Hole Pattern

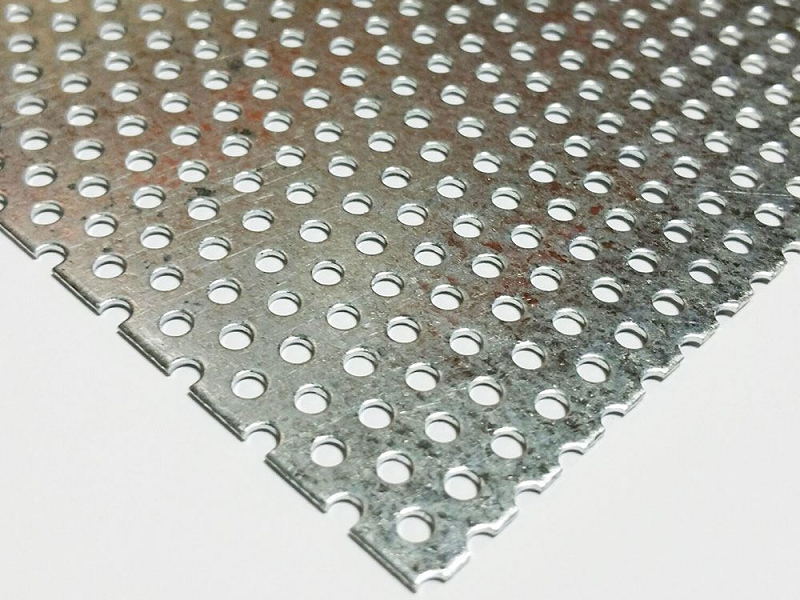

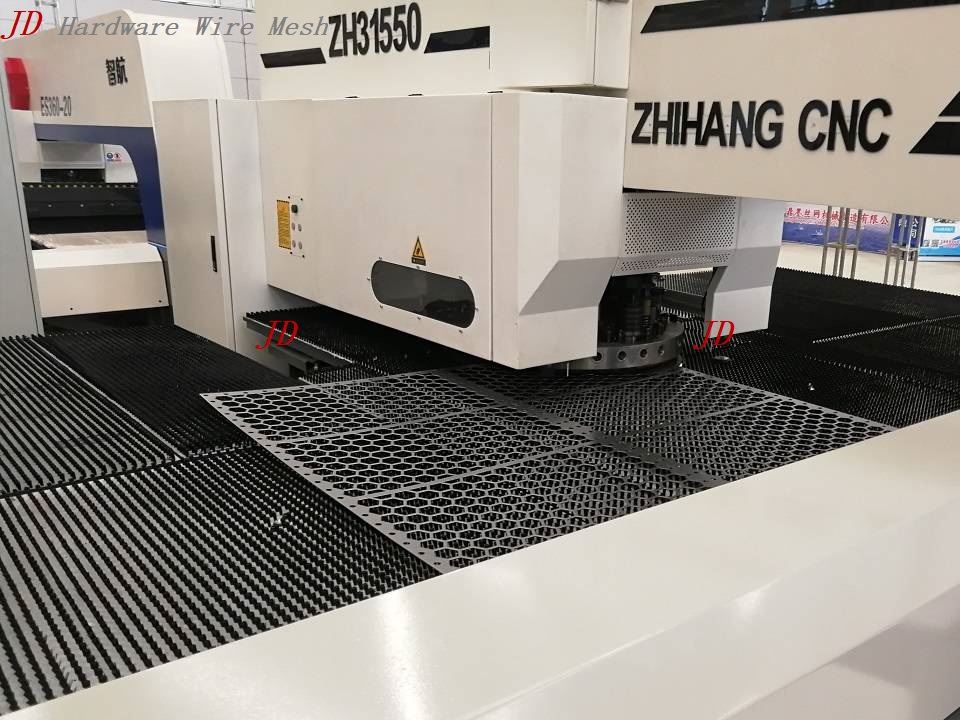

- Round Hole Perforated Metal

- Square Hole Perforated Metal

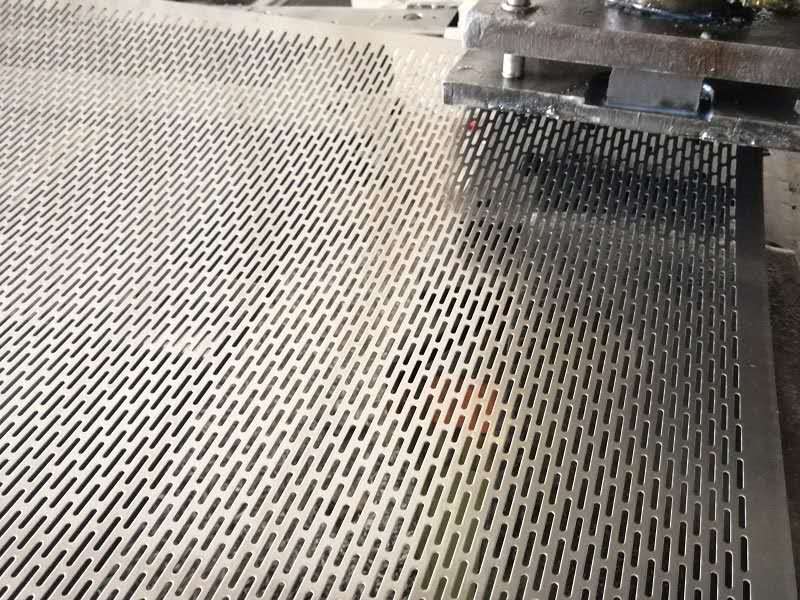

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Expanded Metal Mesh

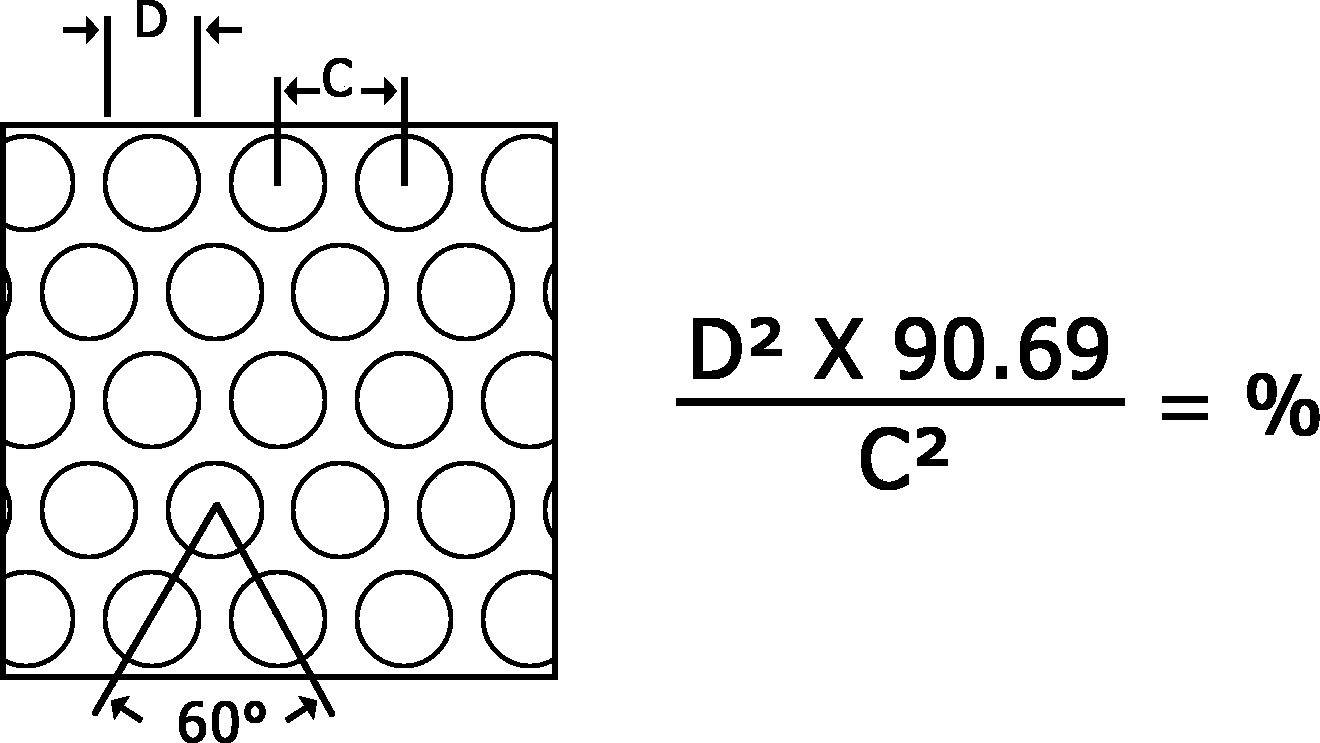

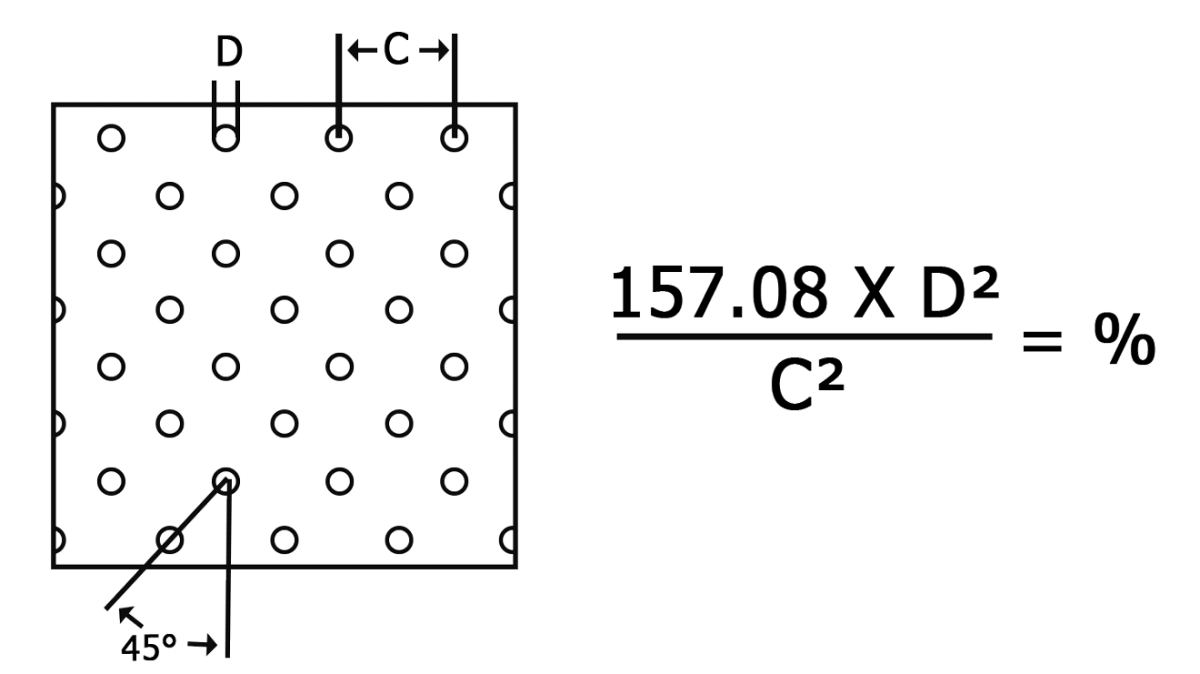

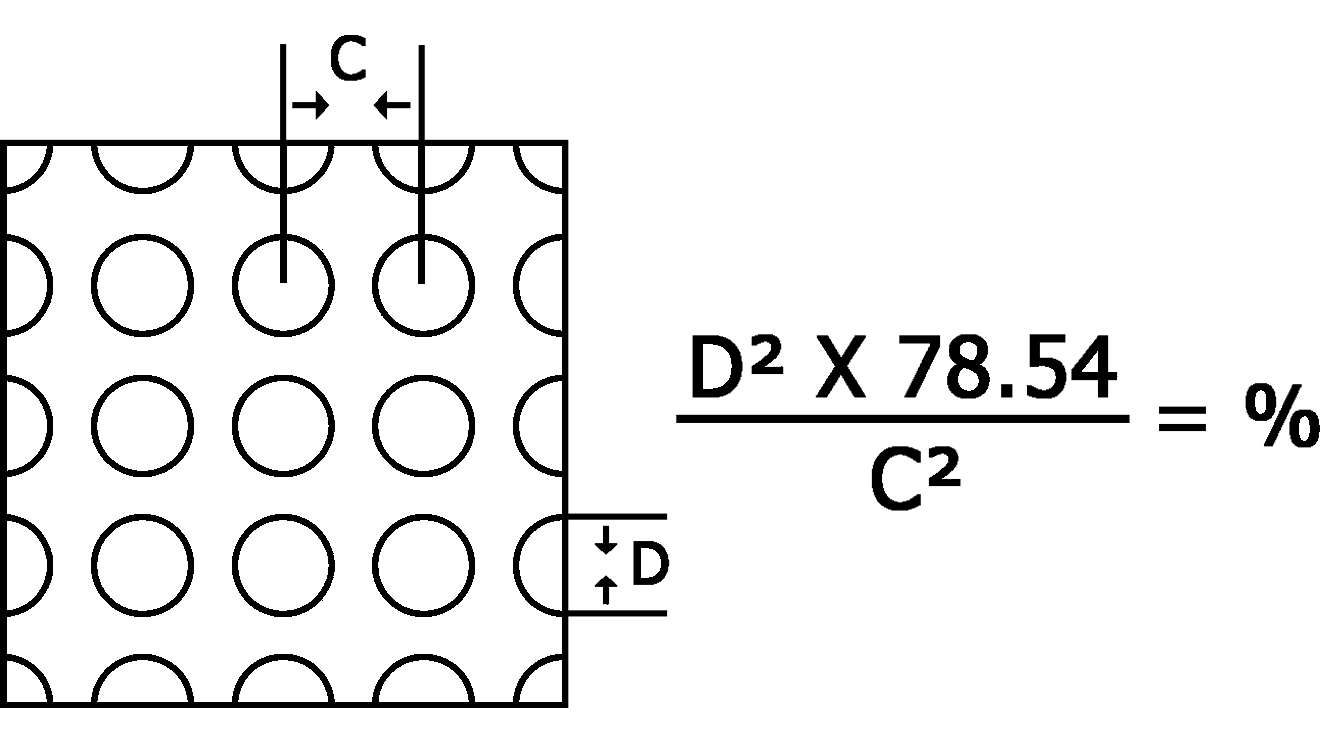

