Hole Pattern

- Round Hole Perforated Metal

- Square Hole Perforated Metal

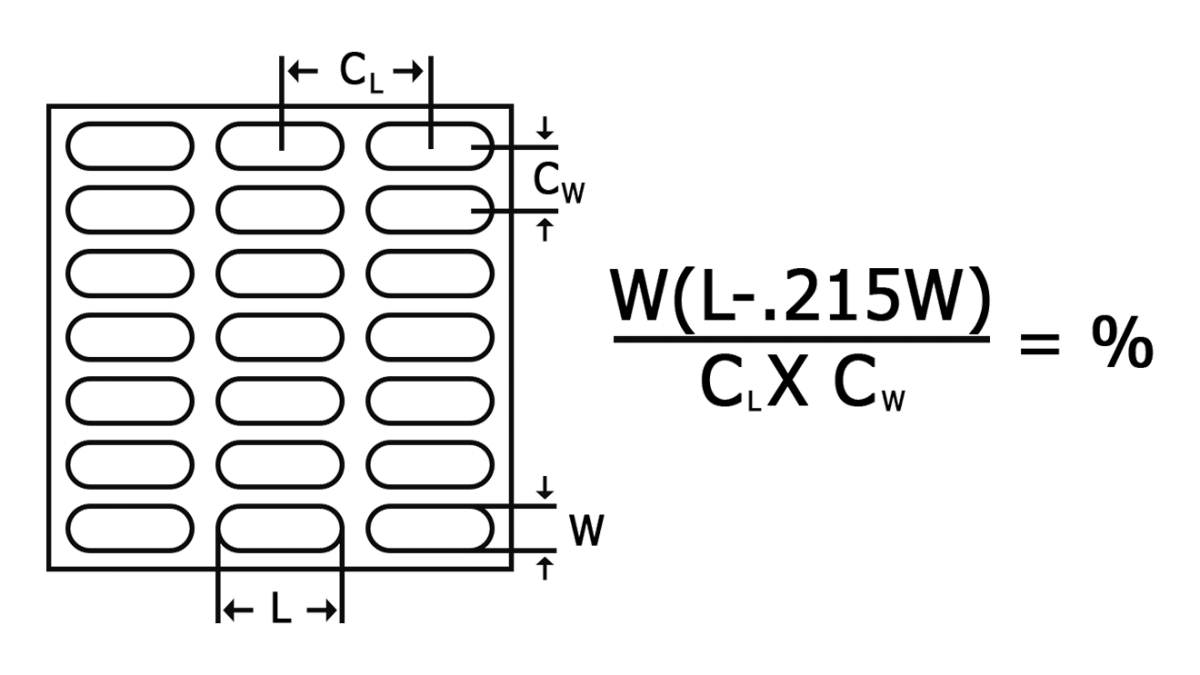

