Hole Pattern

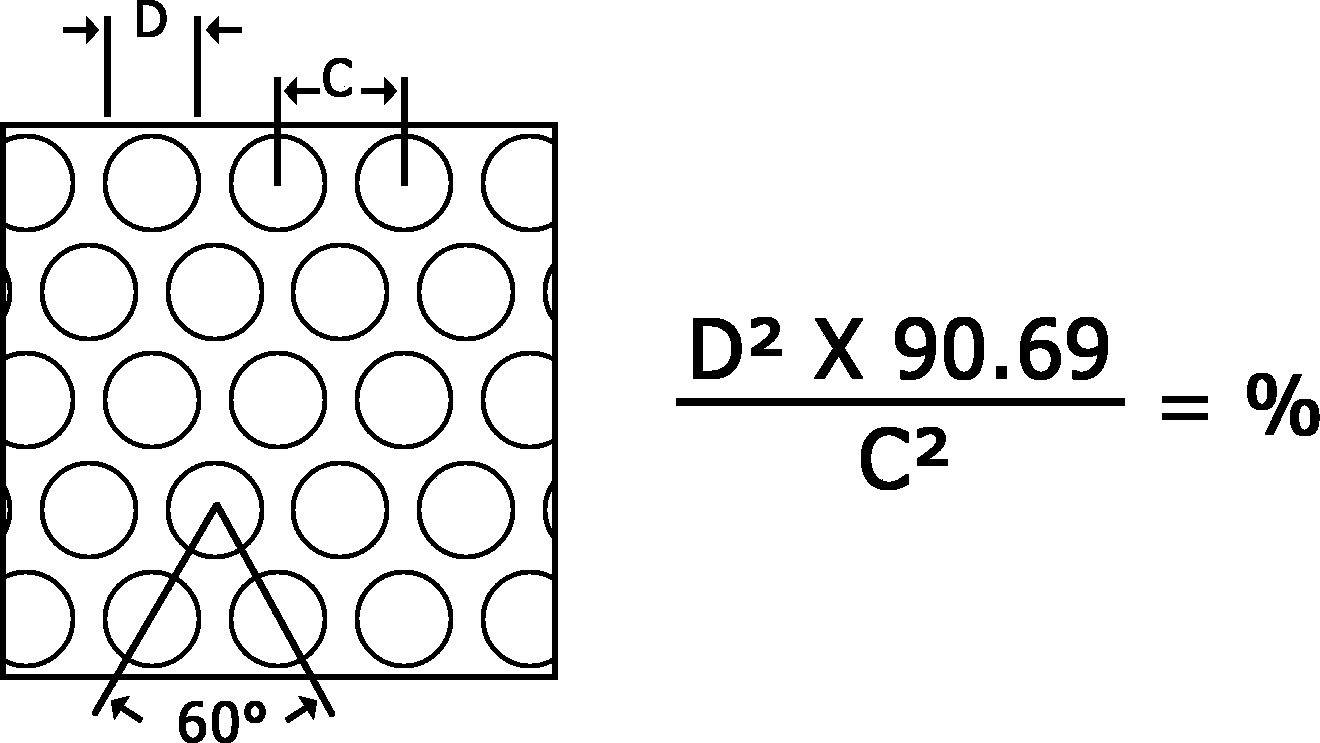

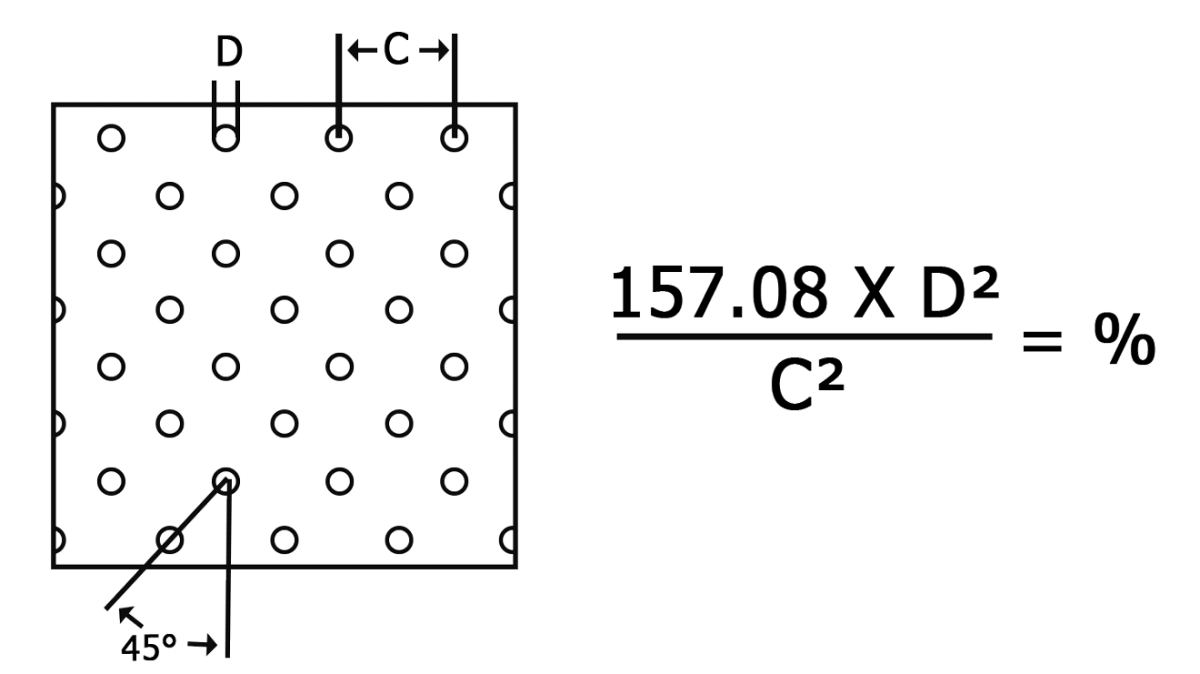

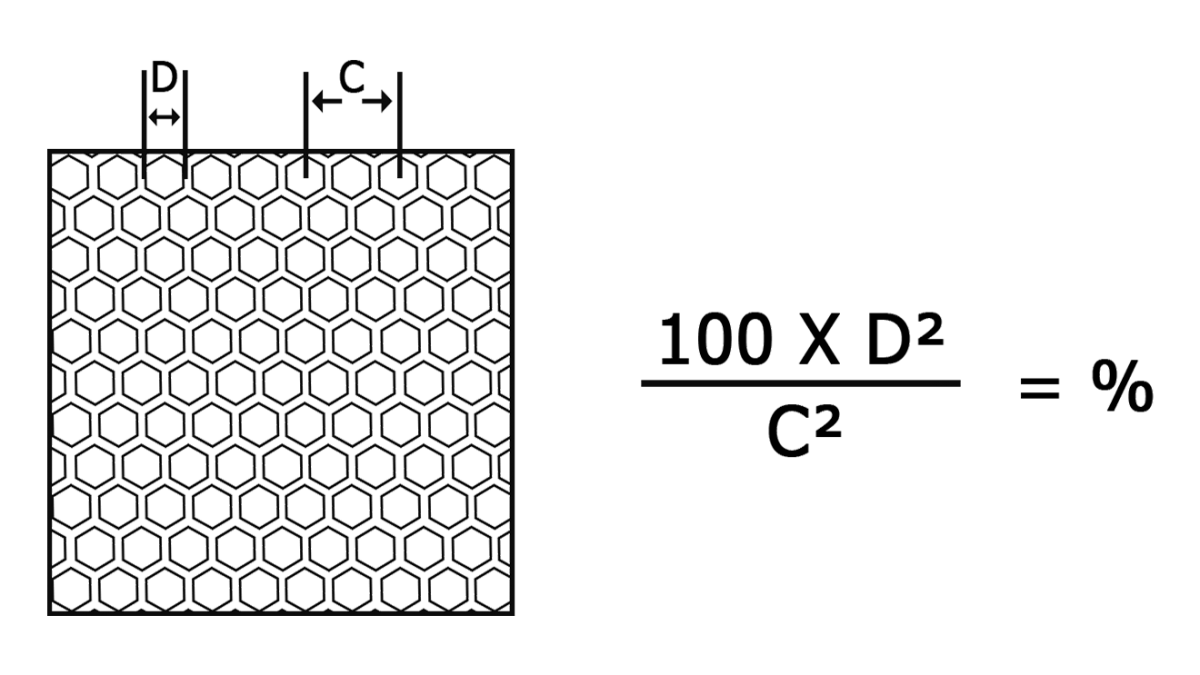

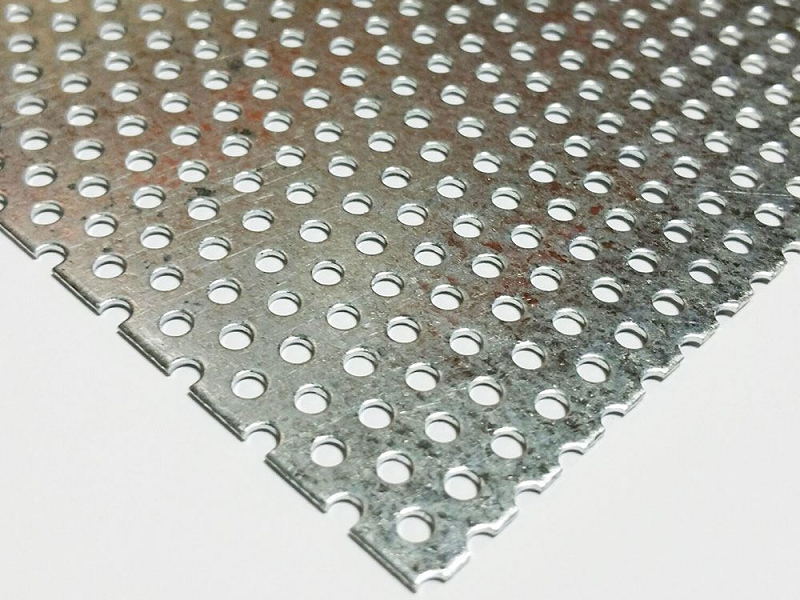

- Round Hole Perforated Metal

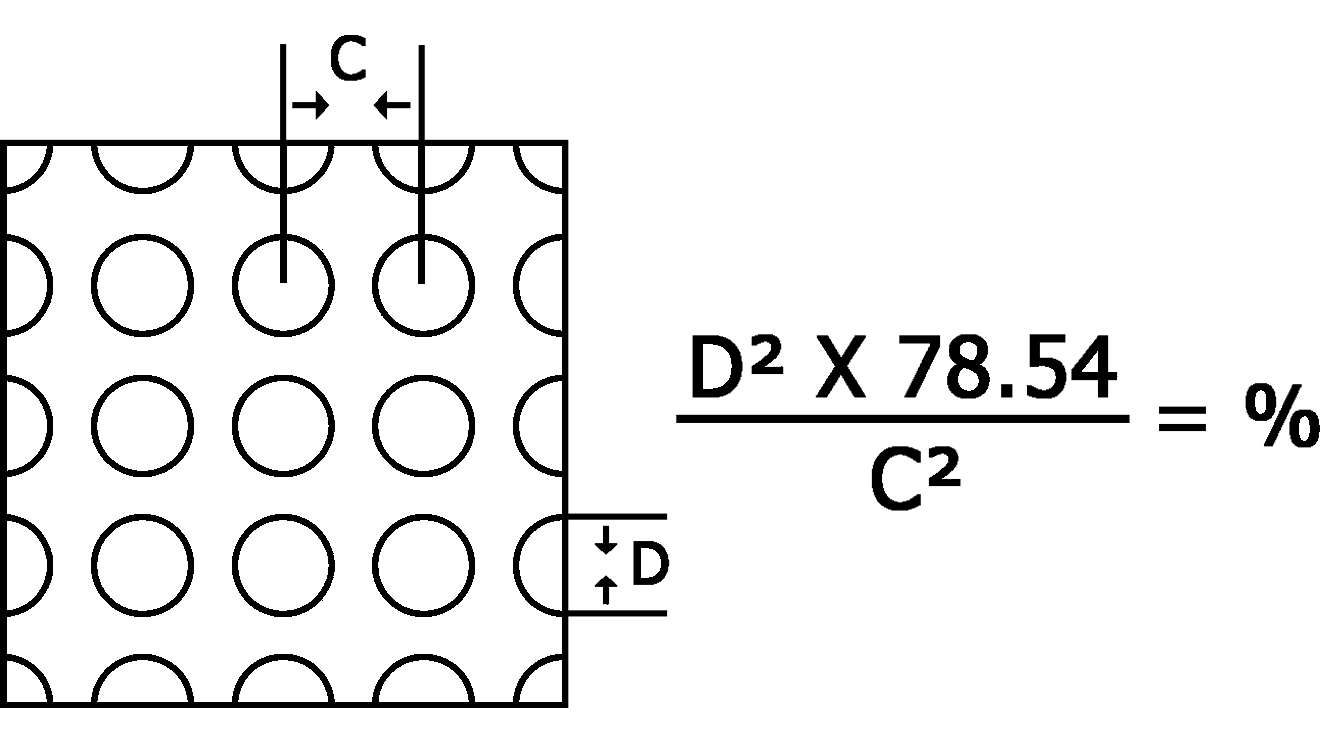

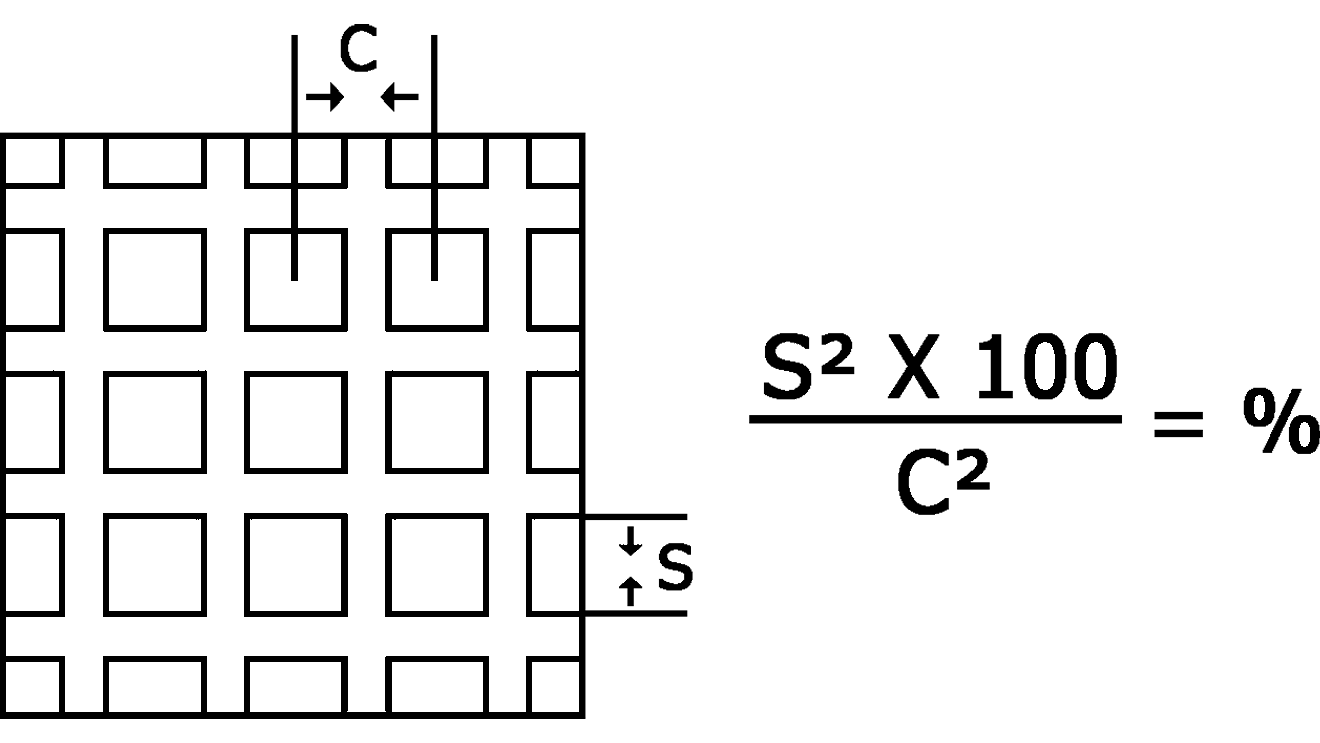

- Square Hole Perforated Metal