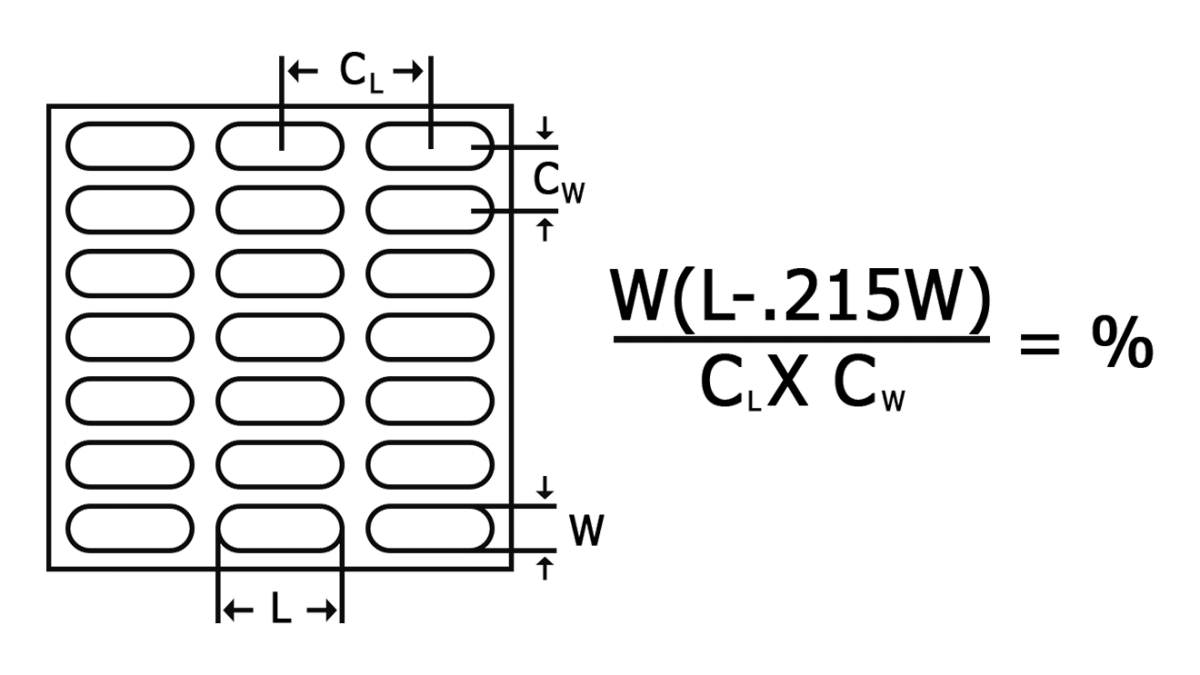

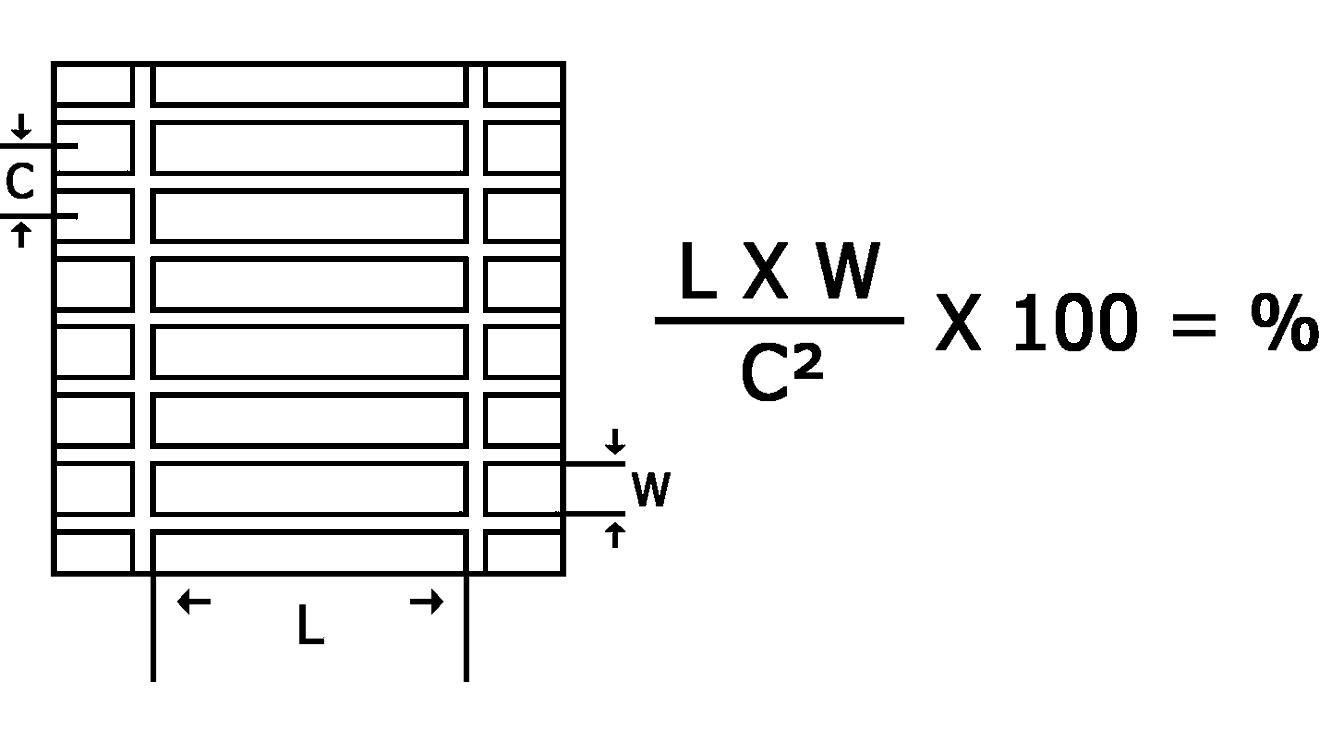

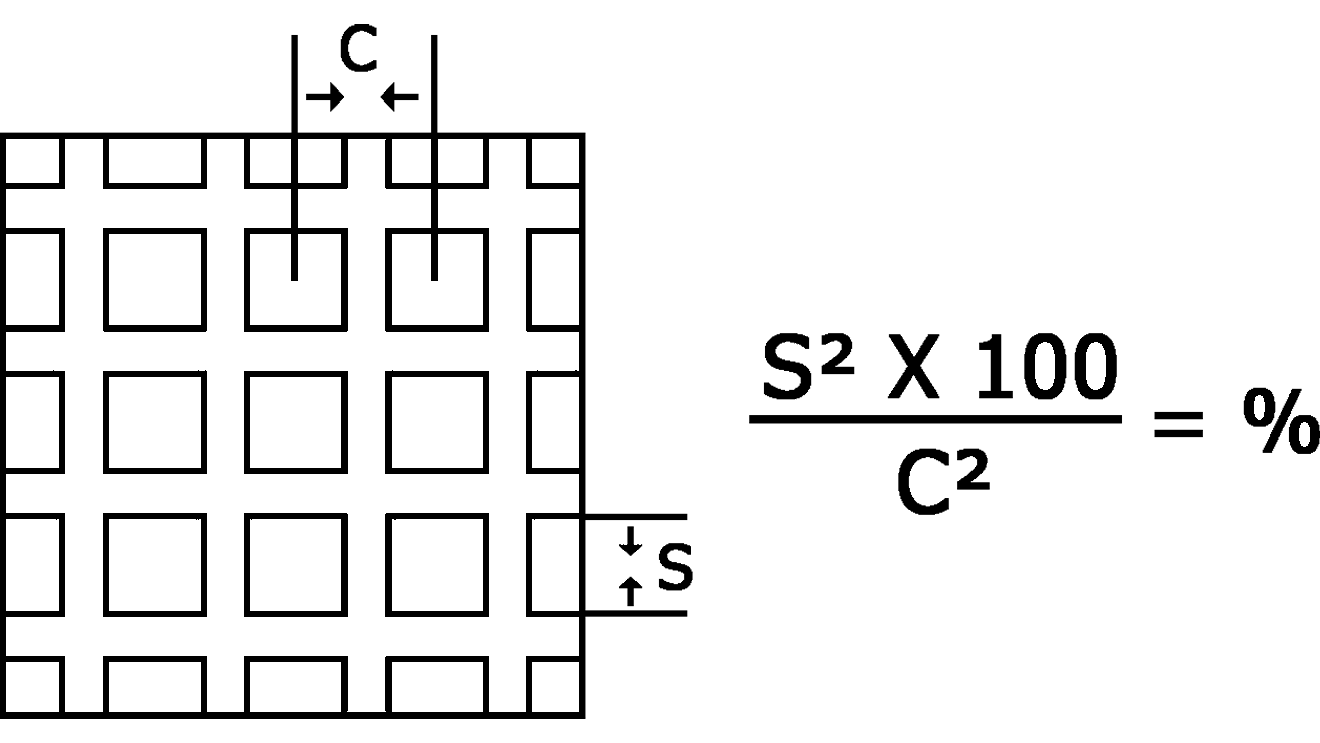

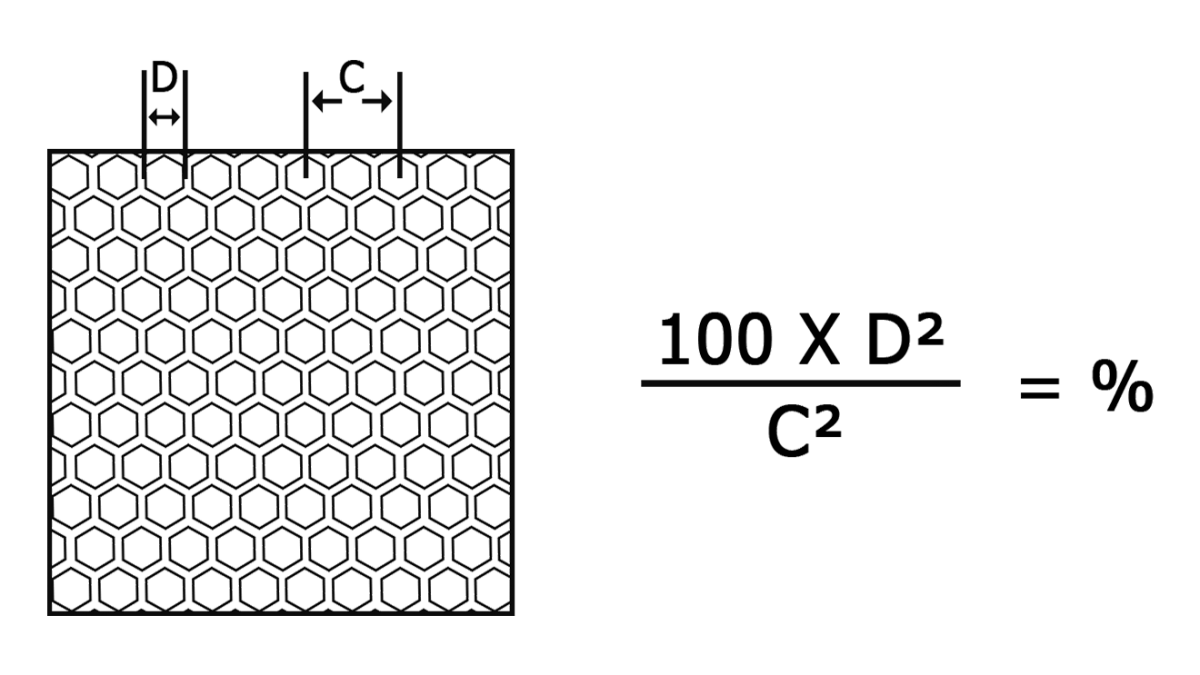

- Open Percent Formulas

Perforation Material

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Galvanized Steel Perforated Metal

- Steel Perforated Metal

- Brass Perforated Metal

- Titanium perforated Metal

Perforated Metal Applications

- Filters And Strainers