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Expanded Metal Mesh

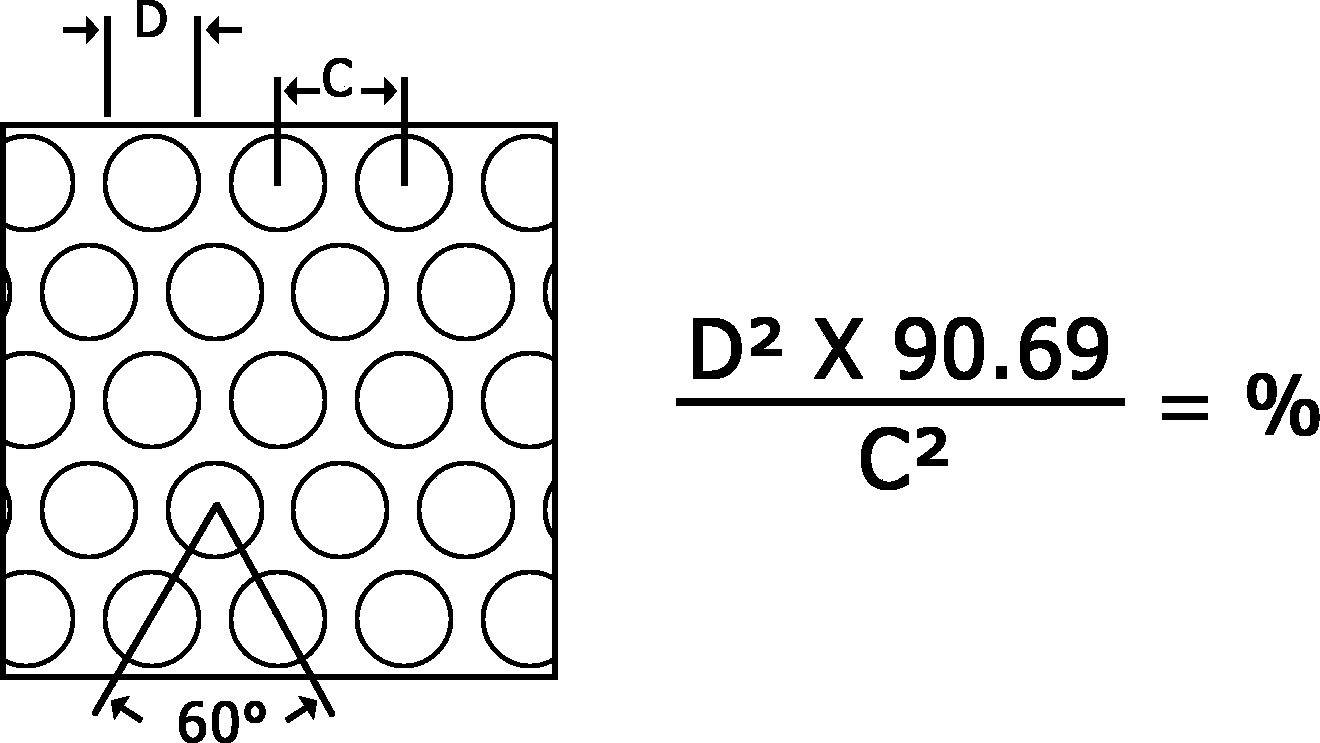

