Hole Pattern

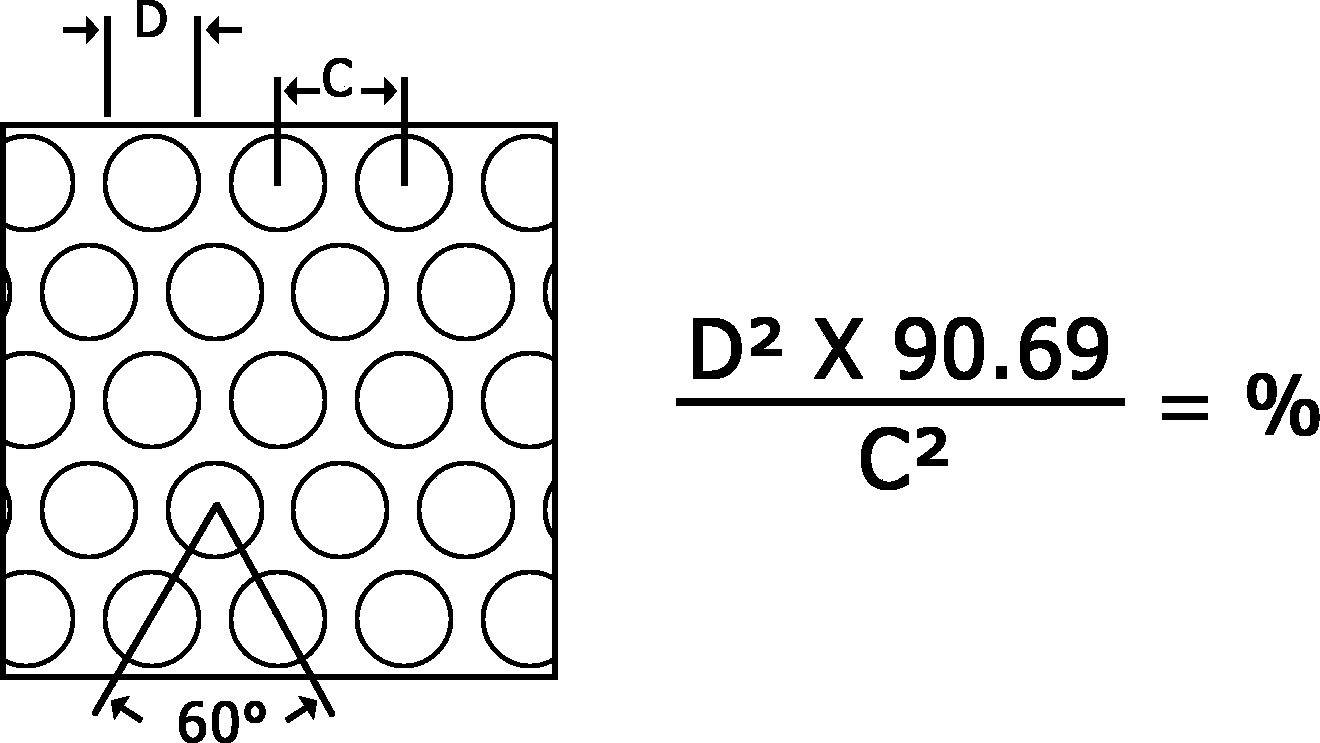

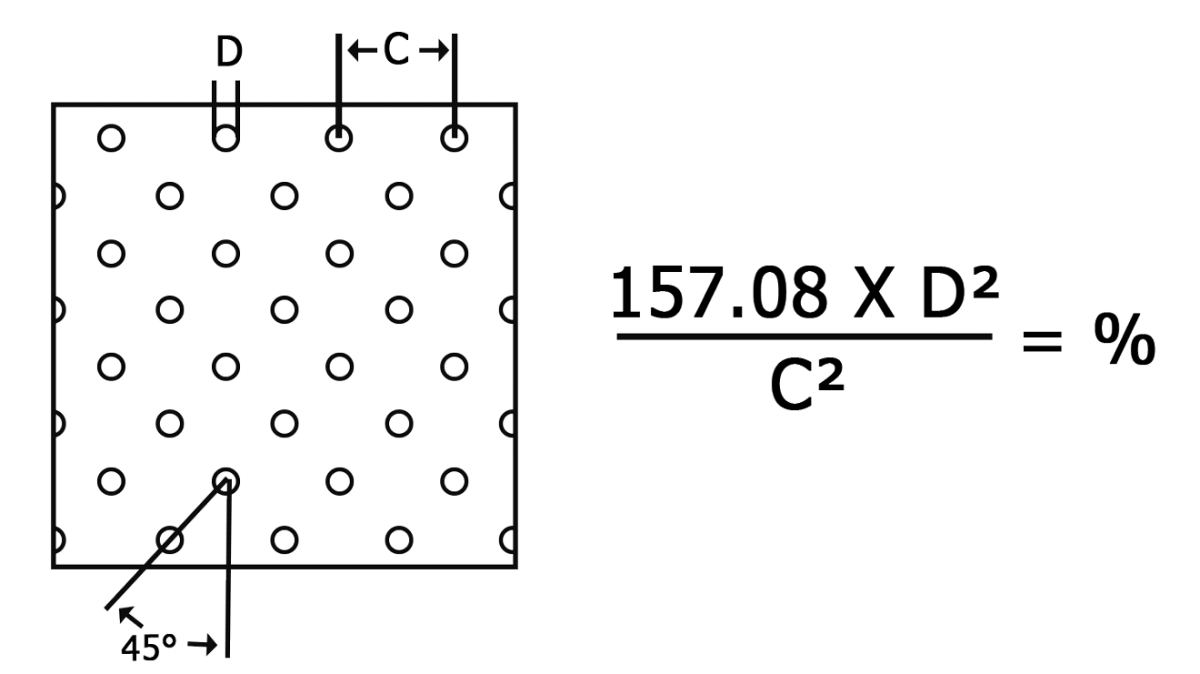

