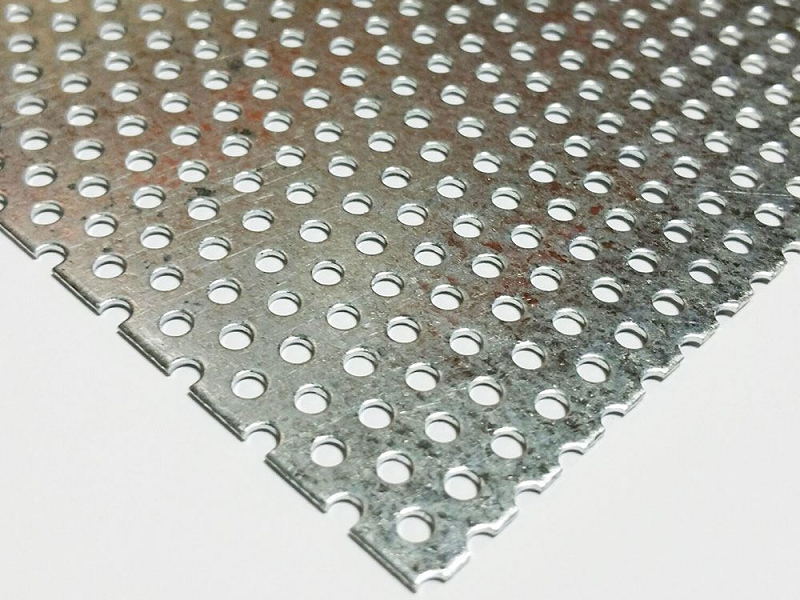

Hot dip galvanizing is a form of galvanizing in which a surface treated metal is immersed in a bath of molten zinc at a temperature of about 450 °C (842 °F). The zinc forms a layer of compounds on the metal surface, a process that helps to protect the metal from corrosion. The hot-dip galvanizing process is divided into three basic steps: surface treatment, galvanizing, and inspection. Compared with other galvanized steel, hot dip galvanizing process is relatively cheap, the product is corrosion resistant, so it is widely used in agriculture, industry, automobile, construction, solar energy and other wet or corrosive environment. For example, our Anti-Skid Perforated Sheet is galvanized in this way.

Strictly refer to international standard ISO 1461:1999, American Society for Testing Materials ASTM A123/A123M and domestic standard GB/T 13912-2002 testing requirements.

Advantages:

Low cost

Thick zinc coating

Strong corrosion resistance

The service life can be greatly improved by galvanizing process

Coating adhesion is good, after plating, it can also undergo properly welding, coating and other processing

Disadvantages:

The working environment is poor and polluted.

The galvanized coating is thick but uneven.

Pickling

One method of removing scale oxide and corrosives from the surface of steel using acid solutions is commonly referred to as pickling. It can clean the oil on the metal surface and play the role of cleaning. It is the pre-treatment work of electroplating, rolling and other processes. Our wedge wire screens are prepared with pickling.

We strictly comply with the international standard ISO 27831 and domestic standard JB/T 6978 testing requirements.

Advantages:

A process that is simple to operate, low cost and relatively easy.

Make the surface cleaner and smoother.

After pickling, the work piece surface residue is less and the surface quality is higher.

Disadvantages:

Pickling is difficult to handle due to its corrosive nature, and it is not suitable for all steels.

The process of waste acid treatment and resource regeneration after pickling is complex.

Pickling treatment will also cause poor galvanized layer adhesion in the later stage.

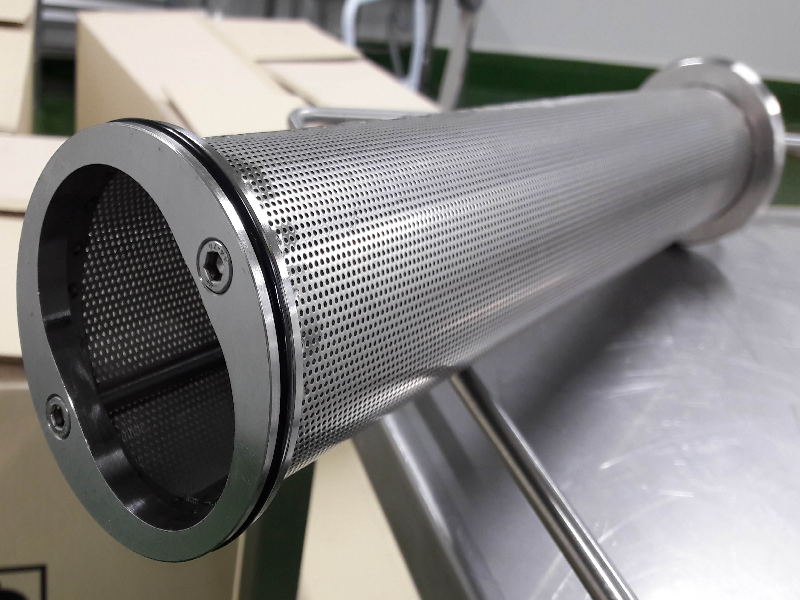

Electrolytic Polishing

It is an electrochemical finishing process, which takes the polished work piece as the anode and the insoluble metal as the cathode. The two poles are immersed in the electrolytic cell at the same time, the selective anodic dissolution is generated through direct current ionization reaction, so as to achieve the effect of removing fine burs and increasing the brightness of the work piece surface. The process leaves a shiny, smooth, ultra-clean surface finish. Filters after electrolytic polishing, the surface of the products is bright and beautiful.