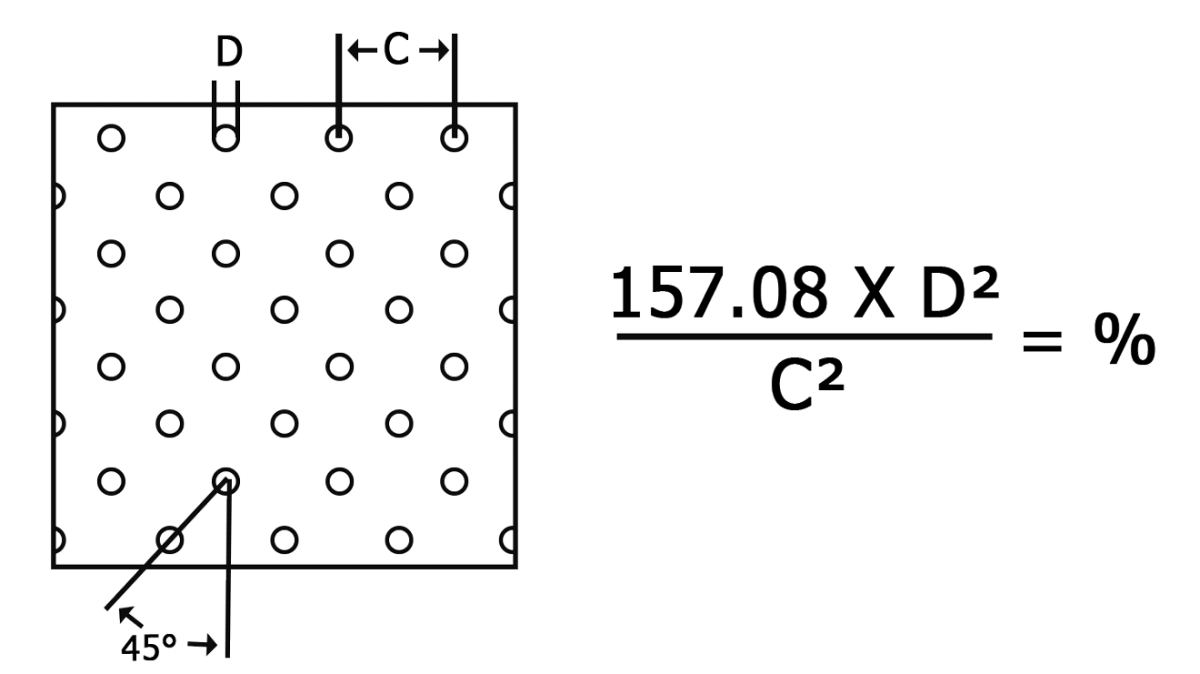

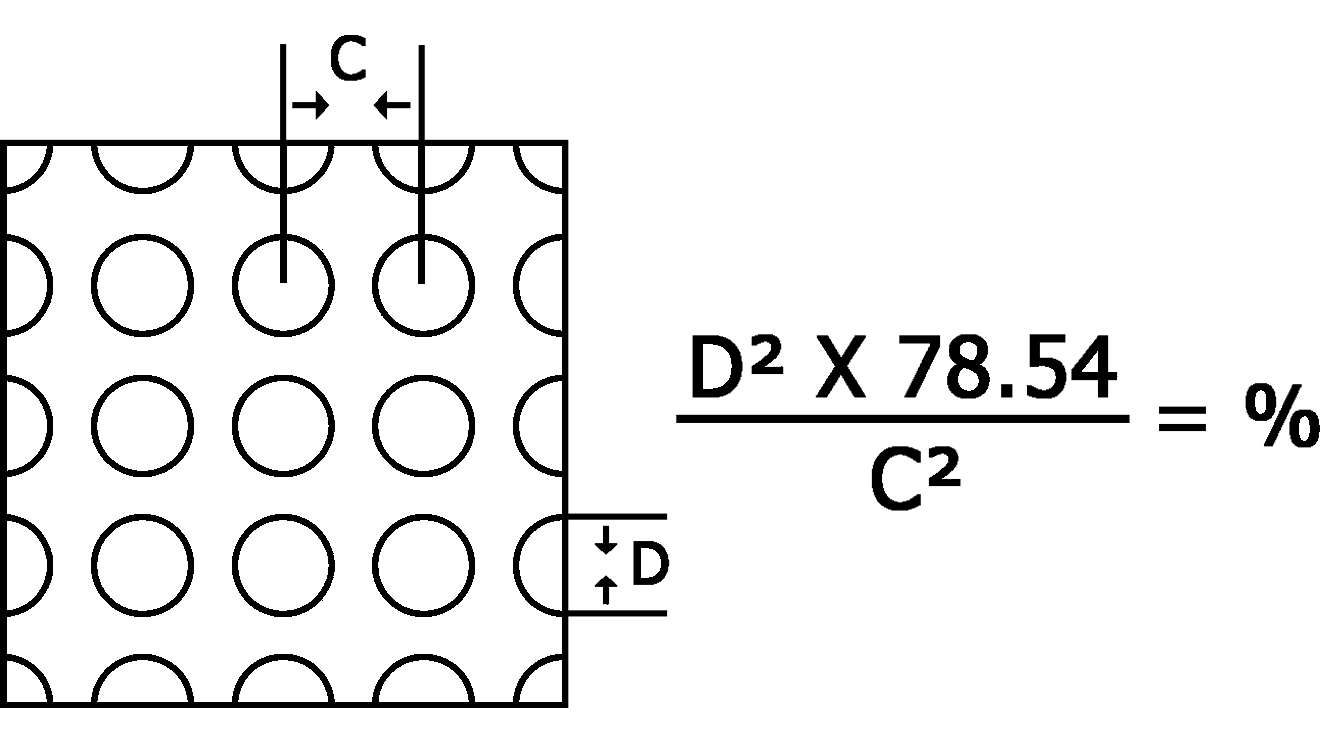

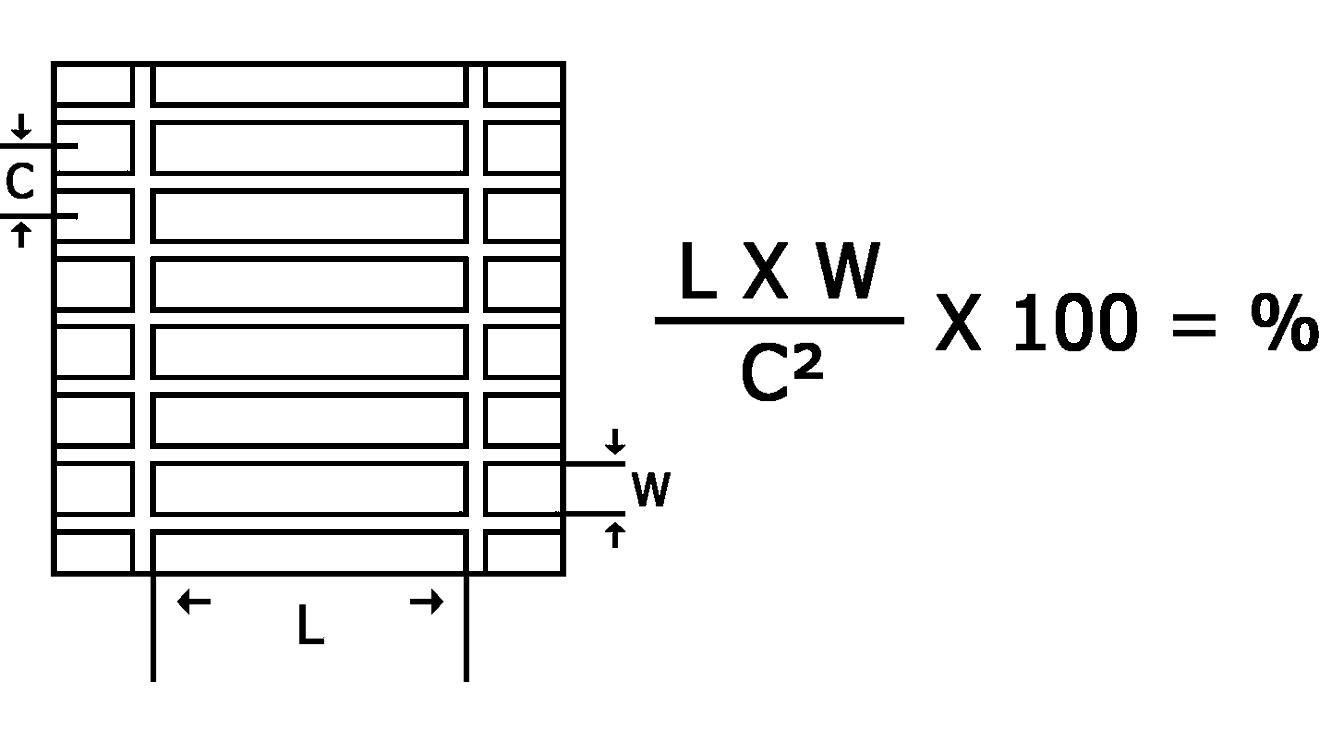