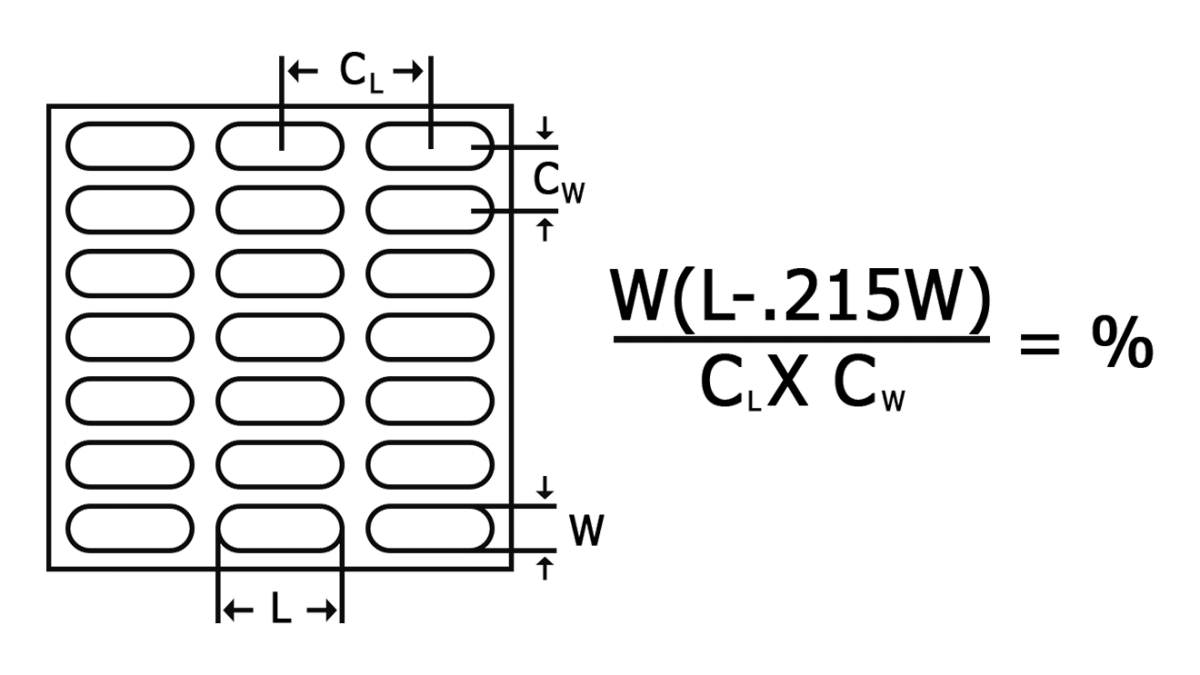

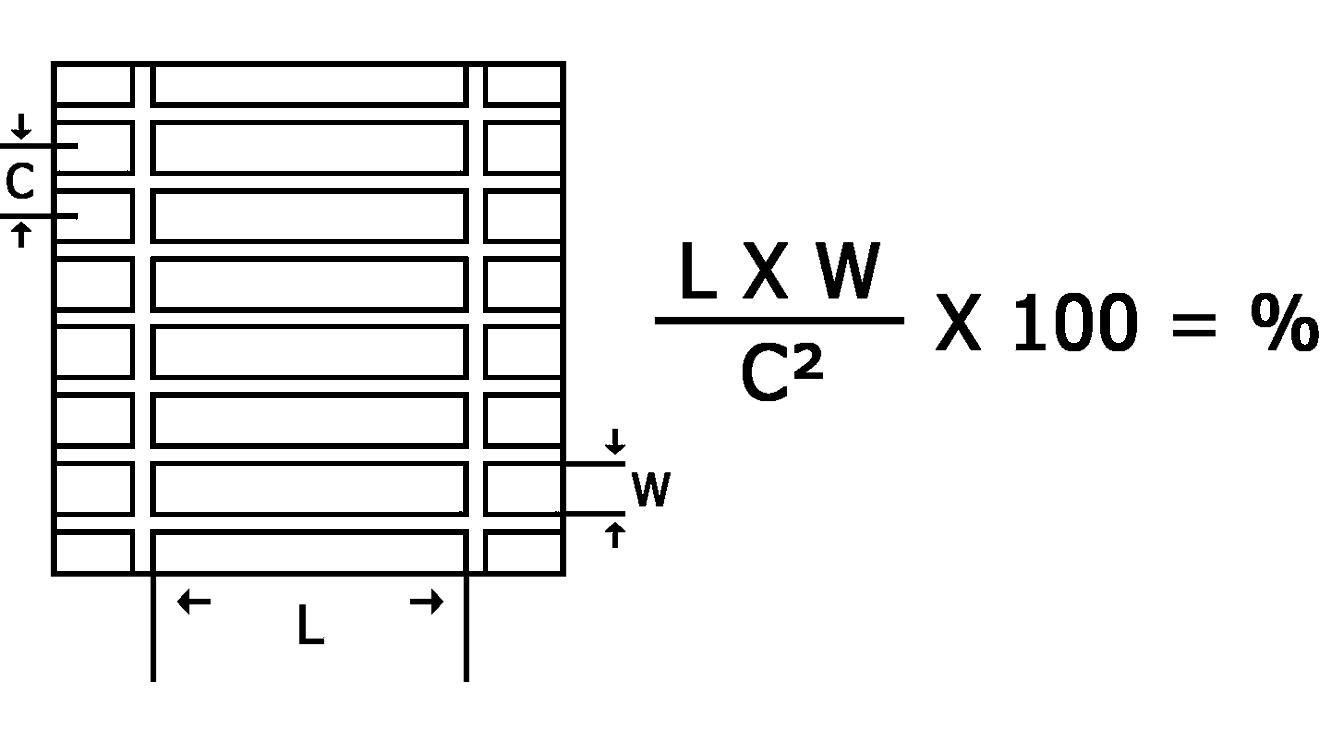

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Open Percent Formulas

Perforation Material

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Steel Perforated Metal

- Galvanized Steel Perforated Metal

- Brass Perforated Metal

Perforated Metal Applications

- Filters

