Hole Pattern

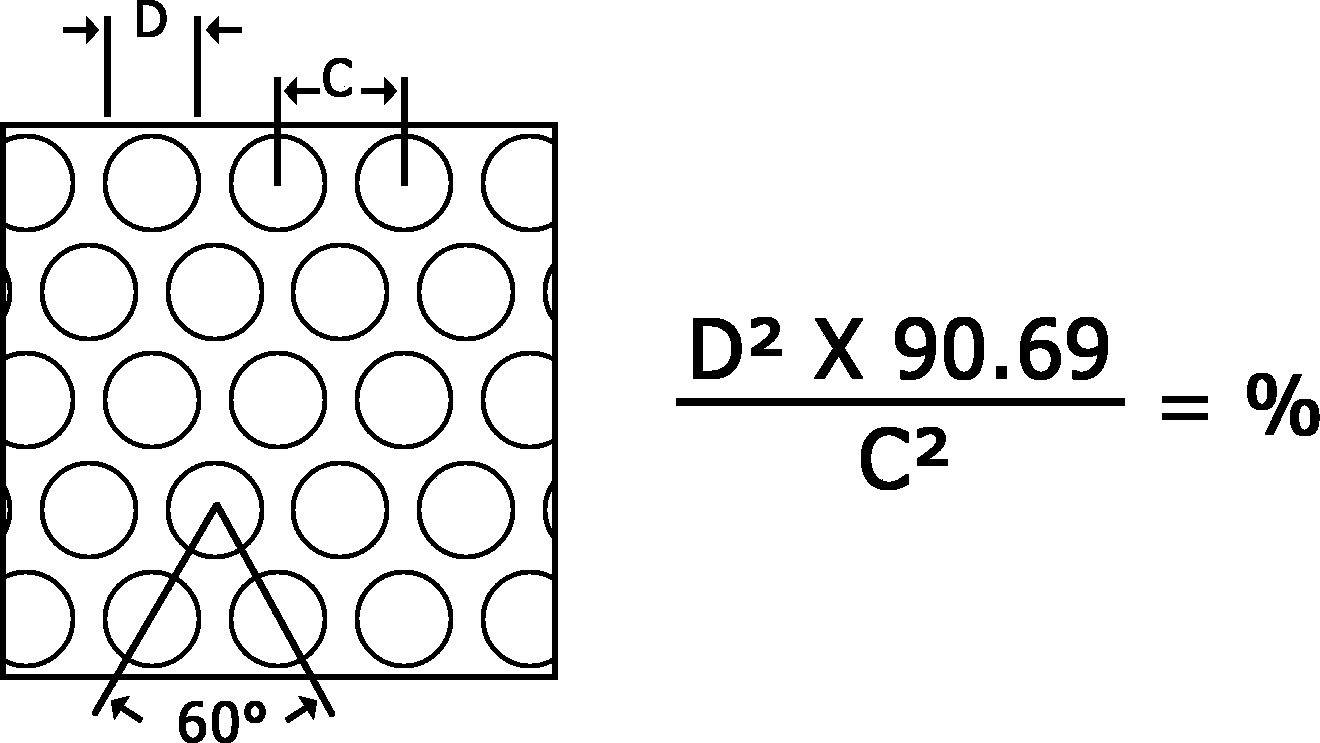

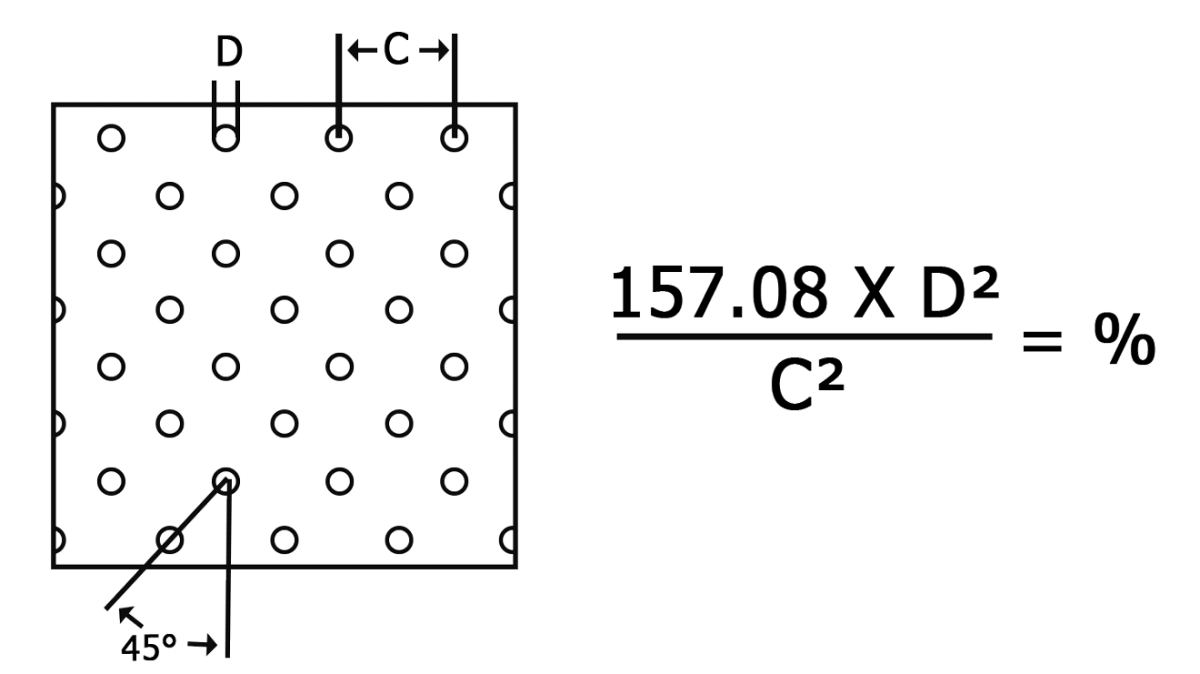

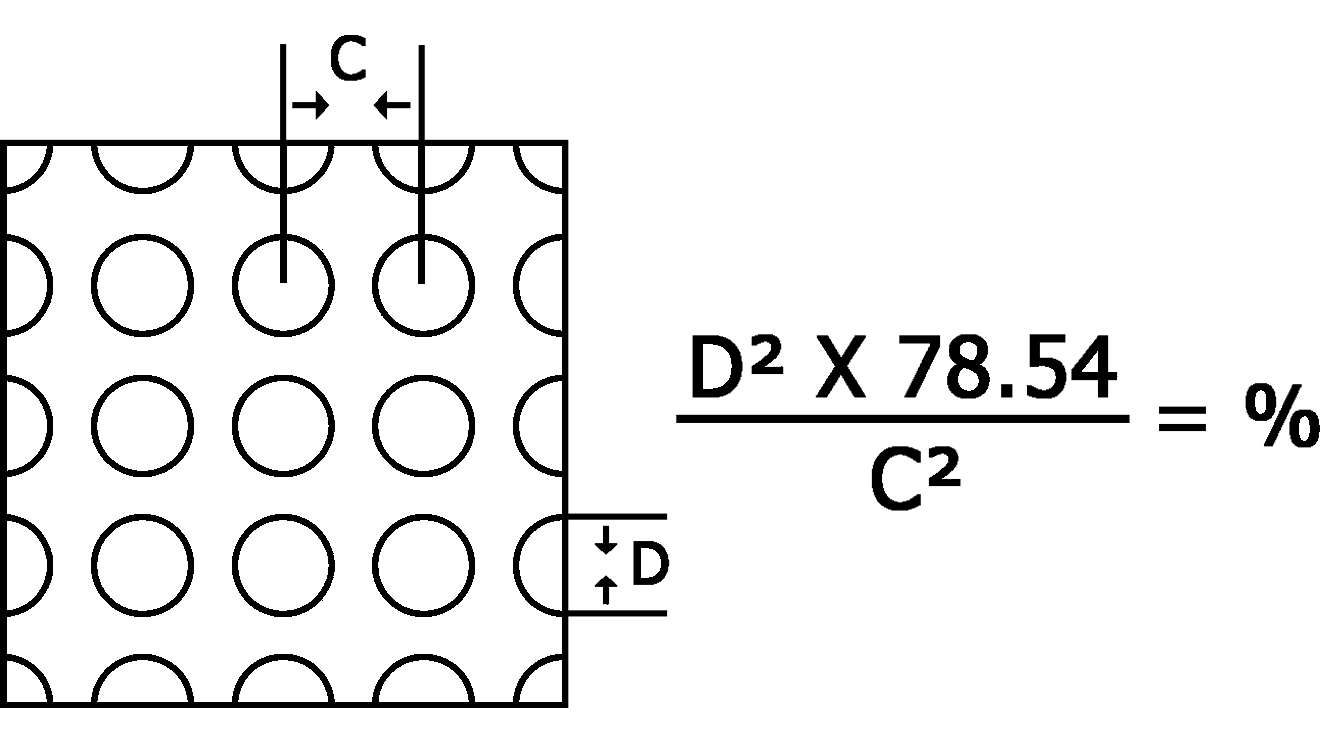

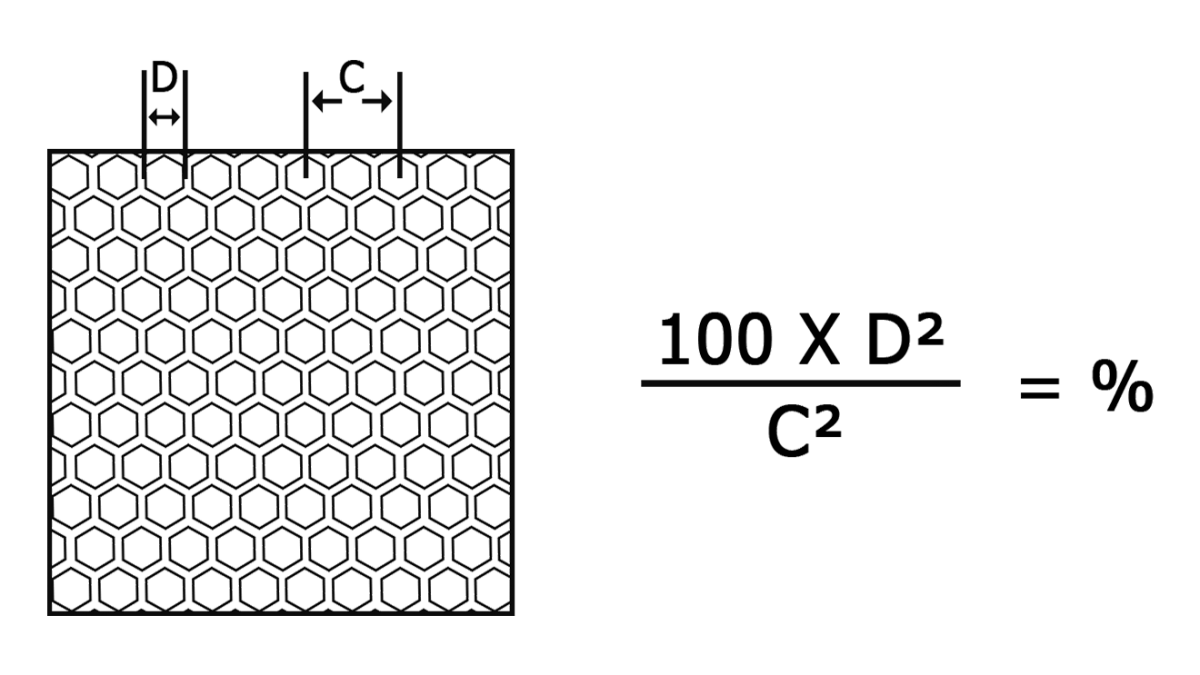

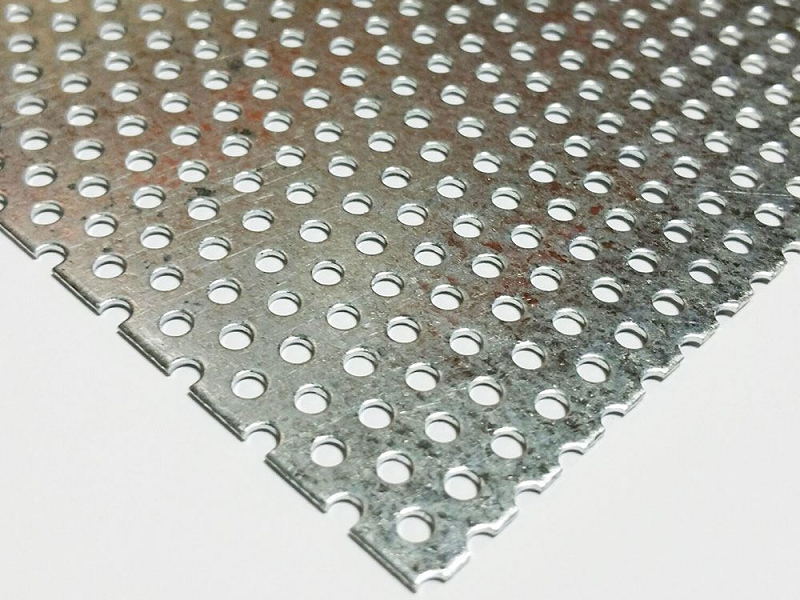

- Round Hole Perforated Metal

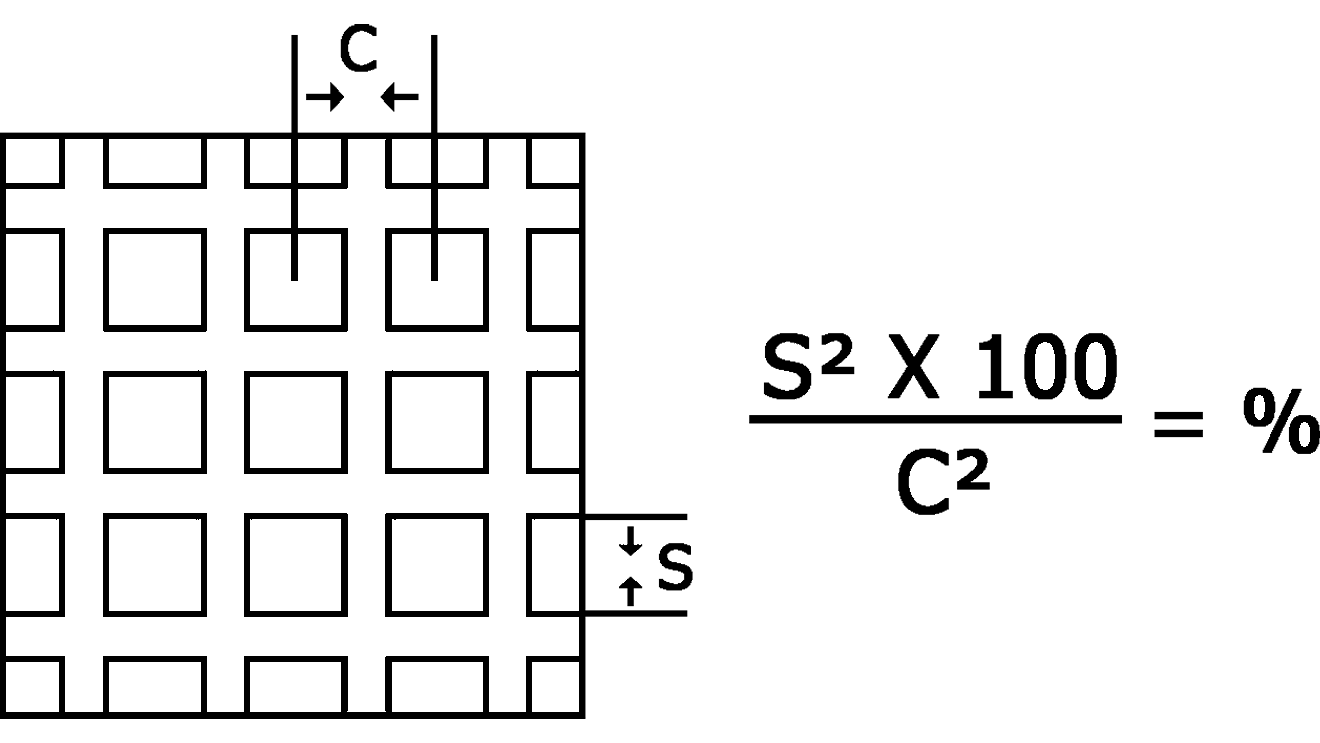

- Square Hole Perforated Metal

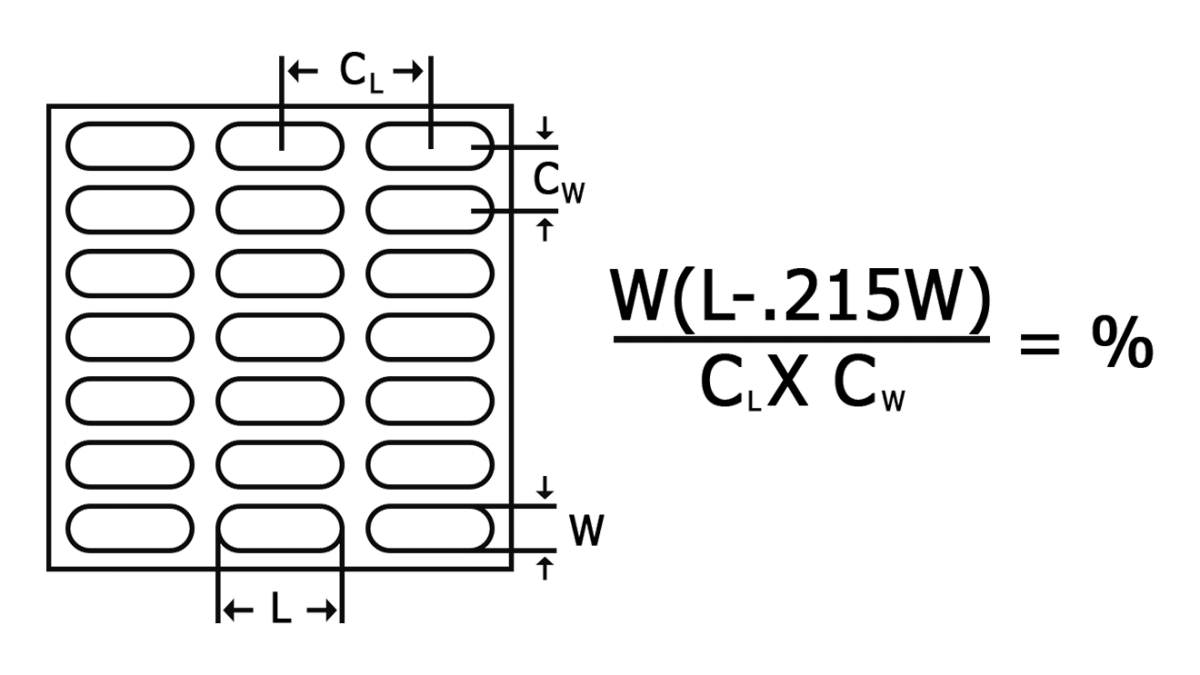