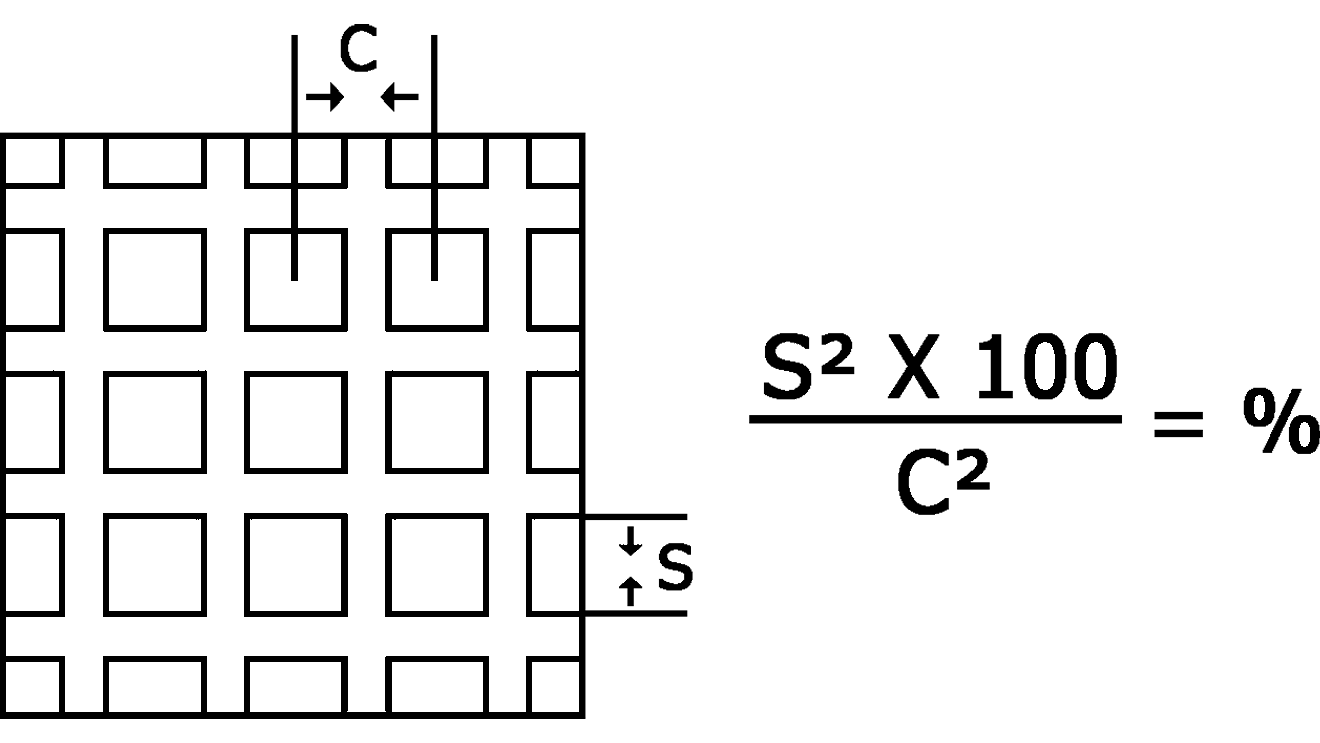

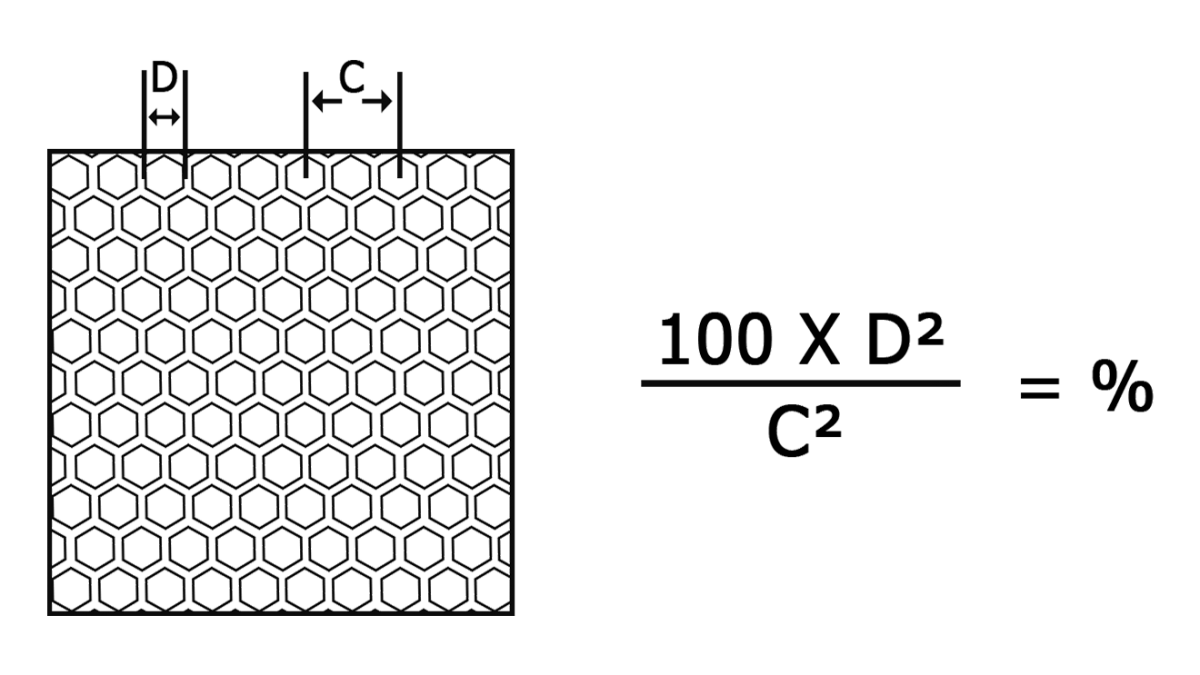

- Open Percent Formulas

Perforation Material

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Galvanized Steel Perforated Metal