- Perforated Screen Plates

- Aluminum Exterior Building Facades

- Protective Cover For Rquipment

- Perforated Metal Ceilings

- Perforated Metal Infill Panels

- Anti-Skid Perforated Sheet

- Perforated Metal Noise Barrier

Contact Us

904L Stainless Steel

Principal Design Features: 904L is an austenitic stainless steel designed for moderate to high corrosion resistance. Its low carbon content improves cleanliness and weld strength.

Applications: Utility scrubber assemblies, acid and fertilizer production equipment.

Machinability: Slow speeds and positive feeds will minimize this alloy’s tendency to work harden and glaze. Use chip breakers where possible to overcome problems with long draggy chips.

Welding: Most common fusion and resistance methods may be employed. For maximum corrosion resistance, it is recommended to use filler metals of equal or higher alloy content.

904L Chemistry

| Carbon | 0.02 max |

| Chromium | 19 – 23 |

| Copper | 1 – 2 |

| Iron | 2 max |

| Nickel | Balance |

| Manganese | 2 max |

| Molybdenum | 4 – 5 |

| Nickel | 23 – 28 |

| Phosphorus | 0.045 max |

| Silicon | 1 max |

| Sulphur | 0.035 max |

904L Physical Data

| Density (lb / cu. in.) | 0.285 |

| Specific Gravity | 7.9 |

| Specific Heat (Btu/lb/Deg F – [32-212 Deg F]) | 0.12 |

| Electrical Resistivity (microhm-cm (at 68 Deg F)) | 480 |

| Modulus of Elasticity Tension | 28.4 |