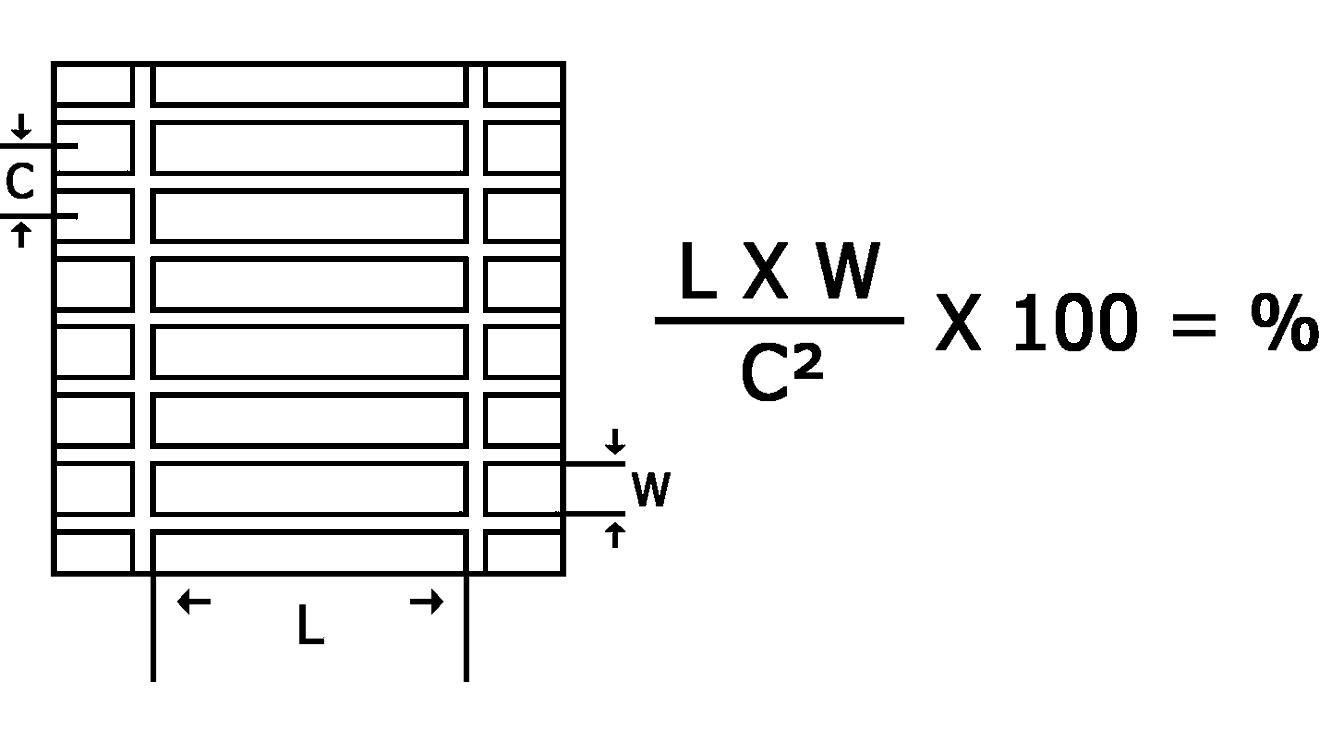

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Open Percent Formulas

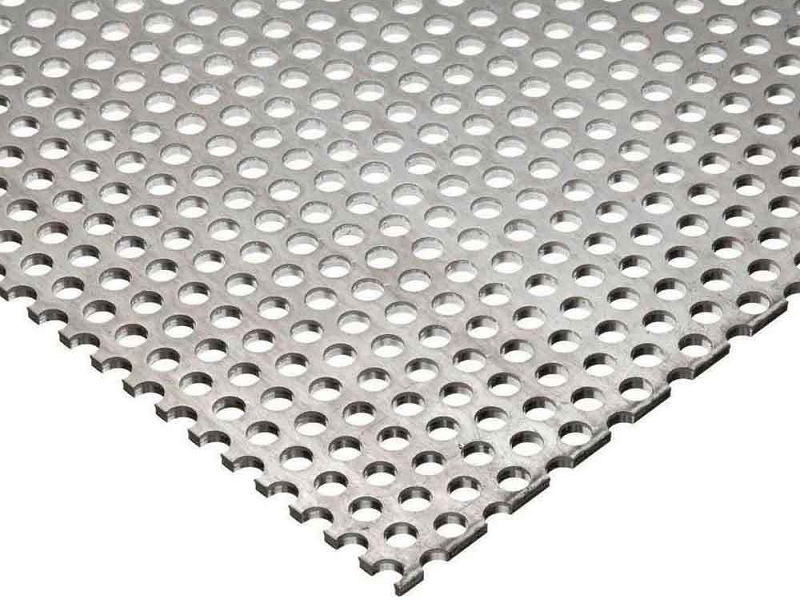

Perforation Material

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Steel Perforated Metal

- Galvanized Steel Perforated Metal

- Brass Perforated Metal

Perforated Metal Applications

- Filters

- Perforated Screen Plates

