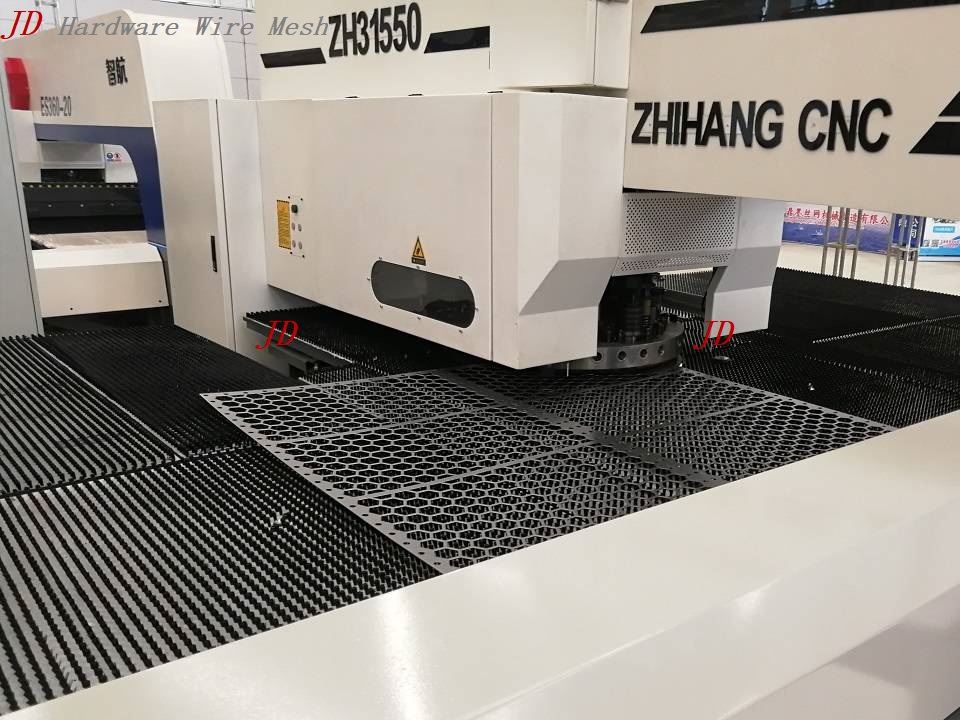

CNC Bending

Utilizes CNC equipment and quality tooling to assure accurate dimensions and quality on our finished bent plates. we are able to supply our customers with time savings, manufacturing efficiencies, lower costs, and high-quality products — providing the best value for our clients and keeping us competitive in the global marketplace.

Advantages of CNC Bending:

CNC programming with precision and consistency.

It adopts an all-steel welded structure with sufficient strength and rigidity.

Cost reduction, automation technology requires fewer workers, which not only reduces labor costs but also reduces the cost of workpiece loss.

Saving time and improving efficiency, CNC manufacturing accelerates the speed of human labor in the production process.

4 Axis Folding

Our equipment has precision forming capabilities by using 4 axis press brakes, which allows the forming of simple parts all the way to intricately bent precision components.

Metal sheets out of stainless steel, mild steel and aluminium can be bent.

Our equipment has the ability to bent the metal sheet without leaving any marks.

In-process measurement

The bending process can take place in mass scale production because of the machine's ability to control the bending angle with the Automatically Controlled Bending system.

During the bending process, two integrated sensor plates measure the actual angle and the resilience of the metal sheet and control the pressure bar at the desired angle.

Intelligent Programming

Programs can be created graphically in 3D on the machine control or off line. This enables collision examination and control prior to the forming operation taking place. A substantial selection of tooling as available enabling us to produce complex bend sequences without delay.