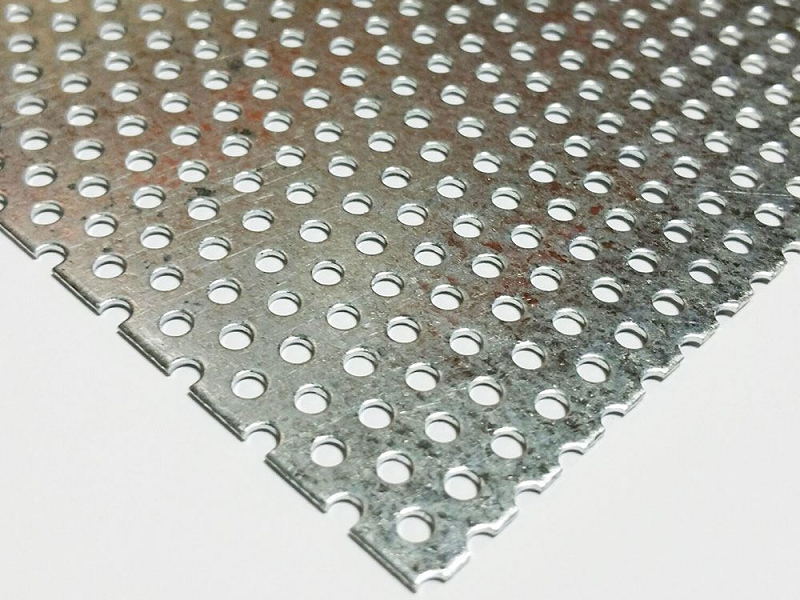

Hole Pattern

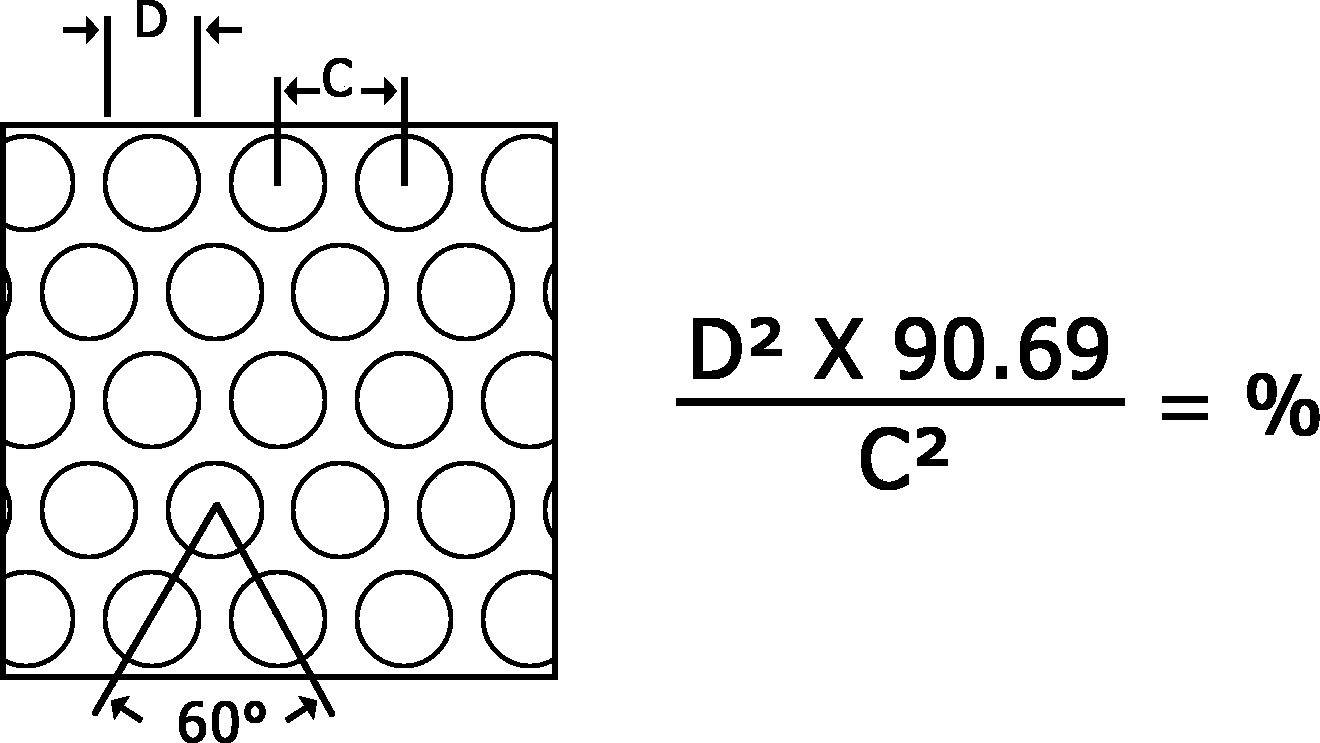

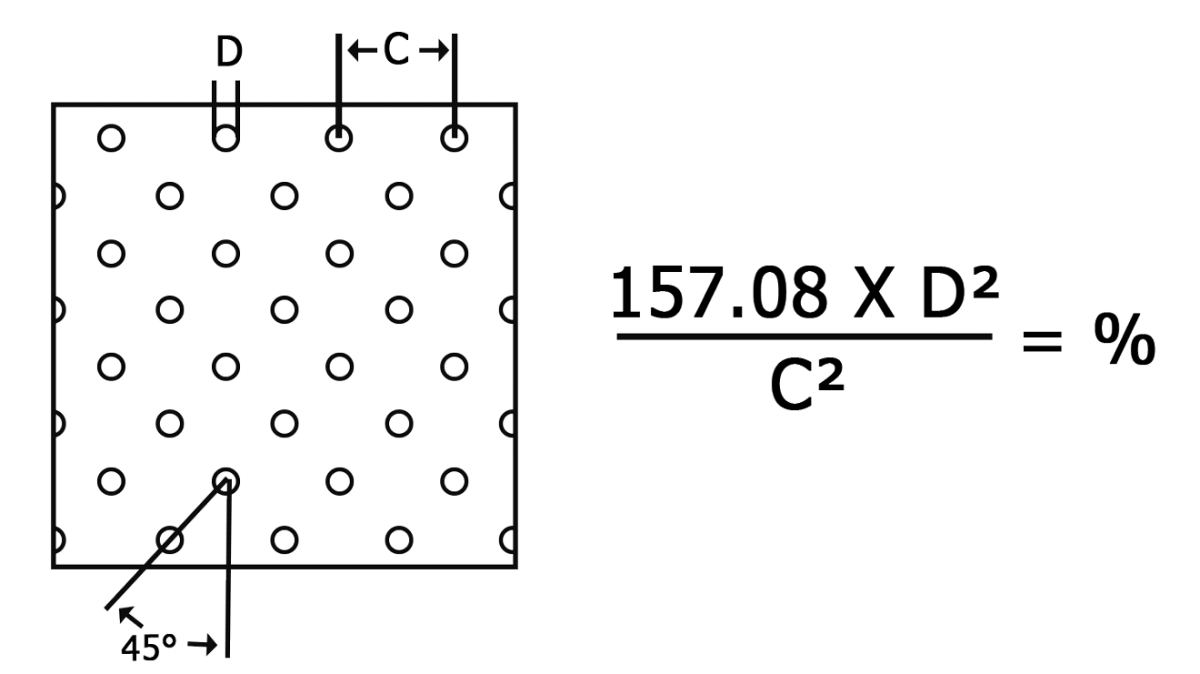

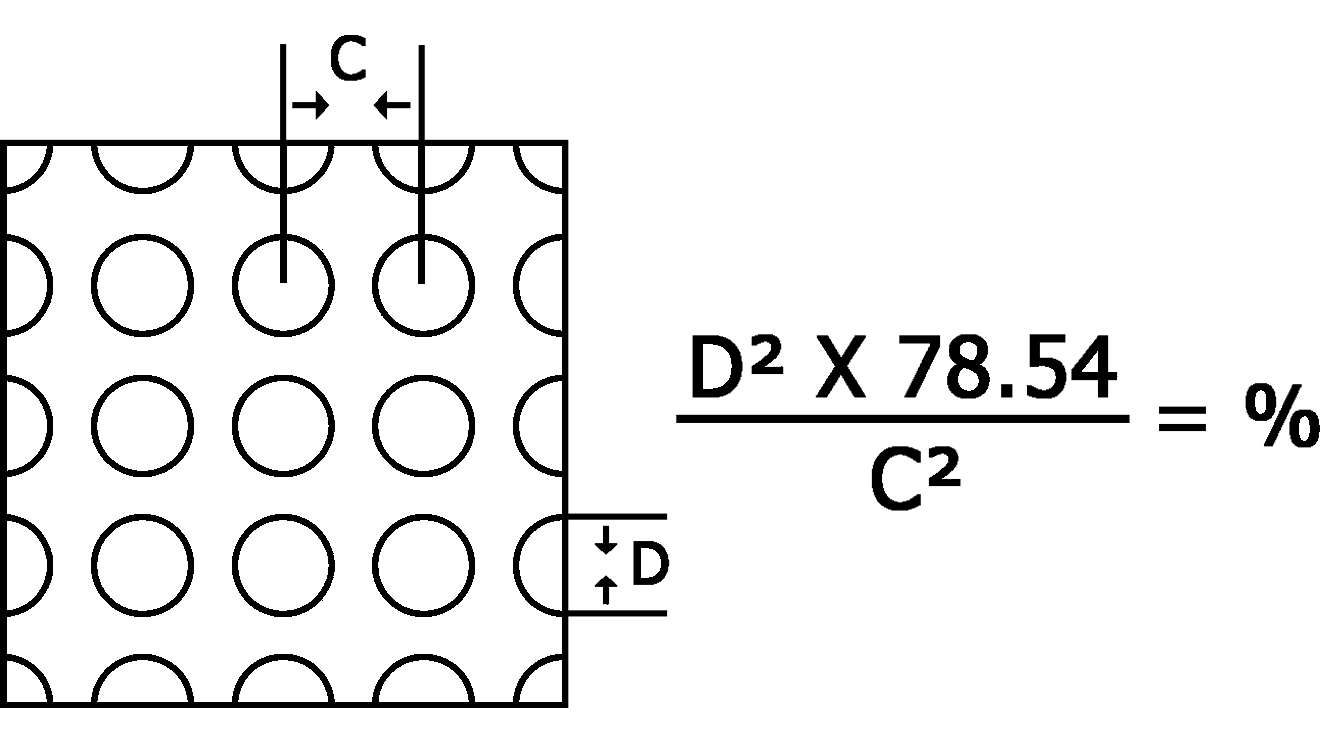

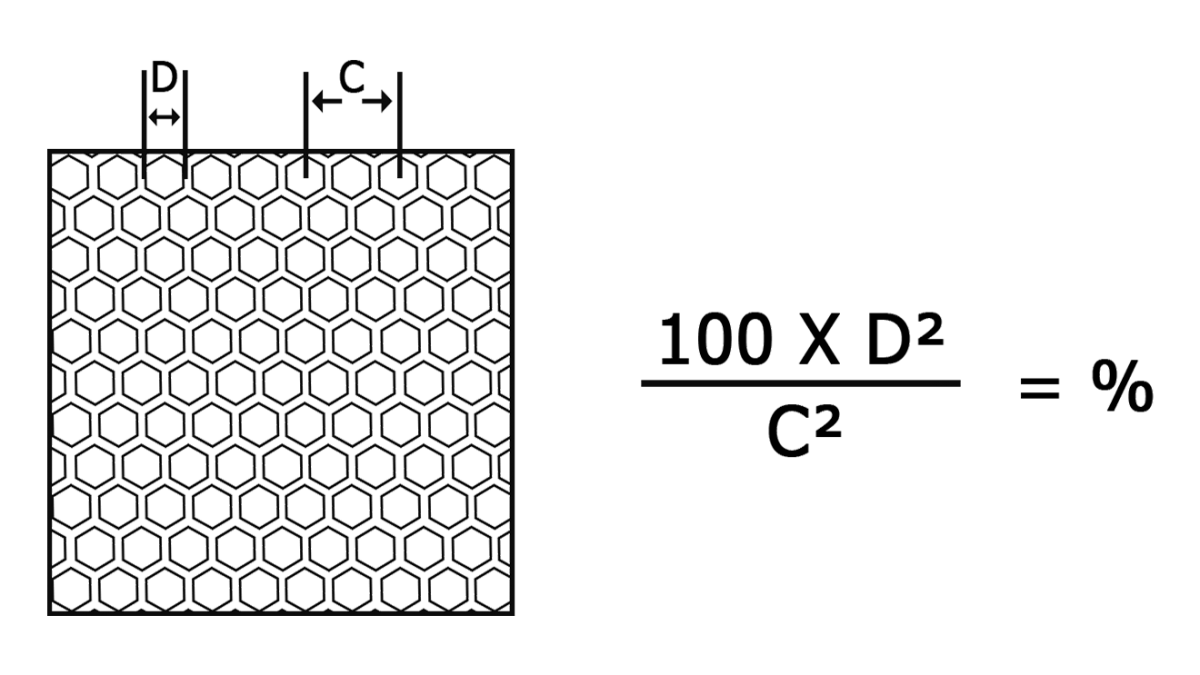

- Round Hole Perforated Metal

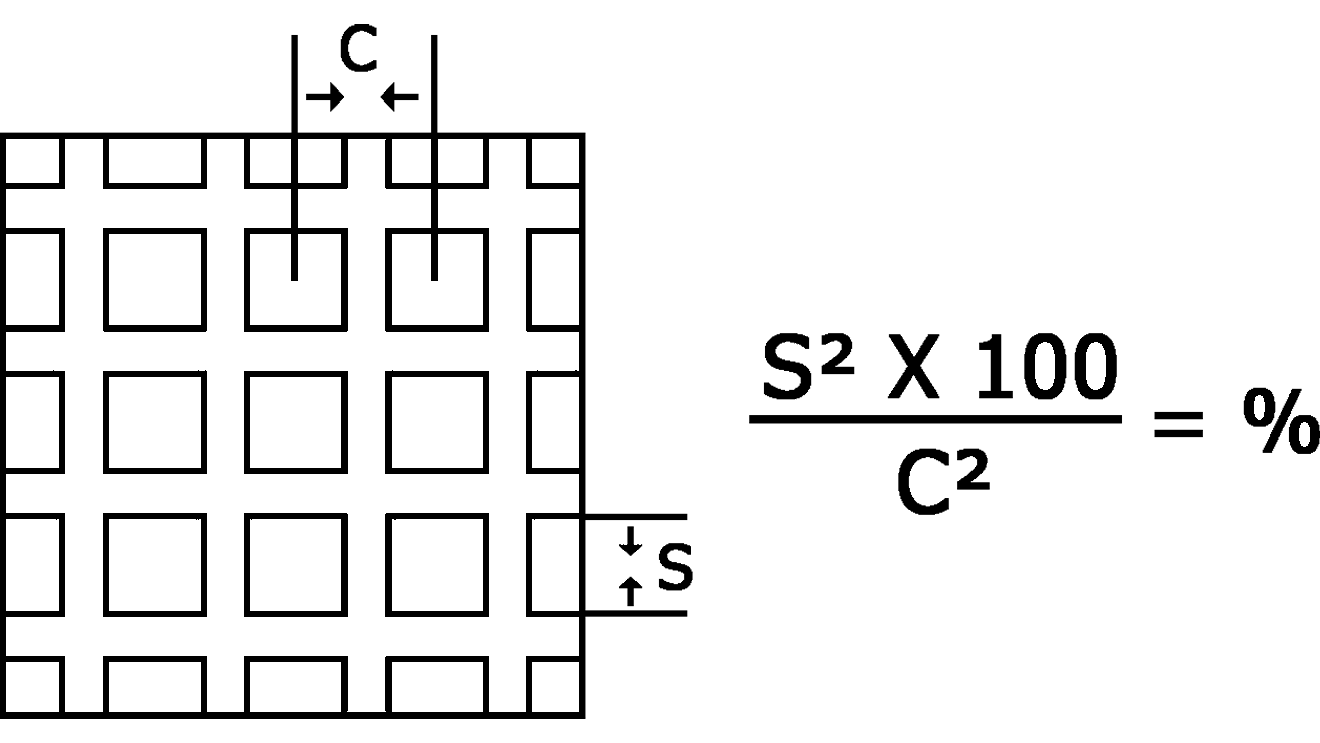

- Square Hole Perforated Metal

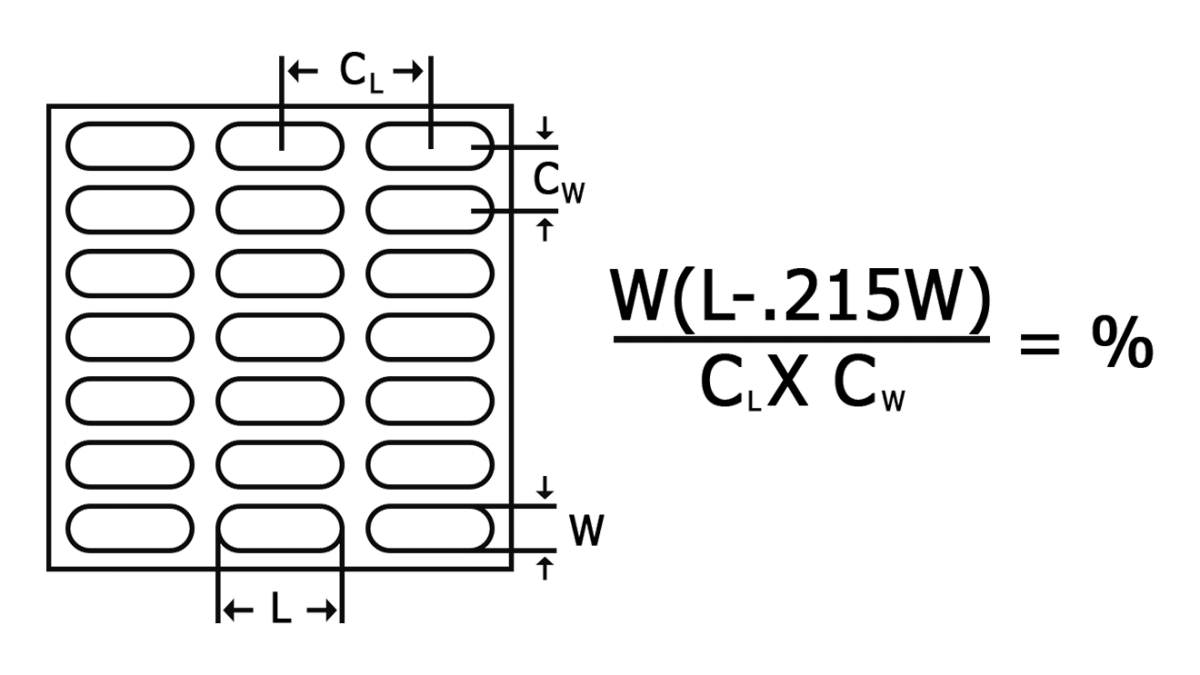

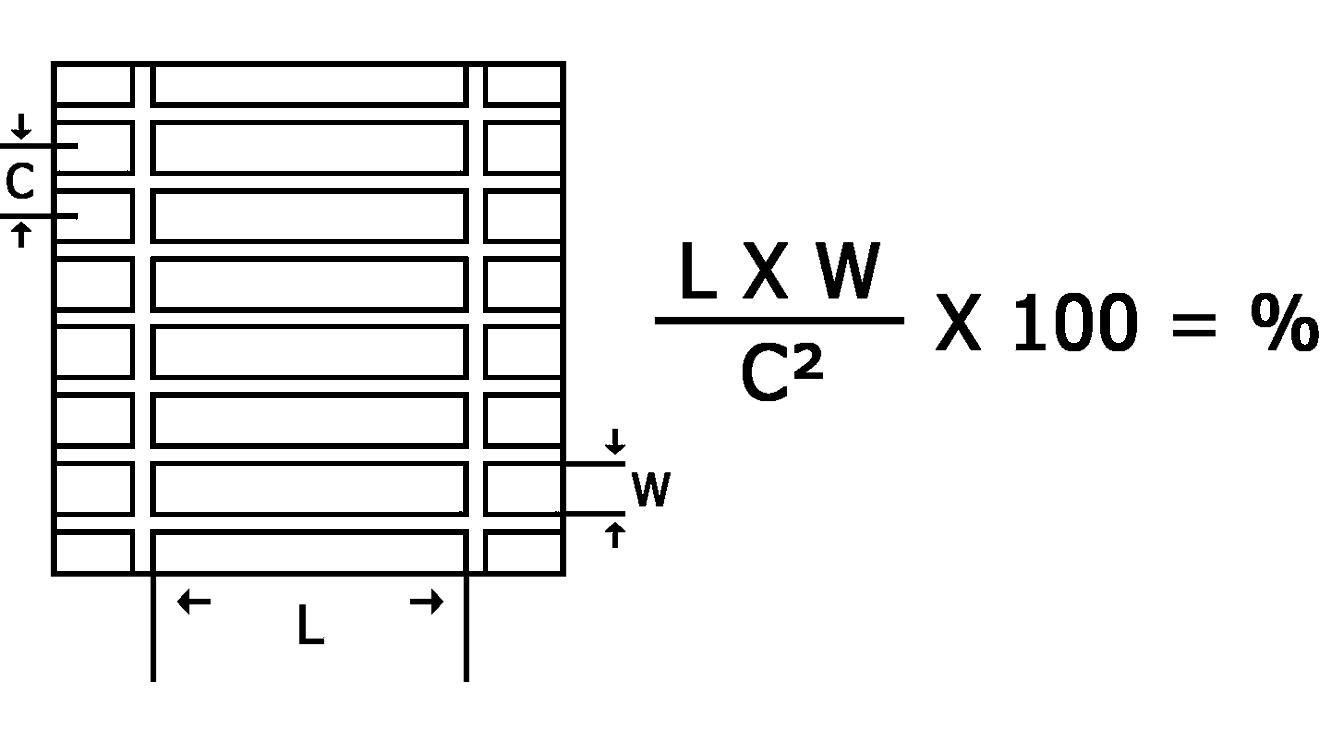