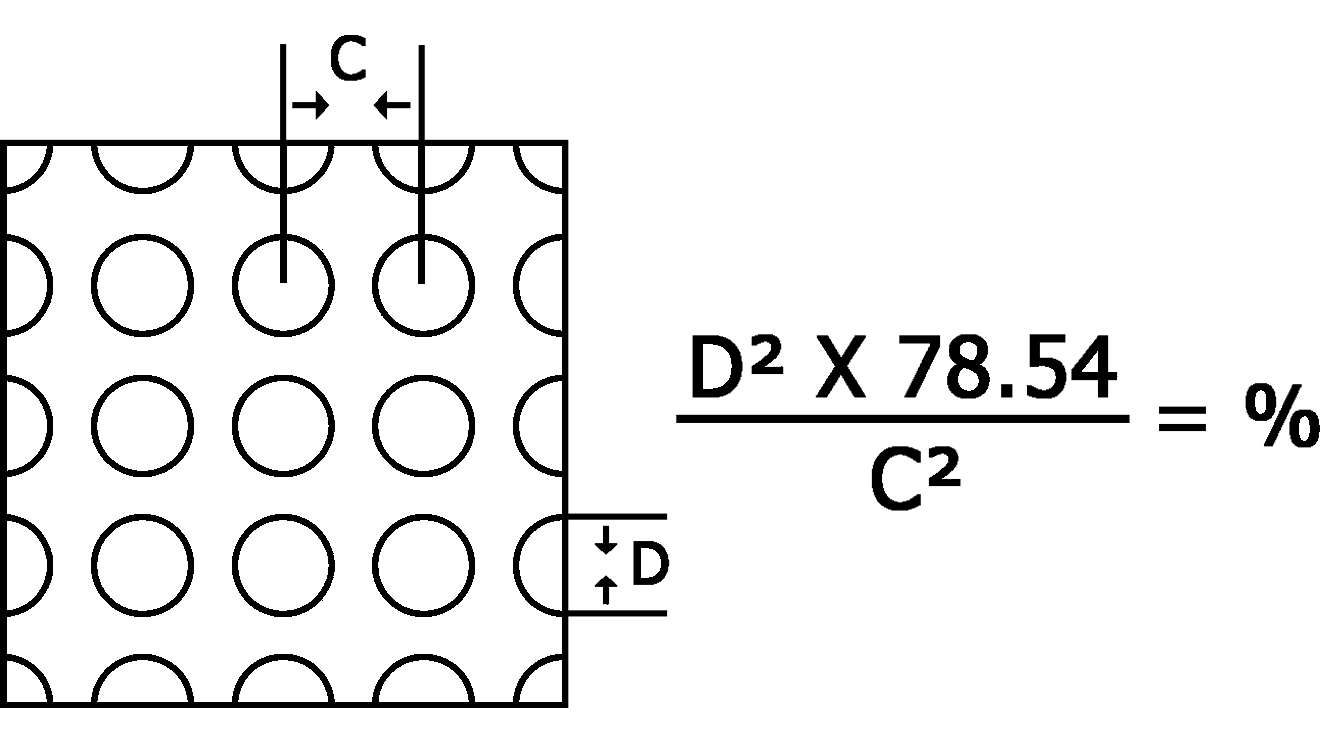

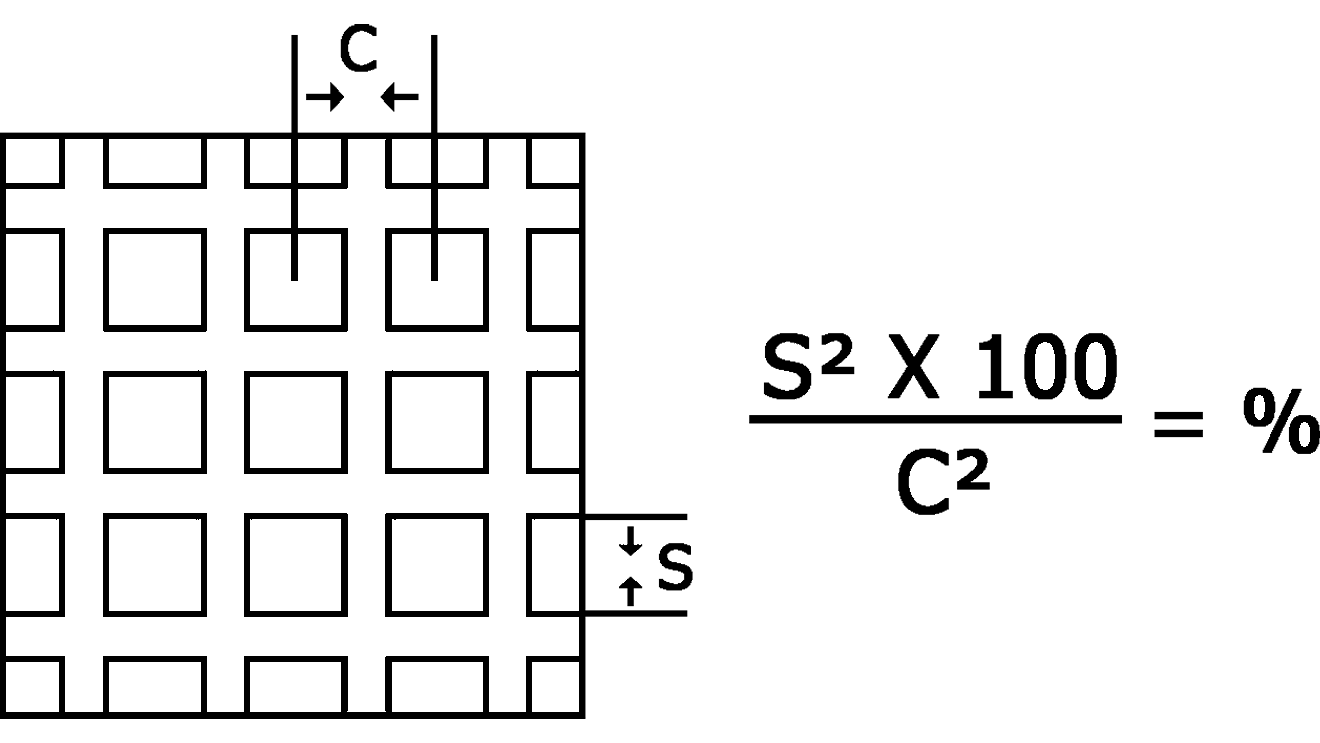

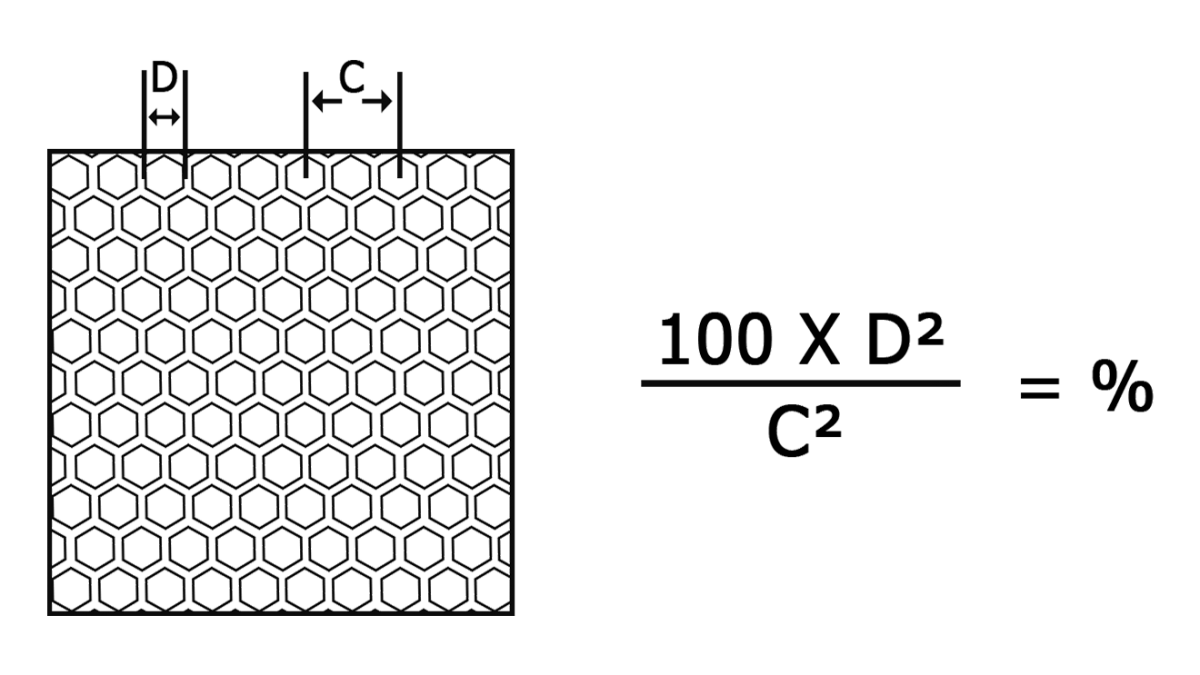