- Perforated Screen Plates

- Protective Cover For Equipment

- Anti-Skid Perforated Sheet

- Agricultural Equipment

- Pharmaceutical Component Parts

- Gutter Guard Mesh

- Balustrade Infill Panels

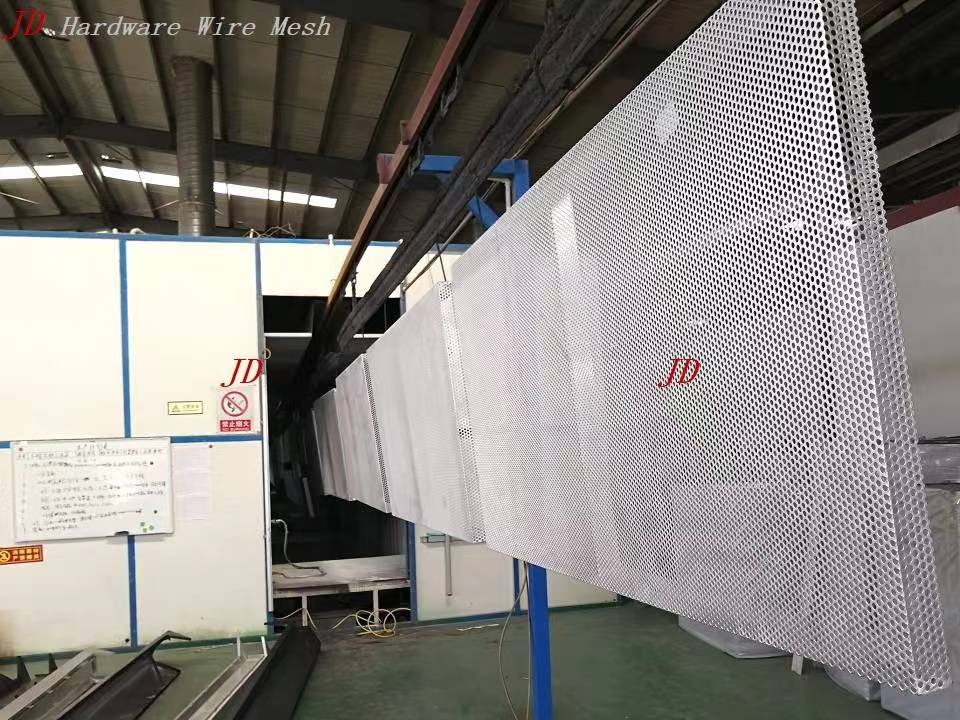

- Perforated wall panels

- Perforated Metal Ceilings

- Perforated Metal Facade

- Aluminum Expanded Facade Panel

Stainless Steel Perforated Metal

Stainless steel, alsoknown ascorrosion-resistant steel, is aniron-based steel alloy, containingminimum 11%chromium. Chromium present in itprevents it from getting corroded,by forming aself-healing film of chromiumoxide on the surface of stainless steel.Apartfrom being corrosion resistant,it is also known for its qualities ofhighductility, weldability and cryogenictoughness. Stainless steel is gradedbytaking into consideration theenvironment that it will be assigned to.Thegrading system that is mostcommonly used for grading stainless steel is theSAESteel Grades, designatedby the Society of Automotive Engineers (SAE), andtheUNS grades.

Material: 304, 304L, 309, 310, 316, 316L, 321, 347, 410, 430, 904L etc. Other standards materials are alsoavailable as your requirements.

Holeshape: round, square & rectangular, slot, hexagon, oblong, diamond andother decorative shapes.

Different Grades of StainlessSteel

Stainless steel grades are iron alloysthat contain more than 10.5% ofchromium. Other alloys are added to stainlesssteel to amplify its properties.The grading is based on the metallurgicalstructure and nature of stainlesssteel. The grades of stainless steel arecategorized into different families onthe basis of the properties that theydisplay.