We strictly comply with ASTM B912 and YB/T 4377-2014 testing requirements.

Advantages:

Consistent color and lasting luster.

High production efficiency, low cost, can be mass processing.

Enhance the corrosion resistance of work piece surface, suitable for all stainless steel materials.

Disadvantages:

There are many parameters affecting electrolytic polishing, so it is difficult to find the correct parameters.

It is difficult to obtain good results for samples such as cast iron and inclusions.

Electrolyte composition is complex, need to pay attention to safety operation when using.

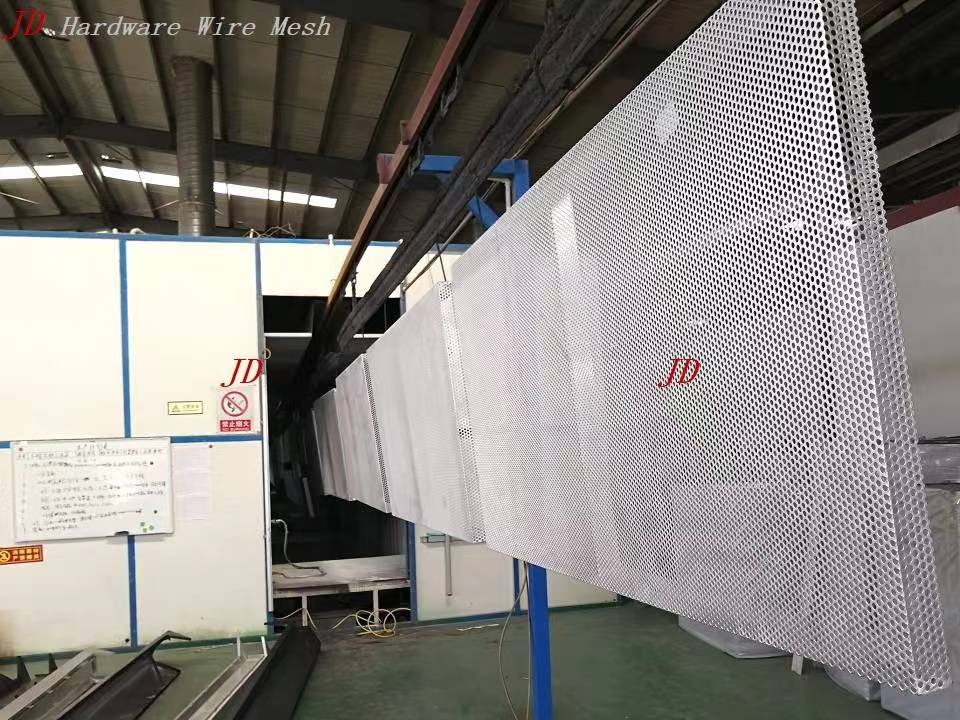

Powder Coating

Powder coating is the use of powder spraying equipment to spray the powder to the surface of the workpiece, under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece, forming a powder coating.It will then form a protective film on the surface after curing and drying. Our decorative aluminum perforated panel, decorative perforated plate will use the powder coating process.

Strictly in accordance with ISO 8130 and GB/T 21776-2008 testing standards.

Advantages:

Powder coating tends to produce a uniform coating for increased durability.

It is resistant to impact, chemical corrosion and abrasion.

A variety of finishes to choose from, rich color style.

High utilization rate, 100% utilization, reduce environmental pollution.

Disadvantages:

High initial investment, and need to buy spray guns, special spray rooms and curing furnaces and other equipment.

Large parts take longer to dry and cure.

It is still challenging to produce thin coatings or multi-color coatings.

PVDF Coating

Polyvinyl difluoride (PVDF) coatings are sprayed in a spray room through a liquid spray gun and are one of the most commonly used commercial and industrial coatings on the market. PVDF is a fluoropolymers resin that is highly inert and stable and has excellent resistance to weathering caused by sunlight, moisture or temperature. Our decorative perforated plates often use this process.

We strictly test product quality according to HG/T 3793-2019 standard.

Advantages:

PVDF coating is resistant to UV radiation, has excellent color retention and will not fade with time.

The coating has good adhesion, abrasion resistance and long service life.

The coating is resistant to most chemicals and solvents, acids and corrosion.

In addition to being able to self-extinguish, the PVDF coated material also produces little smoke in the event of a fire.

Disadvantages:

Only matte finishes are available, while powder coatings can come in a variety of colors and finishes.

More expensive than powder coatings.

Anodizing

Mainly aluminum anodizing, is the use of electrochemical principle, to generate a layer of AL₂O₃ (alumina) film on the surface of aluminum and aluminum alloy. This oxide film has special properties such as protection, decoration, insulation and wear resistance. Aluminum is well suited for anodizing, and other nonferrous metals (e.g., magnesium and titanium) are also suitable for anodizing. However, this alumina is not applied to the surface like paint or electroplating. Instead, it is fully incorporated into the underlying sheet, so it does not crumble or flake. Decorative aluminum punch plates often use this method to form an alumina film to protect the perforated plate from corrosion.

We strictly implement GB/T 12967 standard and MIL-8625F detection methods.

Advantages:

Easy to maintain and can be cleaned with water and mild cleaners to restore the original luster.

Resistant to corrosion and wear caused by long-term use.

The anodized film does not peel off because it is actually part of the metal.

Environment, health and safety, it is one of the most environmentally friendly industrial processes.

Disadvantages:

Anodized films are typically only available in matte and polished finishes.

There may be 95% match between different batches, and it is difficult to be completely consistent between different batches.

In urban areas, surfaces may be vulnerable to acidic contaminants.