- Round Hole Perforated Metal

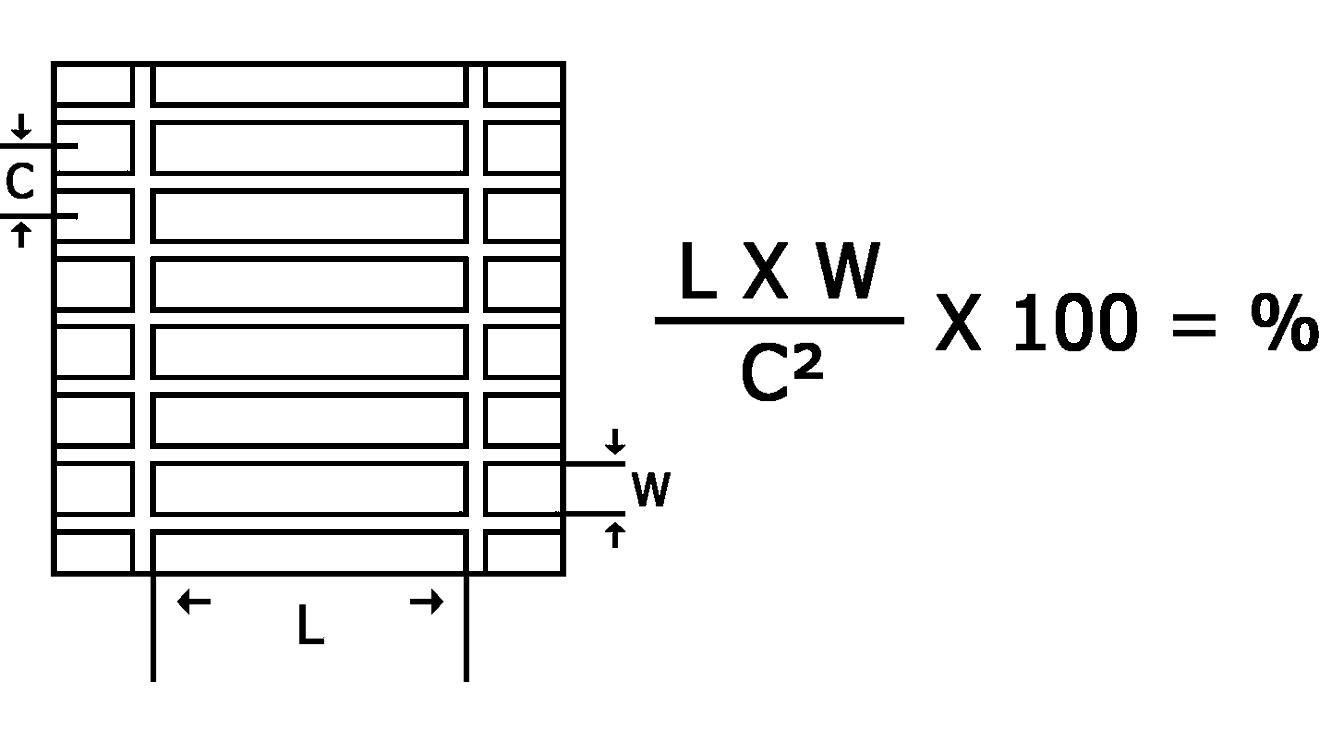

- Square Hole Perforated Metal

