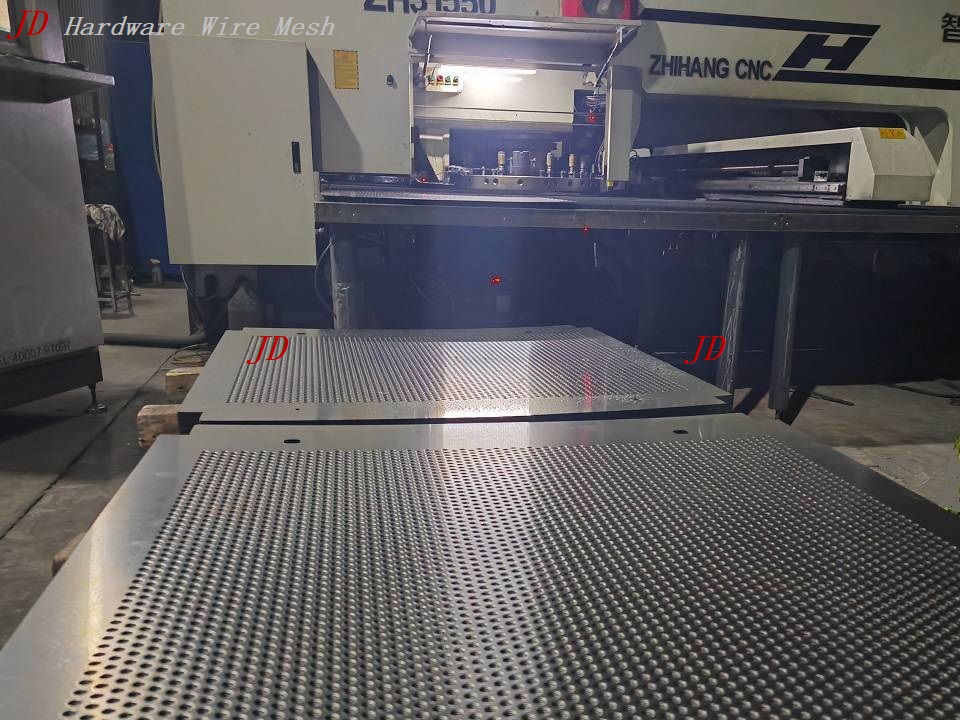

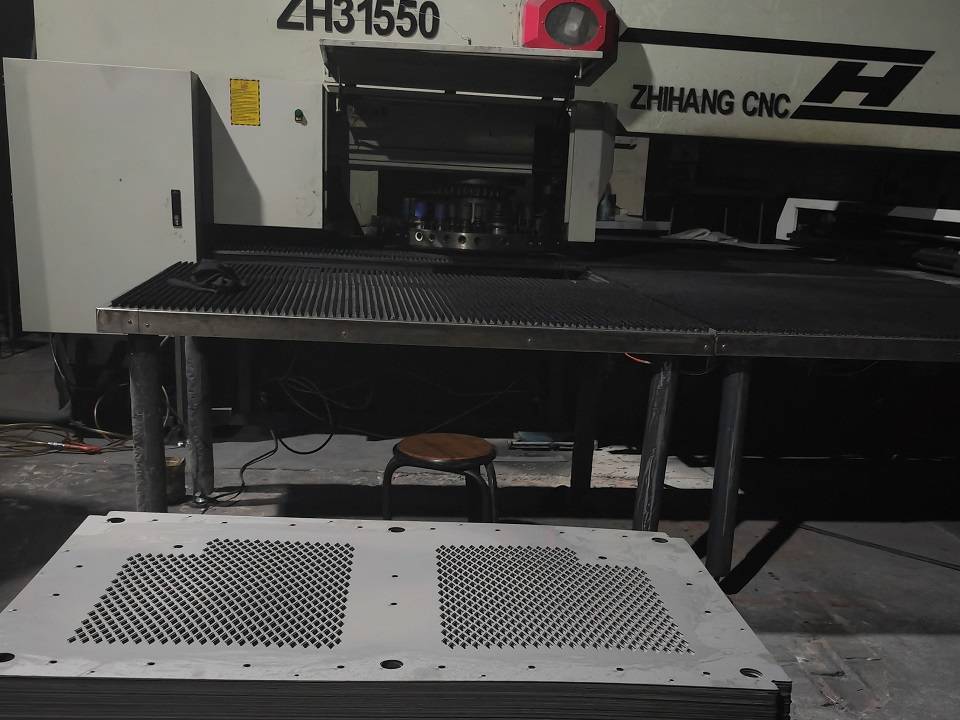