- Aluminum Exterior Building Facades

- Protective Cover For Rquipment

- Perforated Metal Ceilings

- Perforated Metal Infill Panels

- Anti-Skid Perforated Sheet

- Perforated Metal Noise Barrier

410 Stainless Steel

Principal Design Features: 410 is the basic martensitic stainless which will attain high mechanical properties after heat treatment. It has good impact strength, corrosion and scaling resistance up to 1200 F (649 C).

Applications: Cutlery, steam and gas turbine blades and buckets, bushings, valve components, fasteners, screens and kitchen utensils.

Machinability: Tough, draggy chips with heavy build-up. While this alloy can be machined in the annealed condition, it tends to perform better in the cold drawn or heat treated condition.

Welding: Most common methods of welding can be successfully employed with this alloy. To reduce the chance of cracking, it is advisable to preheat the workpiece to 350-400 F (177-204 C). Post-weld annealing is recommended to reattain maximum ductility. Filler metal, when required, should be AWS E/ER410.

410 Chemistry Data

| Carbon | 0.15 max |

| Chromium | 11.5-13.5 |

| Iron | Balance |

| Manganese | 1 max |

| Phosphorus | 0.04 max |

| Silicon | 1 max |

| Sulphur | 0.03 max |

410 Physical Data

| Density (lb / cu. in.) | 0.28 |

| Specific Gravity | 7.7 |

| Specific Heat (Btu/lb/Deg F - [32-212 Deg F]) | 0.11 |

| Electrical Resistivity (microhm-cm (at 68 Deg F)) | 342 |

| Melting Point (Deg F) | 2790 |

| Modulus of Elasticity Tension | 29 |