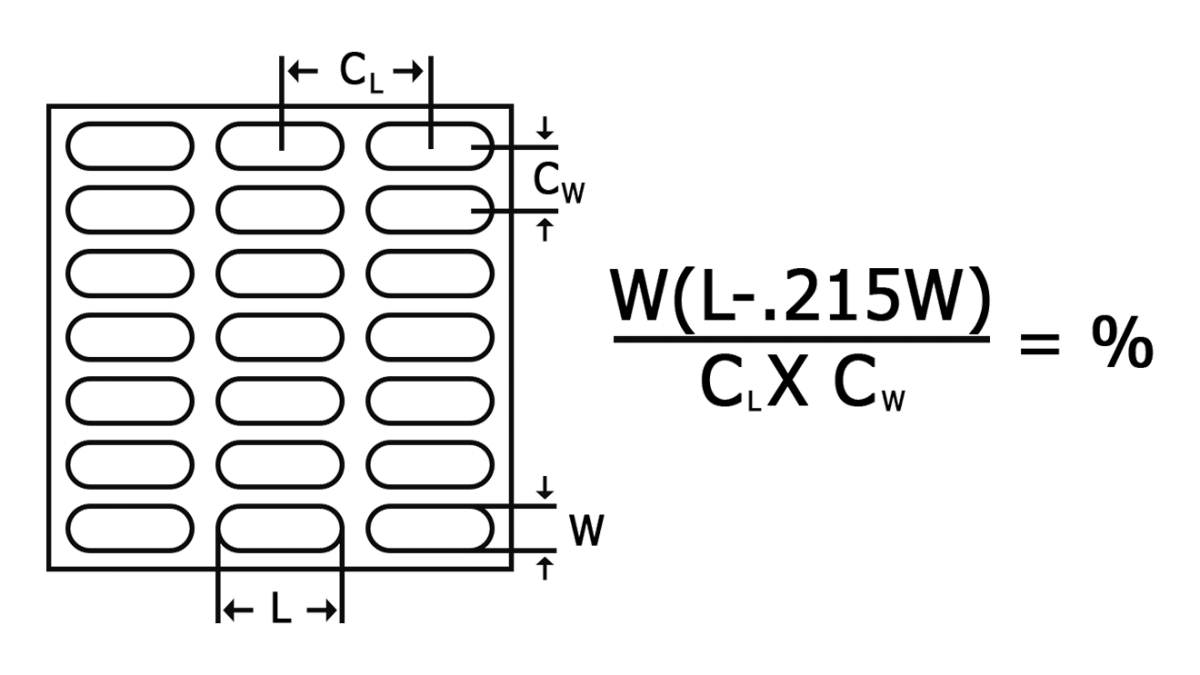

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Expanded Metal Mesh

- Open Percent Formulas

Perforation Material

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Galvanized Steel Perforated Metal