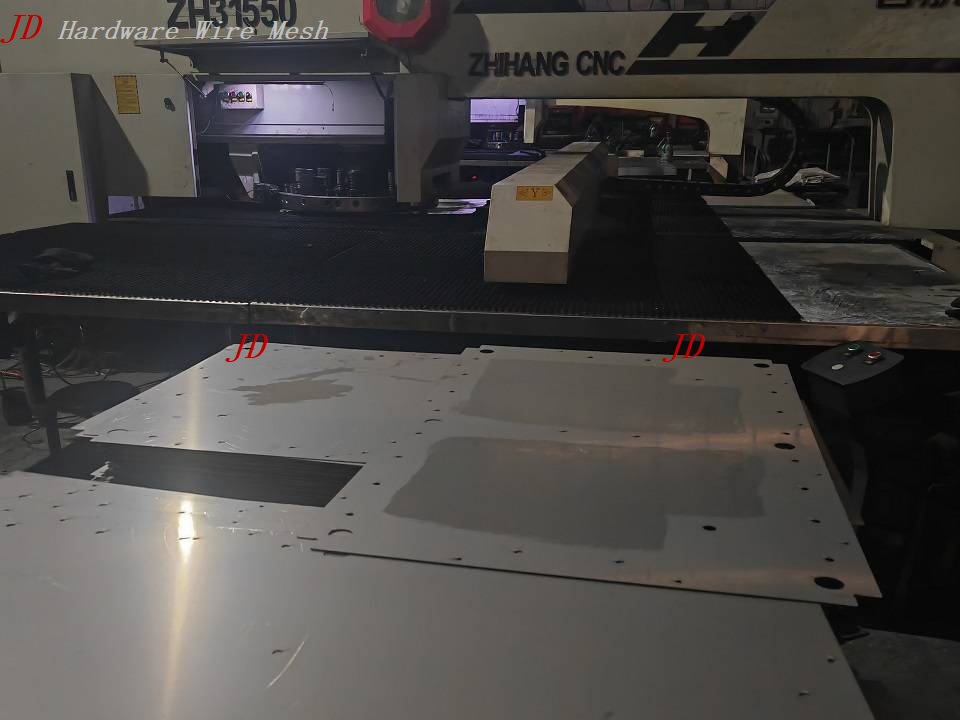

CNC Turret Punch Machine(NCT)

