Hole Pattern

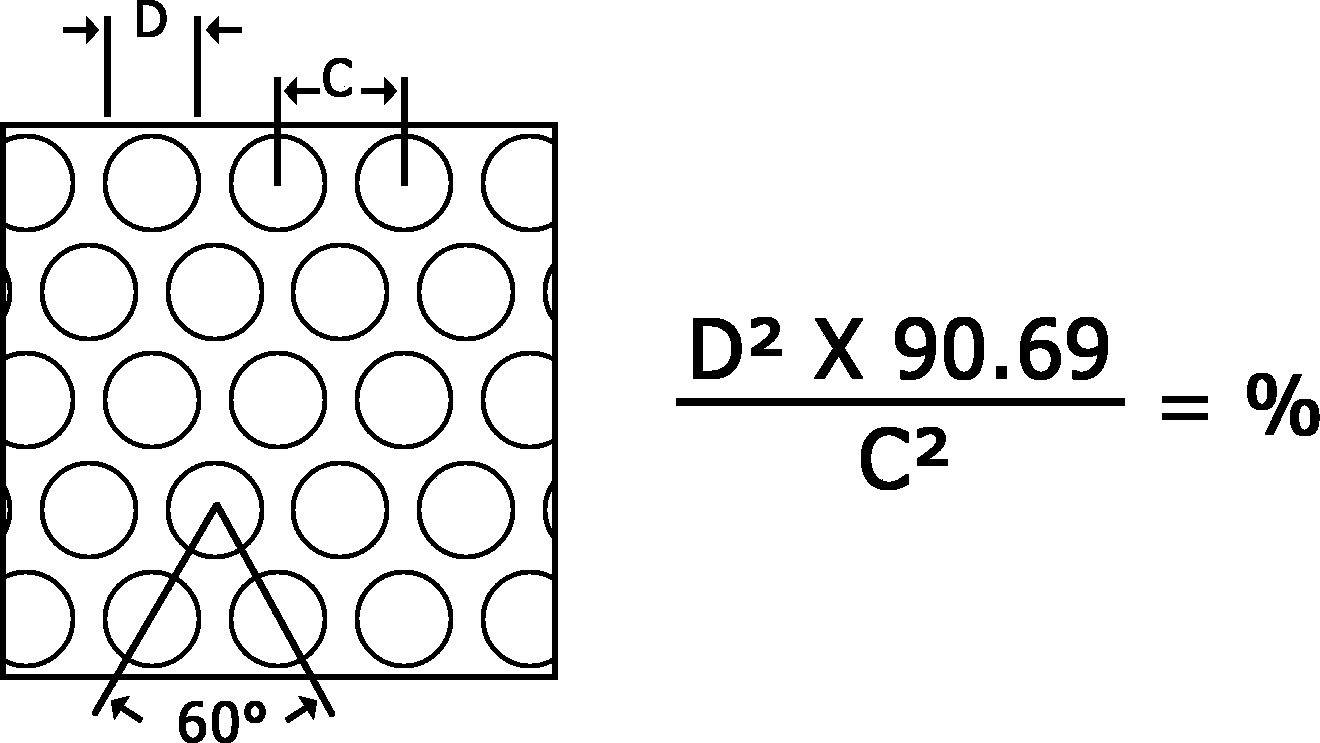

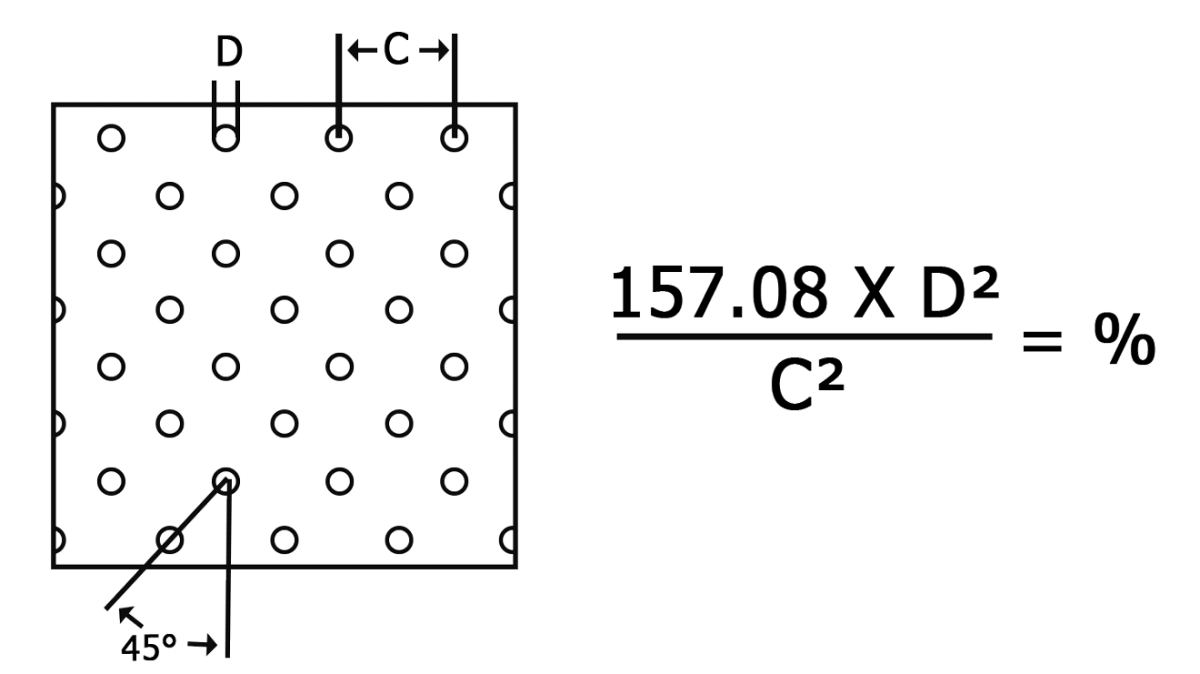

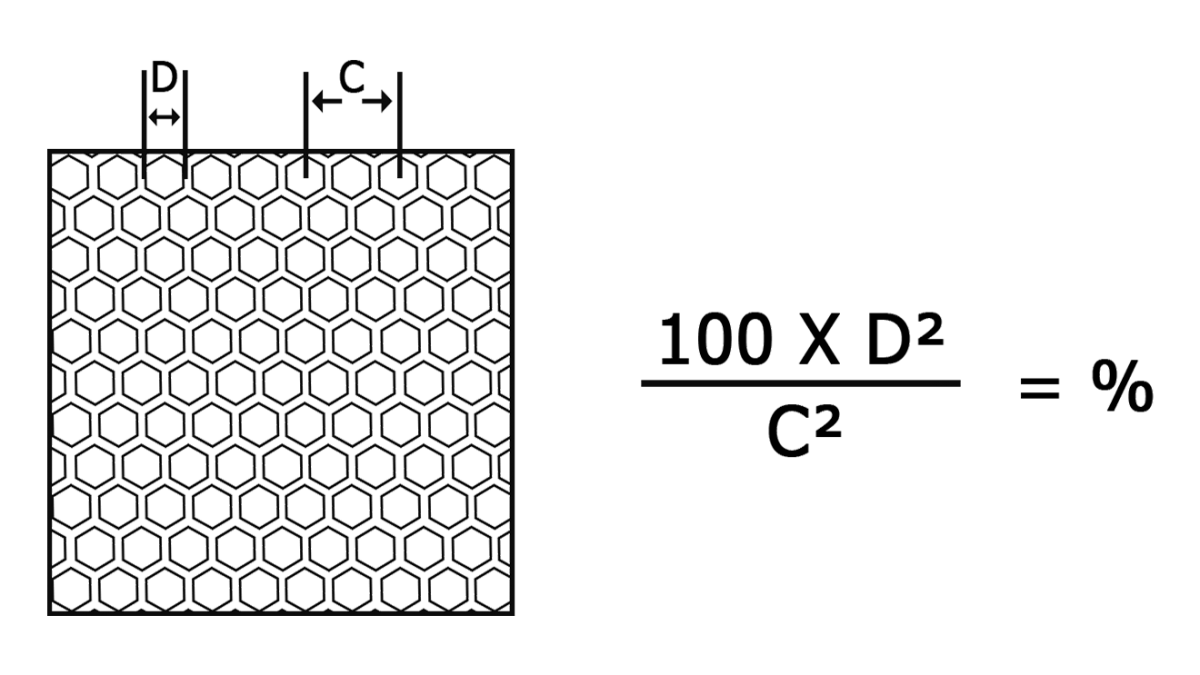

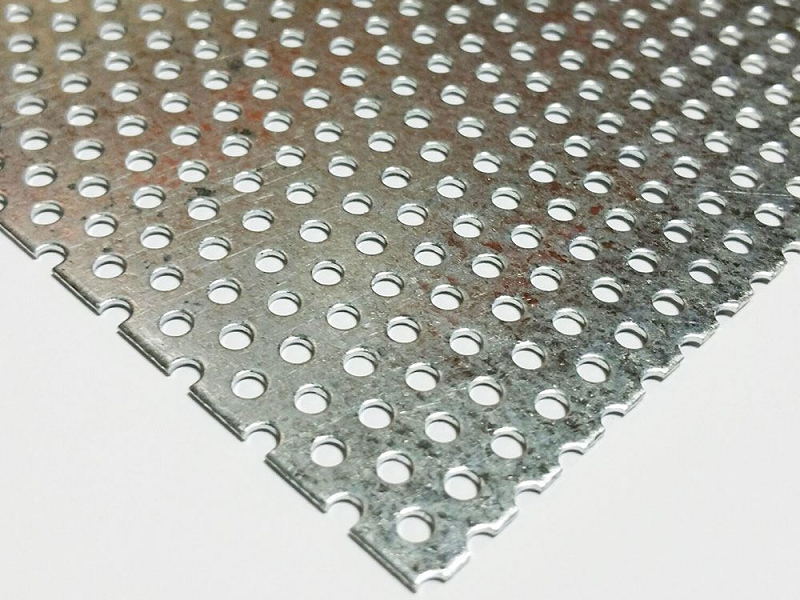

- Round Hole Perforated Metal

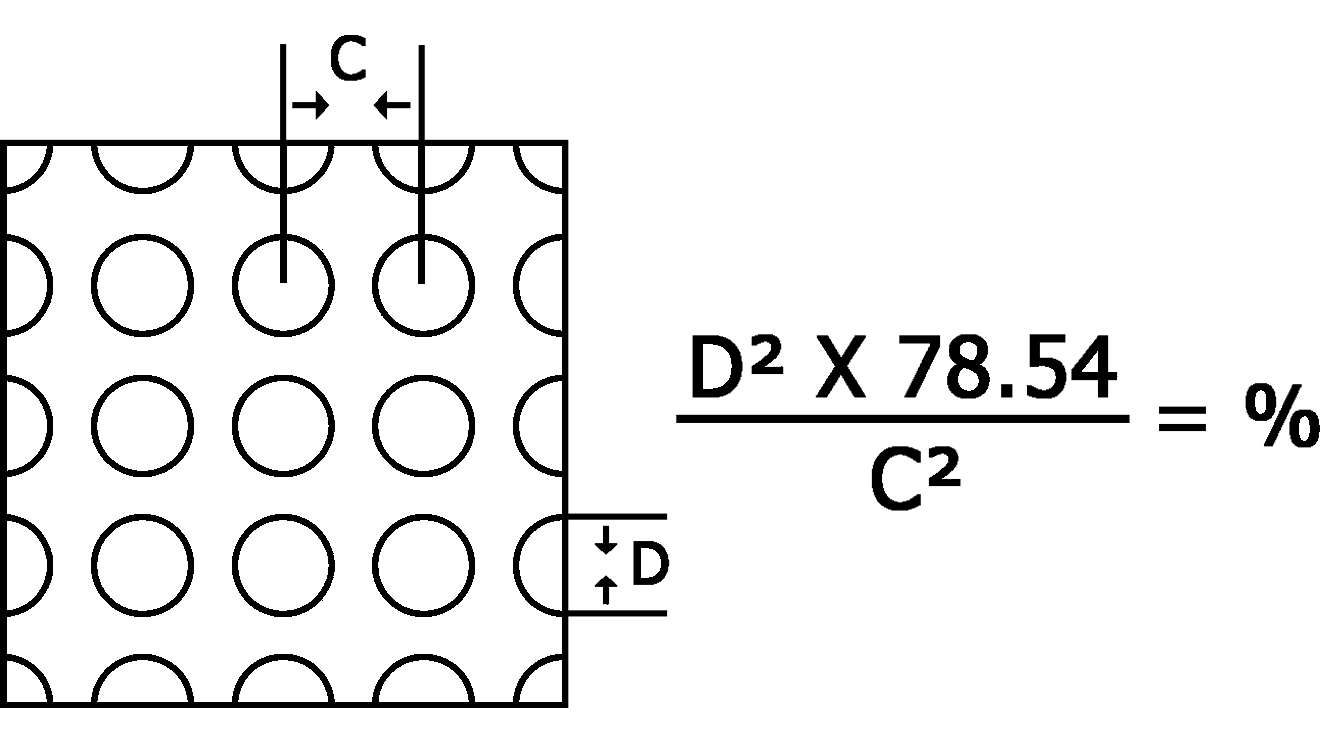

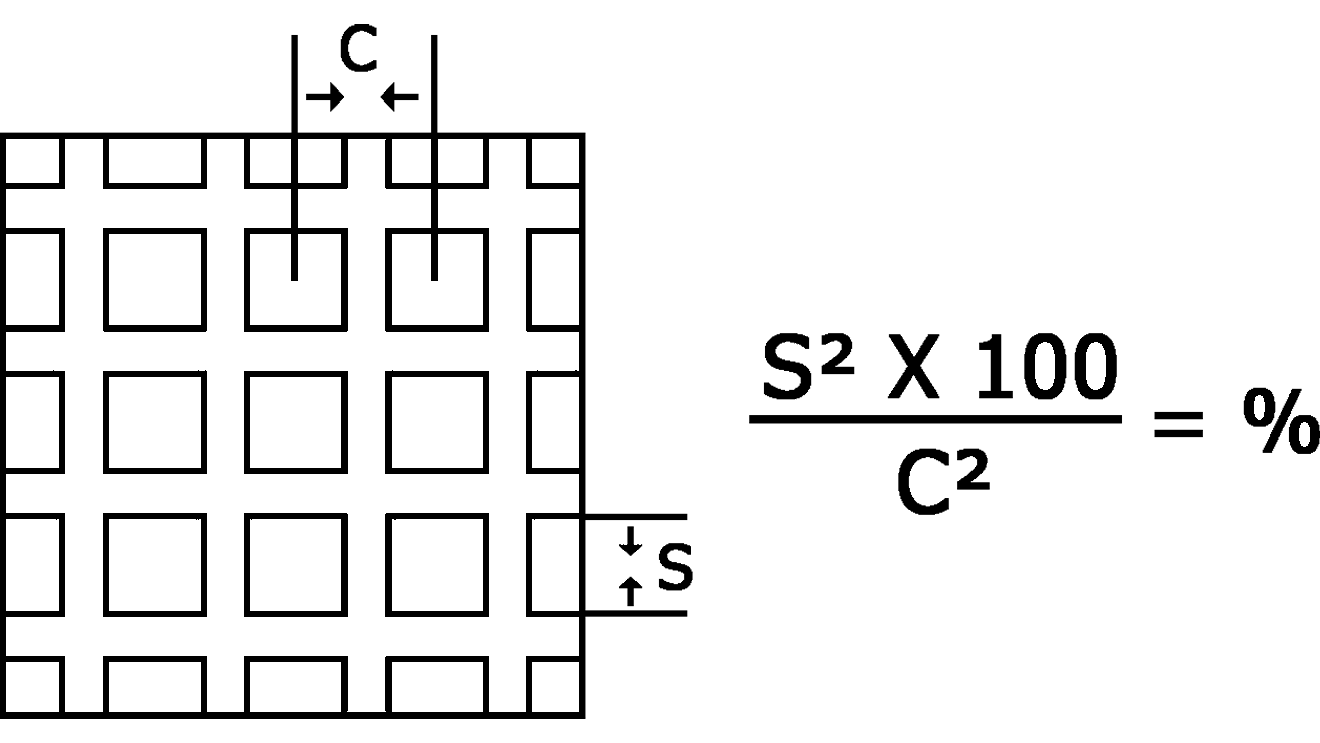

- Square Hole Perforated Metal

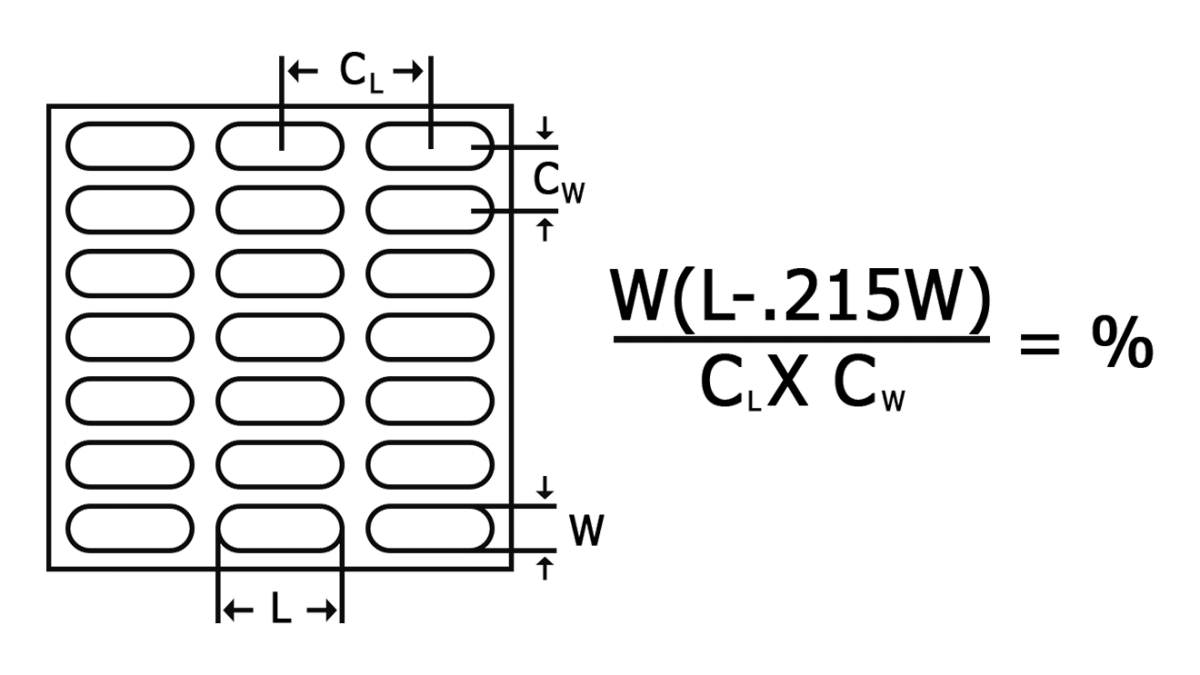

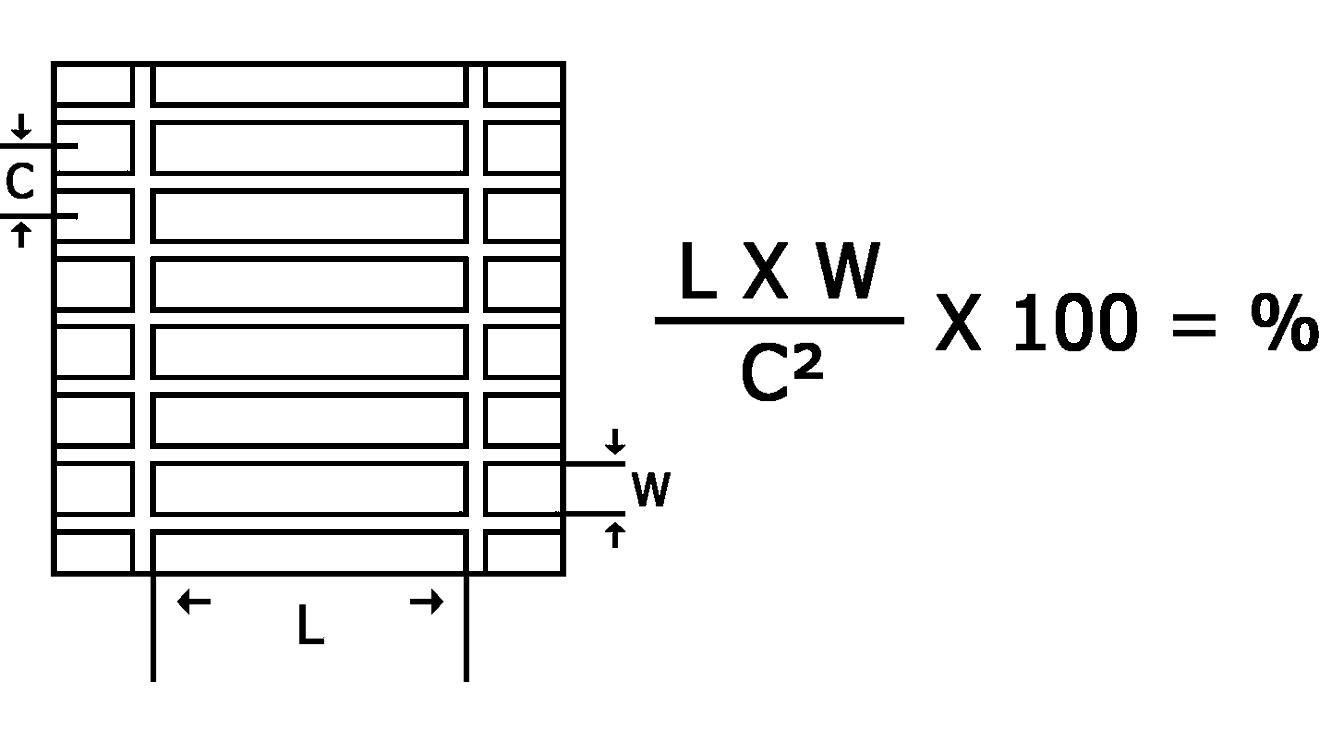

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Open Percent Formulas