- Steel Perforated Metal

- Brass Perforated Metal

- Titanium perforated Metal

Perforated Filter Series

- Perforated Filter Disc

- Stainless Steel Perforated Tube

- Aluminum Perforated Tube

- Spiral Welded Perforated Tube

- Spiral Lock Seam Tube

- Conical Strainer

- Basket Strainer

- Perforated Filter Elements

Perforated Metal Applications

- Filters And Strainers

- Perforated Screen Plates

- Protective Cover For Equipment

- Balustrade Infill Panels

- Perforated wall panels

- Perforated Metal Ceilings

- Perforated Metal Facade

- Aluminum Perforated Facade Panel

- Aluminum Expanded Facade Panel

- Anti-Skid Perforated Sheet

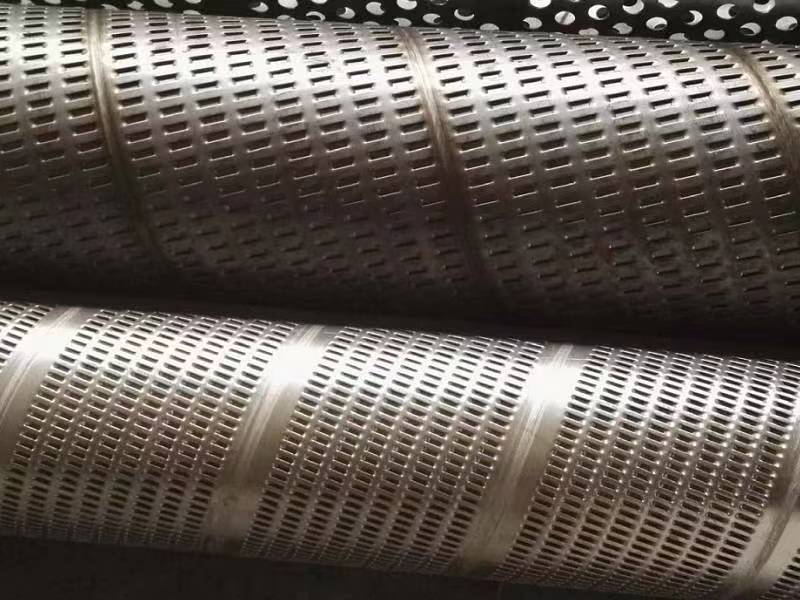

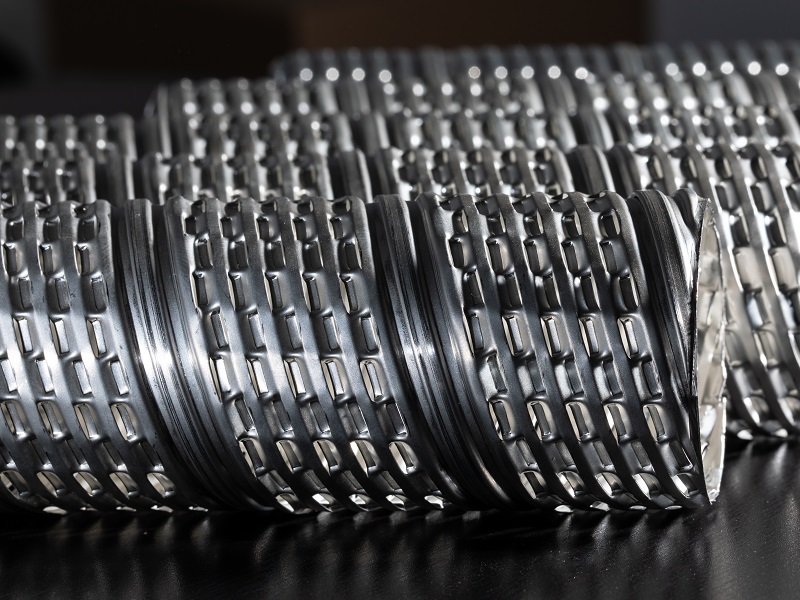

Spiral Welded Perforated Tube

Spiral Welded Perforated Tube Superior for Its Precision Spiral Welding

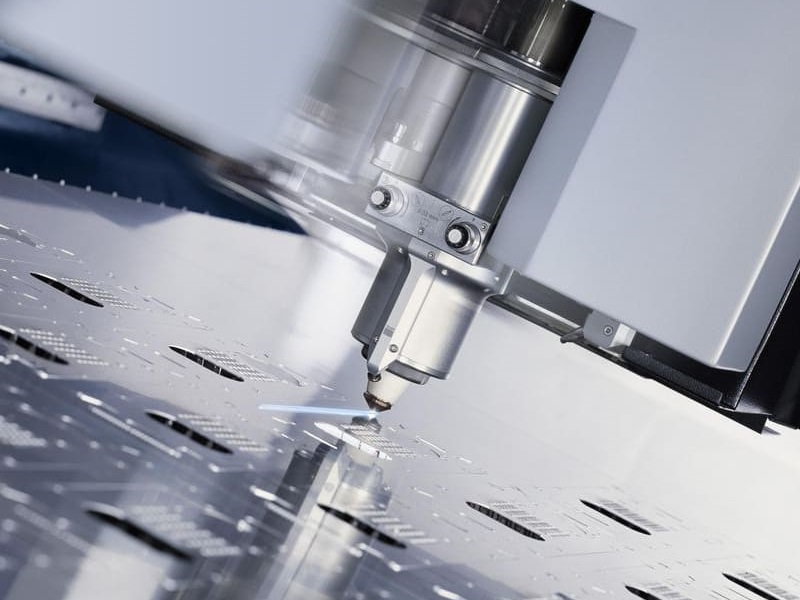

Spiral welded perforated pipe is helically formed and automatically welded of continuous sheets of perforated metal based on high precision and high quality of welding. Compared with straight welded tube, spiral welded tubing is approximately 15% stronger. Spiral metal tube does great job in holding high pressure and high impacts.