- Steel Perforated Metal

- Brass Perforated Metal

- Titanium perforated Metal

Perforated Metal Applications

- Filters And Strainers

- Perforated Screen Plates

- Protective Cover For Equipment

- Anti-Skid Perforated Sheet

- Agricultural Equipment

- Pharmaceutical Component Parts

- Gutter Guard Mesh

- Balustrade Infill Panels

- Perforated wall panels

- Perforated Metal Ceilings

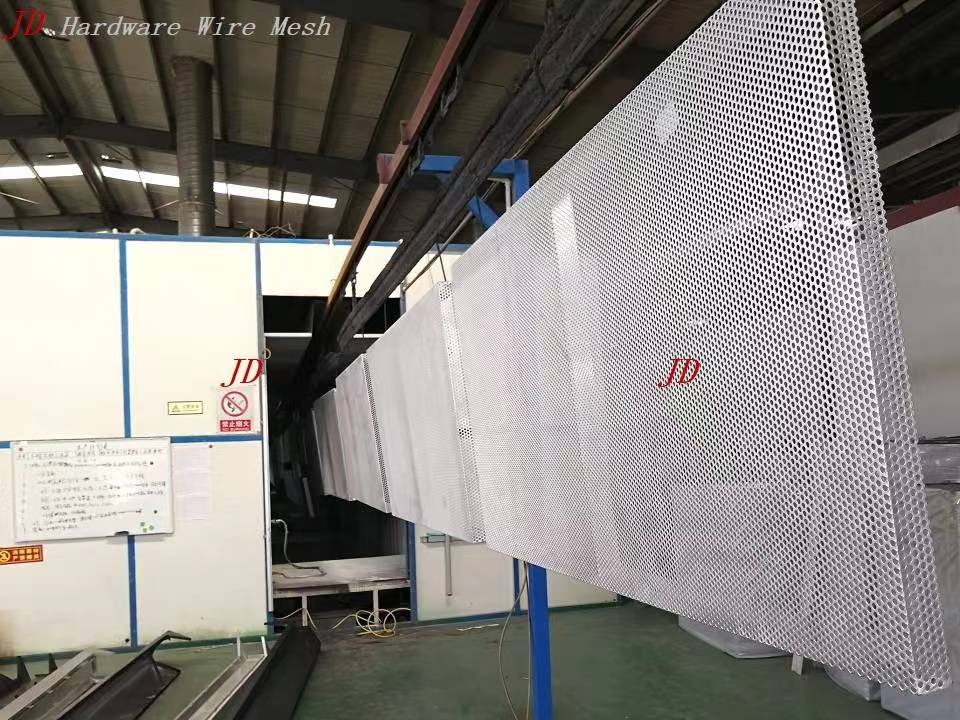

- Perforated Metal Facade

- Aluminum Expanded Facade Panel

Filters And Strainers

Our range of perforated metal, expanded metal and woven wire mesh can be used for all types of filtration purposes. We can even produce filters and strainers fabricated to your own specification, using our range of woven wire mesh as the filter medium, and welding or soldering it to your specific requirements.

With decades of experience, we’re able to offer our technical expertise, helping our customers select the best solution for their filtration and industrial processing needs. Whether that means sourcing the most suitable material to increase flow rates, reduce pressure/vibration or improve structural properties. Over the years we’ve supplied to a variety of industries including: healthcare & pharmaceutical, petrochemical and waste water, to name but a few.

Technical Details:

Opening shape: round, square, slot, etc.

Hole sizes: 0.5 mm to 10mm (other hole sizes are alsoavailable)

Popular thicknesses: 0.4 to 3mm (other thicknesses alsoavailable)

Layers: single layer or multiple layers.

Edge processing: with wrapping edge or metal flange.

Filter precision: 2-2000 µm.

Popular materials: stainless steel, carbon steel, aluminum, copper, galvanized steel sheet, etc.

Features:

High porosity and excellent permeability.

Corrosion resistance and high temperature resistance.

Accurate filtration precision.

Easy processing and installing.

Easy forming, painting, polishing, welding and cleaning.

Firm structure and different hole patterns.

Applications:

Perforated metal filter is widely used in petroleum, chemistry, metallurgy, machine, medicine, automobile industries for distillation, absorption, evaporation and filtration processes, so as to eliminate the impurity and foam mixed in the gas and liquid.

Filtration of air: air filters, vacuum filters, filtration of corrosive gases, cage ventilation, etc.

Filtration of liquid: ceramics polluted water cleaning, beverage, disposal of sewage water, filtration of corrosive liquids, beer brewing filter, etc.

Filtration of solid: glass, coal, food processing industry, cosmetics, fluidised beds, etc.

Filtration of oil: oil refining, hydraulic oil, oilfield pipelines, etc.

Filtration of other fields: textile industry, insulation industry, automotive industry, chemical industry, metallurgy, pharmacy, electronic field, etc.