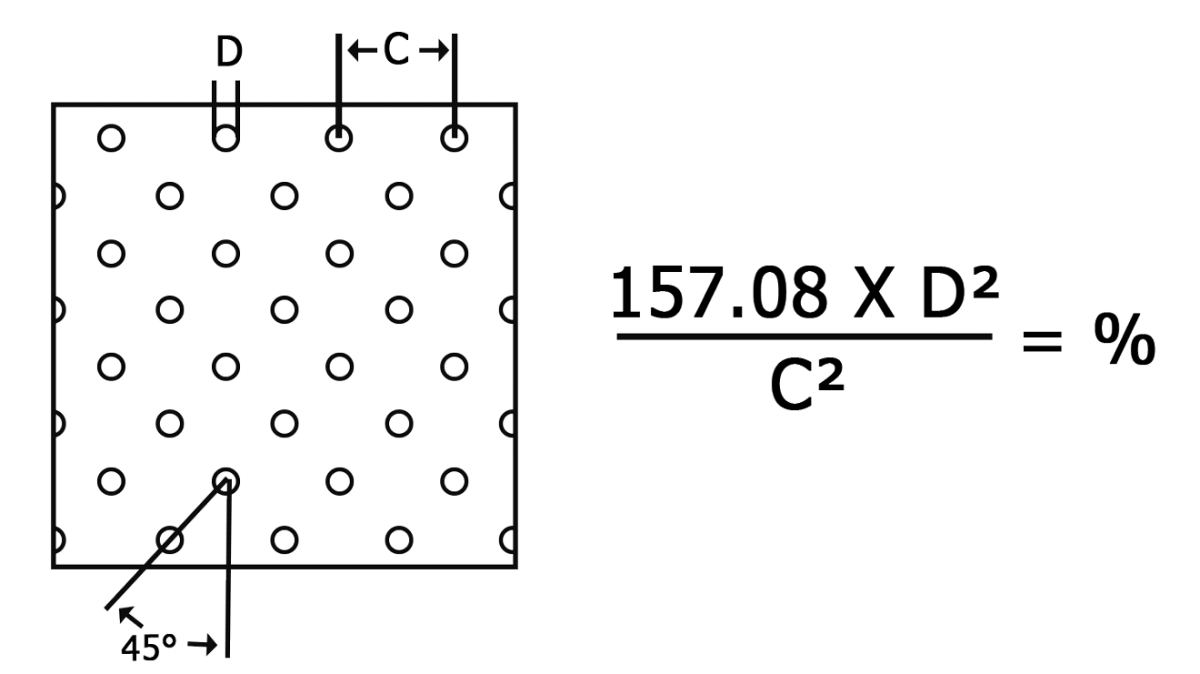

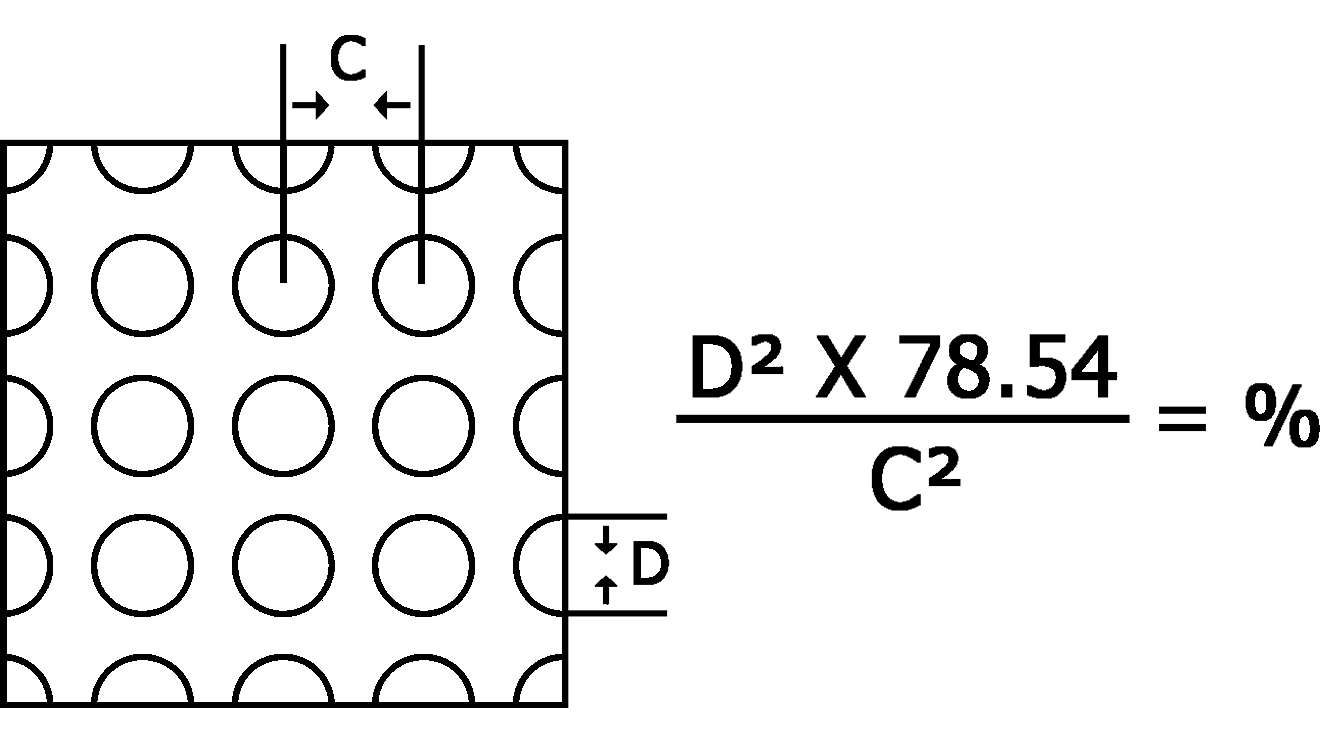

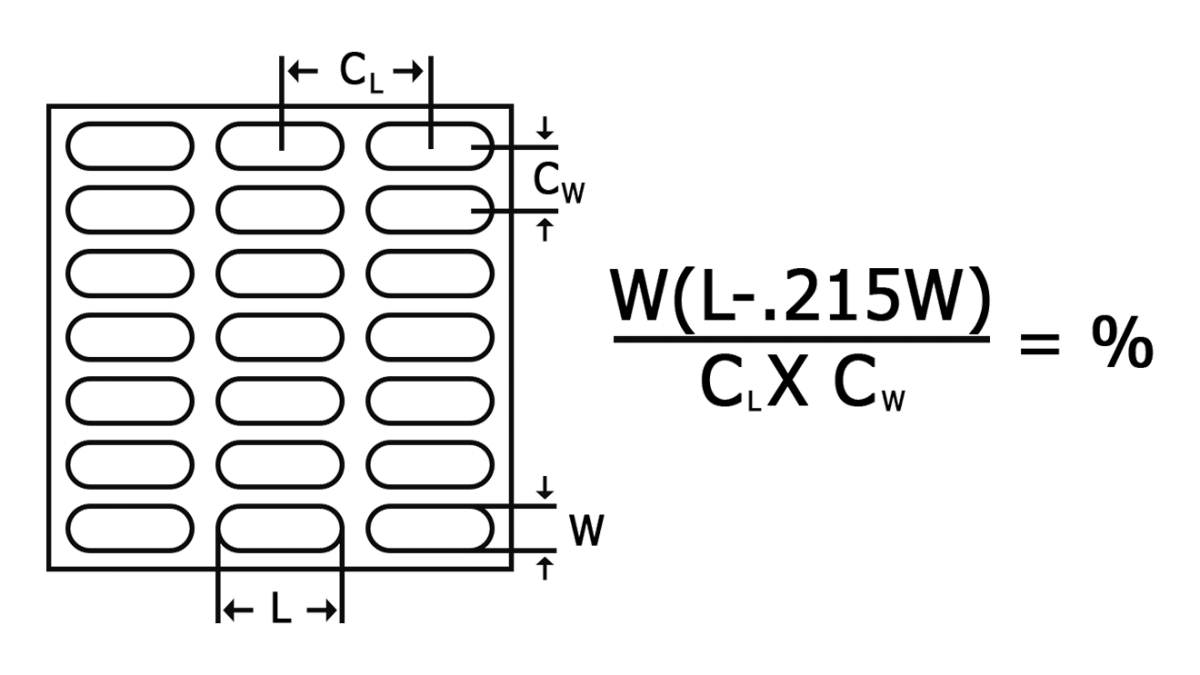

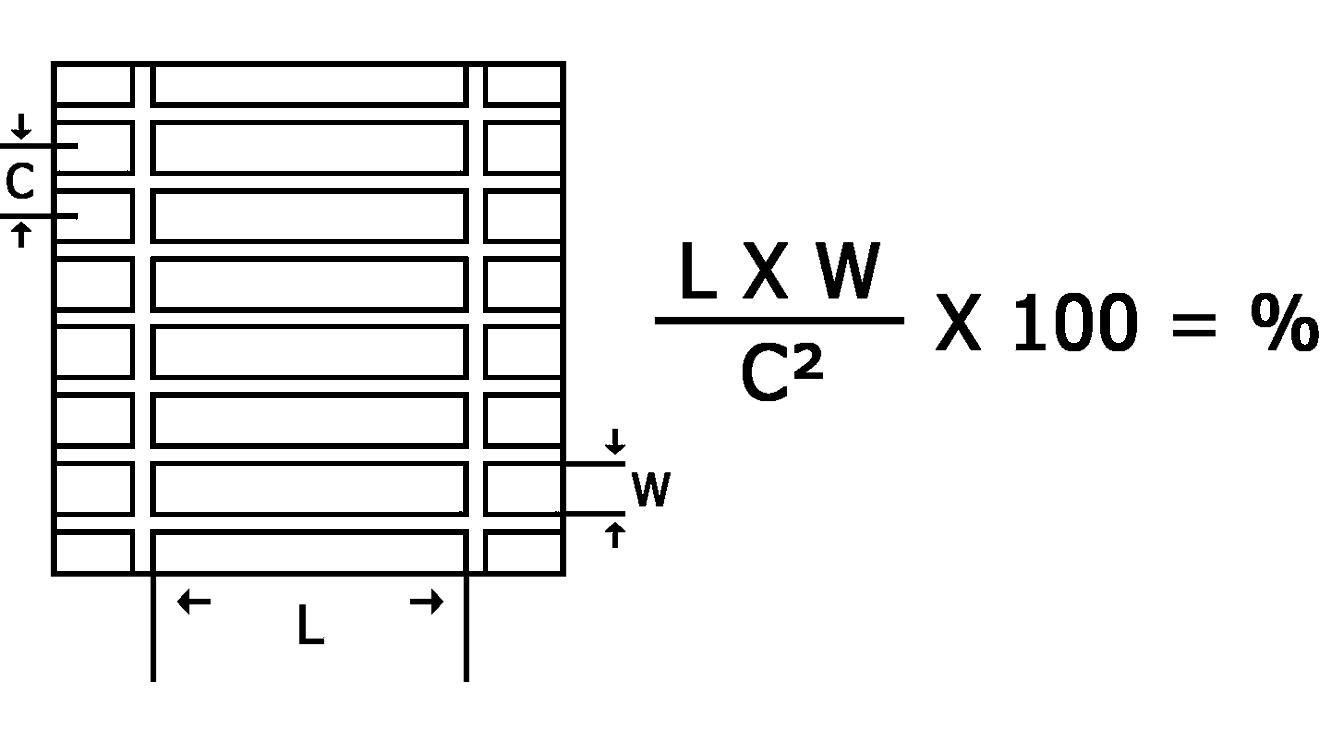

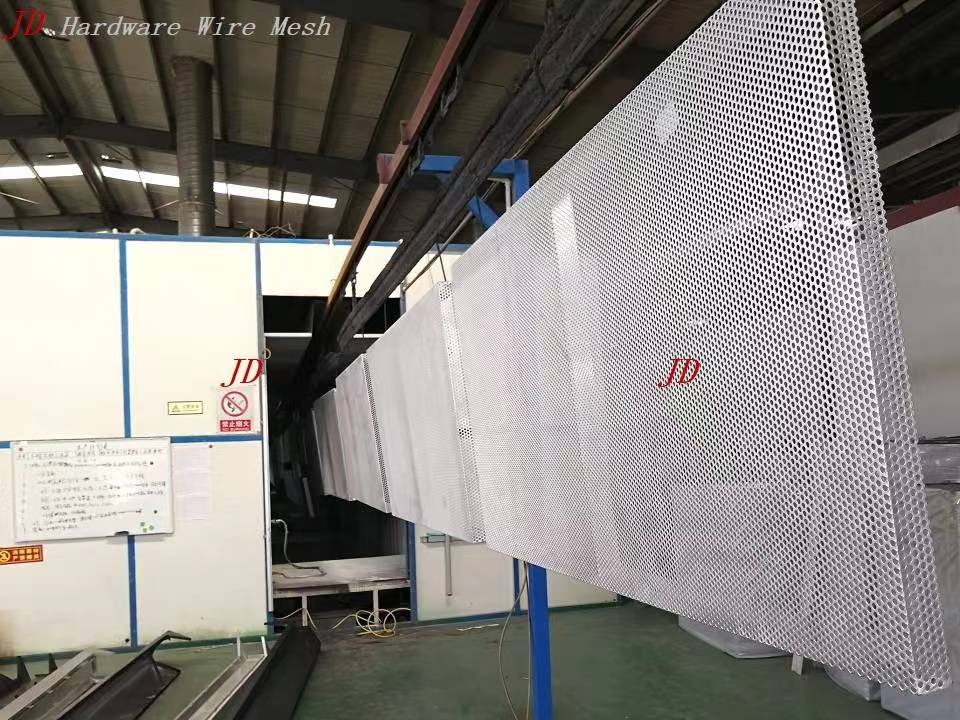

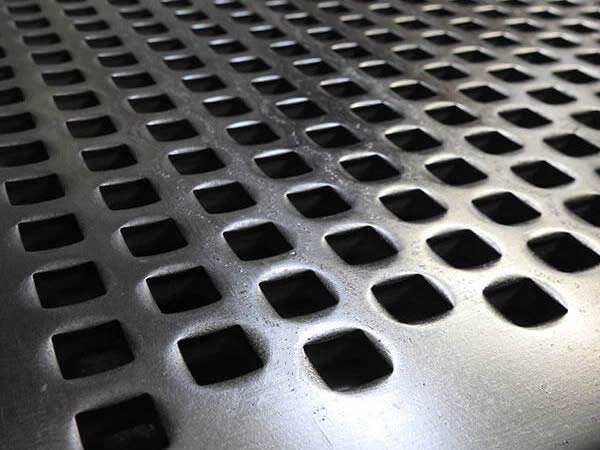