Perforation Material

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Steel Perforated Metal

- Galvanized Steel Perforated Metal

- Brass Perforated Metal

Perforated Metal Applications

- Filters

- Perforated Screen Plates

- Aluminum Exterior Building Facades

- Protective Cover For Rquipment

- Perforated Metal Ceilings

- Perforated Metal Infill Panels

- Anti-Skid Perforated Sheet

- Perforated Metal Noise Barrier

430 Stainless Steel Wire Cloth & Grating

Perforated & Expanded 430 SS

Marco offers 430 stainless steel wire cloth and grating, as well as perforated and expanded 430 SS. Stainless steel 430 has lower alloy content than stainless steel 304 and is used for highly polished trim applications in mild atmospheres. 430 SS has good formability, ductility, low work hardening, corrosion resistance, oxidation resistance, good thermal conductivity, attractive finish, and is excellent for drawing. Stainless steel 430 is used in nitric acid and food processing. Other common uses include heat exchangers, vaults, tubing, builder’s hardware, kitchen trims and appliance trims.

Principal Design Features: A basic ferritic non-heat treatable stainless steel. Its strengths are in ductility, formability, good corrosion and oxidation resistance, thermal conductivity and finish quality.

Applications: Appliance, automotive and architectural trim, vaults, heat exchangers, scientific apparatus and vending machine components.

Machinability: Rated at 60% of B1112. Relatively easily machined in all common procedures.

Forming: Has similar forming characteristics to 304 stainless steel without the same degree of ductility. But, it does not work harden greatly.

Welding: All common welding methods used for stainless will be successful with 430. Filler metal should be AWS E/ER308 or 312.

430 Chemistry

| Carbon | 0.12 max |

| Chromium | 16 – 18 |

| Iron | Balance |

| Manganese | 1 max |

| Phosphorus | 0.04 max |

| Silicon | 1 max |

| Sulphur | 0.03 max |

430 Physical Data

| Density (lb / cu. in.) | 0.276 |

| Specific Gravity | 7.75 |

| Specific Heat (Btu/lb/Deg F – [32-212 Deg F]) | 0.11 |

| Electrical Resistivity (microhm-cm (at 68 Deg F)) | 360 |

| Melting Point (Deg F) | 2750 |

| Modulus of Elasticity Tension | 29 |