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Open Percent Formulas

Perforation Material

- 904L Stainless Steel

- 430 Stainless Steel Wire Cloth & Grating

- 410 Stainless Steel

- 347 Stainless Steel

- 321 Stainless Steel

- 316/316L Stainless Steel

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Steel Perforated Metal

- Galvanized Steel Perforated Metal

- Brass Perforated Metal

Perforated Metal Applications

- Filters

- Perforated Screen Plates

- Protective Cover For Rquipment

- Noise Control

- Perforated Metal Ceilings

- Fill Panel Applications

- Aluminum Exterior Building Facades

- Anti-Skid Perforated Sheet

310 Stainless Steel

Principal Design Features: The strength of this alloy is a combination of good strength and corrosion resistance in temperatures up to 2100 F (1149 C). Due to its relatively high chromium and nickel content it is superior in most environments to 304 or 309 stainless.

Applications: Oven linings, boiler baffles, kilns, lead pots, radiant tubes, annealing covers, saggers, burners, combustion tubes, refractory anchor bolts, fire box sheets, furnace components and other high temperature containers.

Machinability: This alloy machines similarly to type 304 stainless. Its chips are stringy and it will work harden rapidly. It is necessary to keep the tool cutting at all times and use chip breakers.

Welding: Most of the austenitic stainless steels can be readily welded using fusion or resistance methods. Oxyacetylene welding is not recommended. Filler metal should be AWS E/ER 310.

310 Chemistry

| Carbon | 0.25 max |

| Chromium | 24 - 26 |

| Iron | Balance |

| Manganese | 2 max |

| Molybdenum | 2 - 3 |

| Nickel | 19 - 22 |

| Phosphorus | 0.045 max |

| Silicon | 1.5 max |

| Sulphur | 0.03 max |

310 Physical Data

| Density (lb / cu. in.) | 0.289 |

| Specific Gravity | 7.9 |

| Specific Heat (Btu/lb/Deg F - [32-212 Deg F]) | 0.12 |

| Electrical Resistivity (microhm-cm (at 68 Deg F)) | 468 |

| Melting Point (Deg F) | 2650 |

| Modulus of Elasticity Tension | 30 |