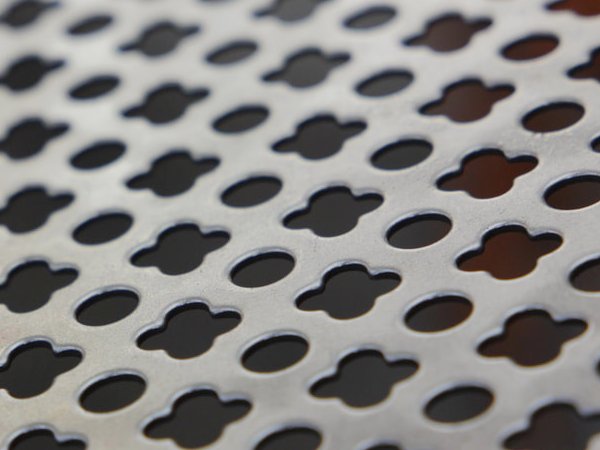

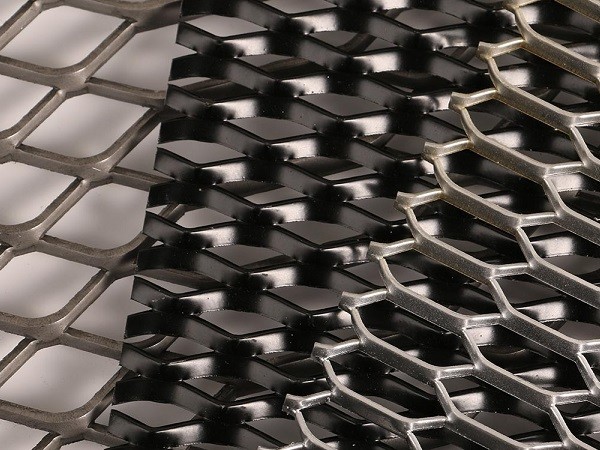

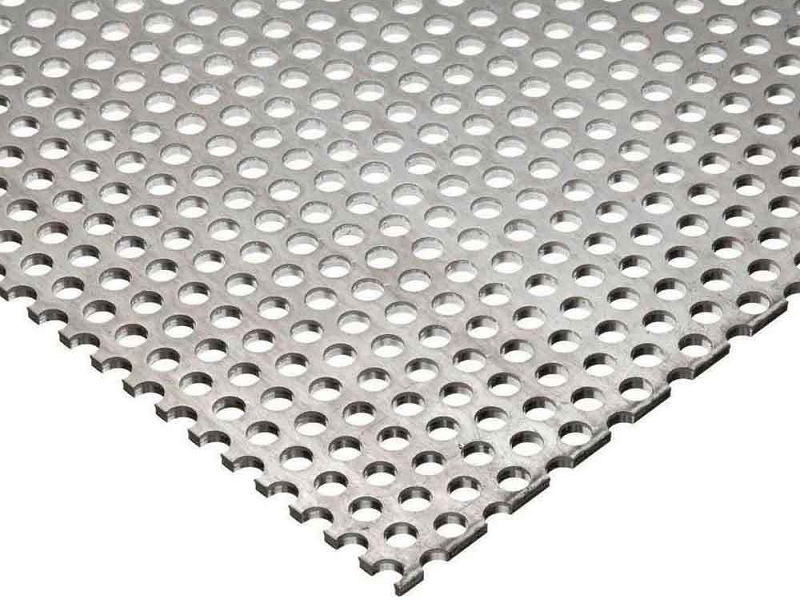

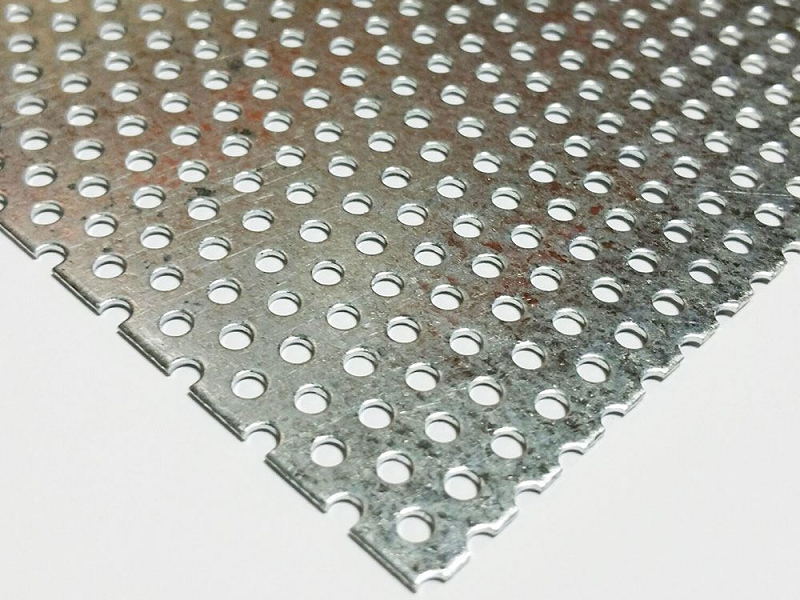

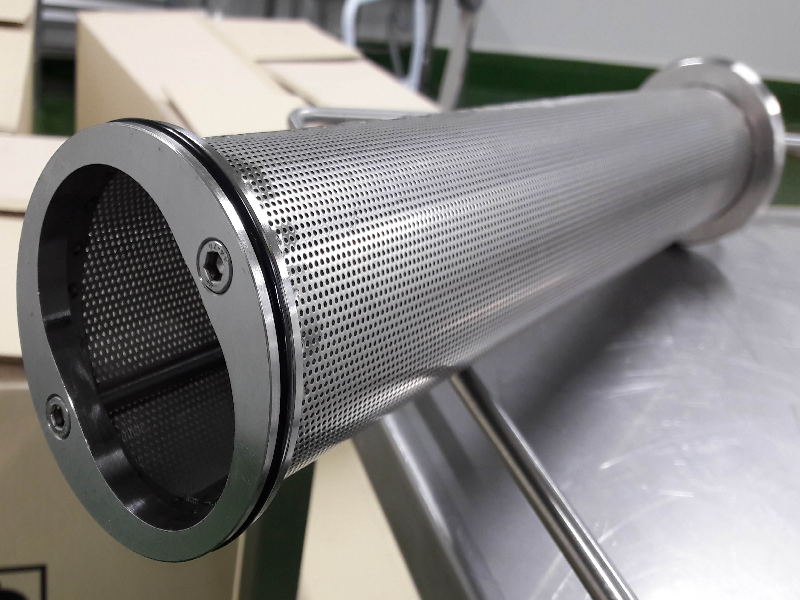

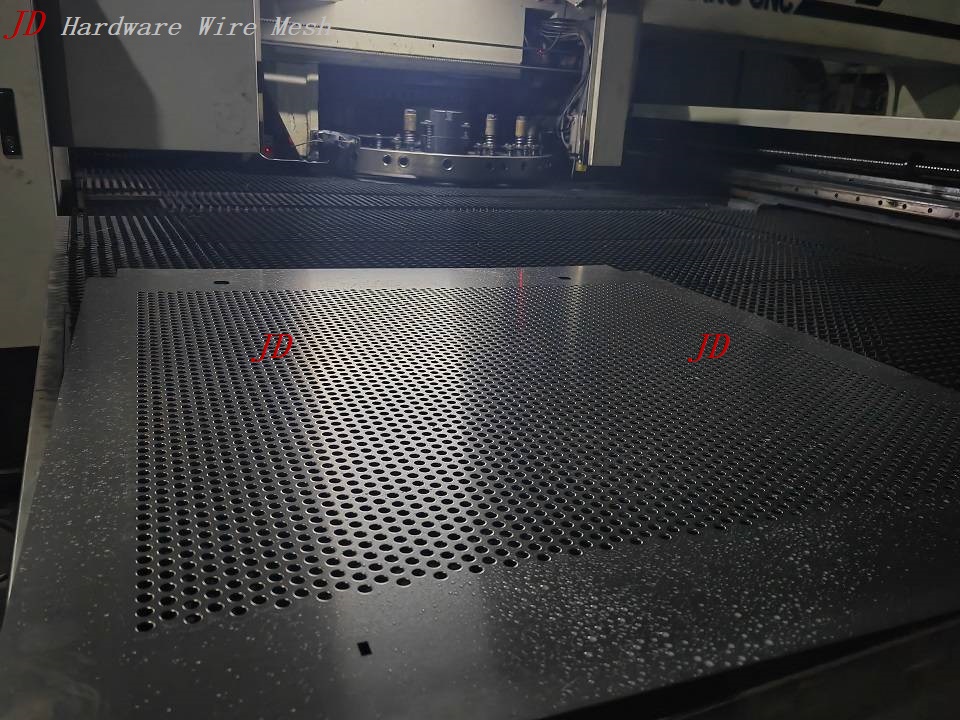