Austenitic Stainless Steel – Series100-300

The family of austenitic stainless steelare the alloys that contain 16%chromium and 6% nickel. Other elements such ascopper, titanium or molybdenumcan be added to amplify its properties. Thecombination of all these elementsmake it suitable for use in the work involvinghigh corrosion resistance andhigh temperature resistance. It is alsoeffectively resistant to atmosphericcorrosion and corrosion by organic,oxidizing and mineral acids. It displaysproperties like high ductility,cryogenic toughness and weldability. This makesit possible to fabricateaustenitic stainless steel by punching, spinning,welding, frilling, bending,etc. It is also non-magnetic. The important austeniticgrades are the 200 series(chrome-manganese series) and the 300 series(chrome-nickel series). The 300series is the largest manufactured stainlesssteel type in the world. Austeniticstainless steel is mainly used in themanufacture of cutlery, kitchen appliancesand consumer durables and also forthe construction purposes.

Ferritic Stainless Steel

The family of ferritic stainless steelalloys has chromium content ofmore than 10.5% and a low carbon content. Theyare plain chromium grades,display magnetic properties and cannot be hardened.They are not suitable forfabrication and are moderately resistant to corrosion.They can be polished andare used for the manufacture of automotive exhausts andsometimes for weldingapplications.

Duplex Stainless Steel – 2304 and 2205

The family of duplex stainless steelalloys possesses a high chromiumcontent of 18% to 28% and a moderate nickelcontent of 1% to 8%. They are acombination of austenitic and ferritic stainlesssteel alloy structures andthey may also contain molybdenum, copper, manganeseor tungsten. They displayhigh yield strength and resistance to stresscorrosion, cracking and ionattack. The are used in the paper and pulp,petrochemical and marineapplication industries and in the desalination plants.

Martensitic Stainless Steel– Series 400

The family of martensitic stainlesssteel are alloys having 11.5% to18%chromium and high carbon content of 0.1% to2%. It can be easily hardened bysubjecting it to heat, and is highly resistantto abrasion, but it displaysless resistance to corrosion compared to otheralloys of stainless steel. Itdisplays magnetic properties and is used in themanufacture of surgicalinstruments, valves, knife blades, etc.

Please contact us todayto learn moreabout how we can provide a high quality stainless steel solutionfor yourspecific needs.

Stainless Steel Grades – Chemical Composition

| Alloy # | CR | Ni | C | Mn.Max. | Si-Max. | P.Max. | S.Max. | Other Elements |

| 304 | 18.0/20.0 | 8.0/11.0 | 0.08 Max. | 2 | 1 | 0.04 | 0.03 | .......... |

| 304L | 18.0/20.0 | 8.0/11.0 | 0.03 Max. | 2 | 1 | 0.04 | 0.03 | .......... |

| 305 | 17.0/19.0 | 10.0/13.0 | 0.12 Max. | 2 | 1 | 0.04 | 0.03 | .......... |

| 308 | 19.0/21.0 | 10.0/12.0 | 0.08 Max. | 2 | 1 | 0.04 | 0.03 | .......... |

| 309 | 22.0/24.0 | 12.0/15.0 | 0.20 Max. | 2 | 1 | 0.04 | 0.03 | .......... |

| 310 | 24.0/26.0 | 19.0/22.0 | 0.25 Max. | 2 | 1 | 0.04 | 0.03 | .......... |

| 314 | 23.0/26.0 | 19.0/22.0 | 0.25 Max. | 2 | 1 | 0.04 | 0.03 | .......... |

| 316 | 16.0/18.0 | 10.0/14.0 | 0.08 Max. | 2 | 1 | 0.04 | 0.03 | Mo. 2.00/3.00 |

| 316L | 16.0/18.0 | 10.0/14.0 | 0.03 Max. | 2 | 1 | 0.04 | 0.03 | Mo. 2.00/3.00 |

| 317 | 18.0/20.0 | 11.0/15.0 | 0.08 Max. | 2 | 1 | 0.04 | 0.03 | Mo. 3.00/4.00 |

| 321 | 17.0/19.0 | 9.0/12.0 | 0.08 Max. | 2 | 1 | 0.04 | 0.03 | Ti 5xC Min. |

| 330 | 14.0/16.0 | 35.0/37.0 | 0.25 Max. | .... | .... | .... | .... | .......... |

| 347 | 17.0/19.0 | 9.0/13.0 | 0.08 Max. | 2 | 1 | 0.04 | 0.03 | Cb+Ta 10xC Min. |

| 410 | 11.5/13.5 | .... | 0.15 | 1 | 1 | 0.04 | 0.03 | .......... |

| 430 | 14.0/18.0 | .... | 0.12 Max. | 1 | 1 | 0.04 | 0.03 | ........ |

Table: Stainless steel grades and their international equivalents

| USA | France | Germany | Germany | Italy | Japan | Russia | UK | European Union |

| AISI | AFNOR | DIN 17006 | W.N. 17007 | UNI | JIS | GOST | BSI | EURO NORM |

| 304 | Z 6 CN 18-09 | X 5 CrNi 18 10 X 5 CrNi 18 12 | 1.4301 1.4303 | X 5 CrNi 1810 | SUS 304 | 08KH18N10 06KH18N11 | 304S15 304S16 | X 6 CrNi 18 10 |