Spiral welded tubing has been processed by centerless grinding, plating, sand blasting, deburring and buffing. These finishes will make subsequent operations smooth and cost-efficient.

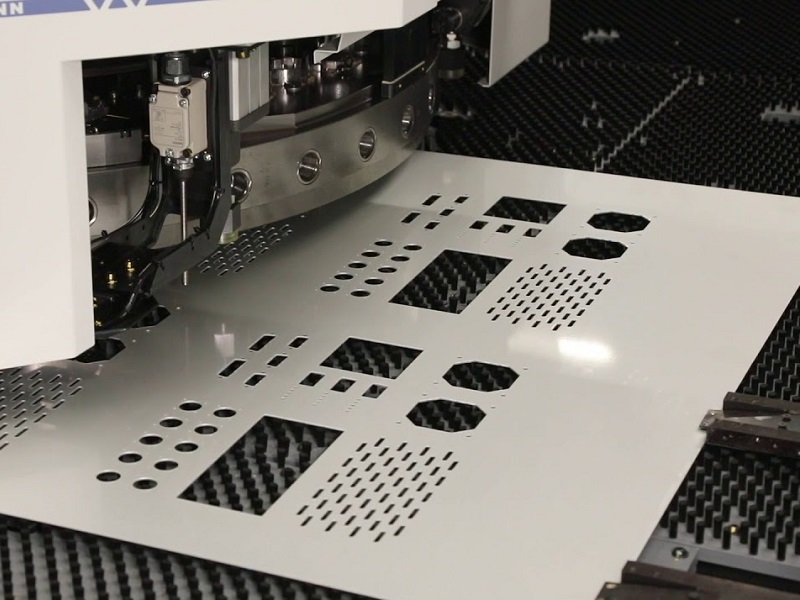

Specifications:

Materials: Mild carbon steel, stainless steel.

Thickness: 0.7mm - 3.0mm.

Hole diameter: 1mm-10mm.

Open area: up to 65%.

Hole Shape: round, slot and square.

Holes Distribution: straight line, staggered.

Outside diameter: 25mm to 300mm.

Length: as required.

Note: Hole size and distribution can be bespoke according to special order.

Features:

Welded evenly.

Light weight, high strength, not so easy to deform, durable.

Exact dimensions, high permeability, larger area flow.

Excellent corrosion, abrasion, heat and resistance.

Little maintenance, longer service life.

Reusable after cleaning.

Applications:

It is often found in pulp mills, chemical processing and brewing industries.