| 304 N | X 5 CrNiN 1810 | SUS 304N1 | ||||||

| 304 H | X 8 CrNi 1910 | SUS F 304H | ||||||

| 304 L | Z 2 CN 18-10 | X 2 CrNi 18 11 | 1.4306 | X 2 CrNi 1911 | SUS 304L | 03KH18N11 | 304S11 | X 3 CrNi 18 10 |

| Z 2 CN 18-10-Az | X 2 CrNiN 18 10 | 1.4311 | X 2 CrNiN 1811 | SUS 304LN | ||||

| Z 6 CNU 18-10 | SUS XM7 | X 6 CrNiCu 18 10 4 Kd | ||||||

| 309 | Z 15 CN 24-13 | X 15 CrNiS 20 12 | 1.4828 | X 16 CrNi 2314 | SUH 309 | 309S24 | X 15 CrNi 23 13 | |

| 309 S | X 6 CrNi 2314 | SUS 309S | 20KH23N18 | X 6 CrNi 22 13 | ||||

| 310 | X 12 CrNi 25 21 | 1.4845 | X 22 CrNi 2520 | SUH 310 | 10KH23N18 | 310S24 | ||

| 310 S | Z 12 CN 25-20 | X 12 CrNi 25 20 | 1.4842 | X 5 CrNi 2520 | SUS 310S | 20KH25N20S2 | X 6 CrNi 25 20 | |

| 314 | Z 12 CNS 25-20 | X 15 CrNiSi 25 20 | 1.4841 | X 16 CrNiSi 2520 | X 15 CrNiSi 25 20 | |||

| 316 | Z 6 CND 17-11 | X 5 CrNiMo 17 12 2 | 1.4401 | X 5 CrNiMo 1712 | SUS 316 | 316S31 | X 6 CrNiMo 17 12 2 | |

| 316 | Z 6 CND 17-12 | X 5 CrNiMo 17 13 3 | 1.4436 | X 5 CrNiMo 1713 | SUS 316 | 316S33 | X 6 CrNiMo 17 13 3 | |

| 316 F | X 12 CrNiMoS 18 11 | 1.4427 | ||||||

| 316 N | SUS 316N | |||||||

| 316 H | X 8 CrNiMo 1712 | SUS F 316H | ||||||

| 316 H | X 8 CrNiMo 1713 | 03KH17N14M2 | ||||||

| 316 L | Z 2 CND 17-12 | X 2 CrNiMo 17 13 2 | 1.4404 | X 2 CrNiMo 1712 | SUS 316L | 316S11 | X 3 CrNiMo 17 12 2 | |

| Z 2 CND 17-12-Az | X 2 CrNiMoN 17 12 2 | 1.4406 | X 2 CrNiMoN 1712 | SUS 316LN | 03KH16N15M3 | |||

| 316 L | Z 2 CND 17-13 | X 2 CrNiMo 18 14 3 | 1.4435 | X 2 CrNiMo 1713 | 316S13 | X 3 CrNiMo 17 13 3 | ||

| Z 2 CND 17-13-Az | X 2 CrNiMoN 17 13 3 | 1.4429 | X 2 CrNiMoN 1713 | 08KH17N13M2T 10KH17N13M2T | ||||

| Z6 CNDT 17-12 | X 6 CrNiMoTi 17 12 2 | 1.4571 | X 6 CrNiMoTi 1712 | 08KH17N13M2T 10KH17N13M2T | 320S31 | X 6 CrNiMoTi 17 12 2 | ||

| X 10 CrNiMoTi 18 12 | 1.4573 | X 6 CrNiMoTi 1713 | 08KH16N13M2B | 320S33 | X 6 CrNiMoTI 17 13 3 | |||

| Z 6 CNDNb 17-12 | X 6 CrNiMoNb 17 12 2 | 1.458 | X 6 CrNiMoNb 1712 | 09KH16N15M3B | X 6 CrNiMoNb 17 12 2 | |||

| X 10 CrNiMoNb 18 12 | 1.4583 | X 6 CrNiMoNb 1713 | X 6 CrNiMoNb 17 13 3 | |||||

| 321 | Z 6 CNT 18-10 | X 6 CrNiTi 18 10 X 12 CrNiTi 18 9 | 1.4541 1.4878 | X 6 CrNiTi 1811 | SUS 321 | 12KH18N10T | 321S31 | X 6 CrNiTi 18 10 |

| 321 H | X 8 CrNiTi 1811 | SUS 321H | 321S20 | |||||

| 329 | X 8 CrNiMo 27 5 | 1.446 | SUS 329J1 | 08KH18N12B | ||||

| 347 | Z 6 CNNb 18-10 | X 6 CrNiNb 18 10 | 1.455 | X 6 CrNiNb 1811 | SUS 347 | 347S31 | X 6 CrNiNb 18 10 | |

| 347 H | X 8 CrNiNb 1811 | SUS F 347H | ||||||

| 904L | Z 12 CNDV 12-02 | 1.4939 | ||||||

| X 20 CrNiSi 25 4 | 1.4821 | |||||||

| UNS 31803 | X 2 CrNiMoN 22 5 | 1.4462 | ||||||

| UNS 32760 | Z 3 CND 25-06Az | X 3 CrNiMoN 25 7 | 1.4501 | 12Kh13 |