CNC turret punch machine is one of the main categories of CNC punch machines, integrating machine, electricity, fluid and gas. It is a pressure processing equipment for punching and shallow drawing and deep forming on the plate through the turret punch die. Decorative perforated plates and safety grating commonly use this process.

Advantages:

Strong adaptability to parts, can process complex shapes of parts surface.

High machining precision, stable machining quality.

Shorten production preparation time and promote modern management.

High productivity, compared with ordinary machine tools, CNC turret punch can improve production efficiency 3–5 times.

One machine multi-purpose, reduce labor intensity, save plant area.

Disadvantages:

The equipment is expensive and the initial investment of the equipment is high.

The integration of mechanical, electrical, hydraulic and computer technologies has high technical requirements for users and maintenance personnel.

Manual programming is a heavy workload when machining complex shape parts.

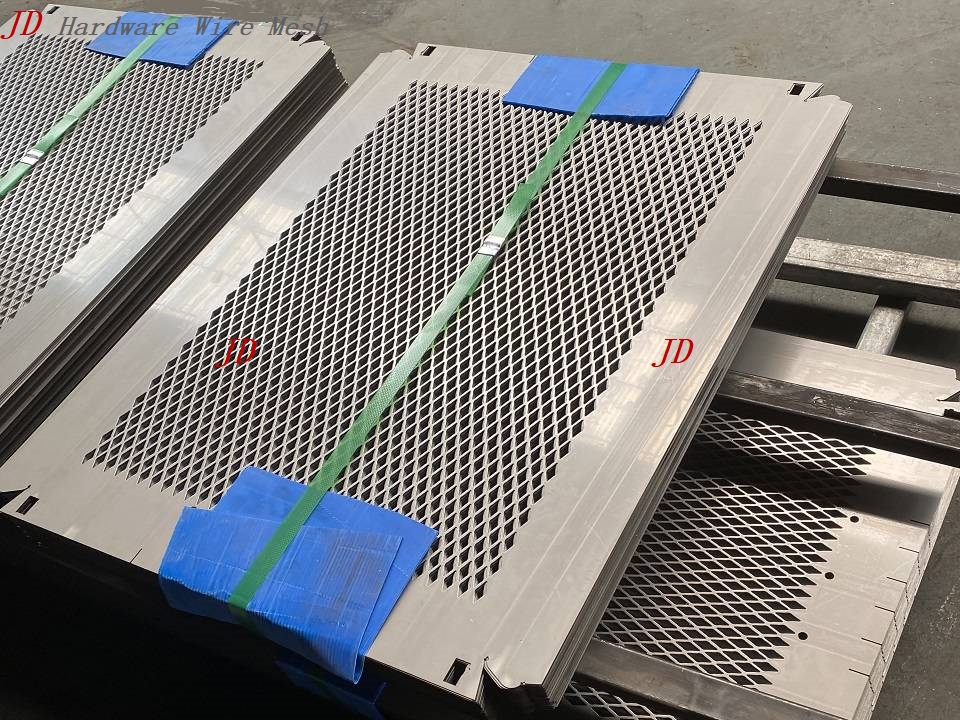

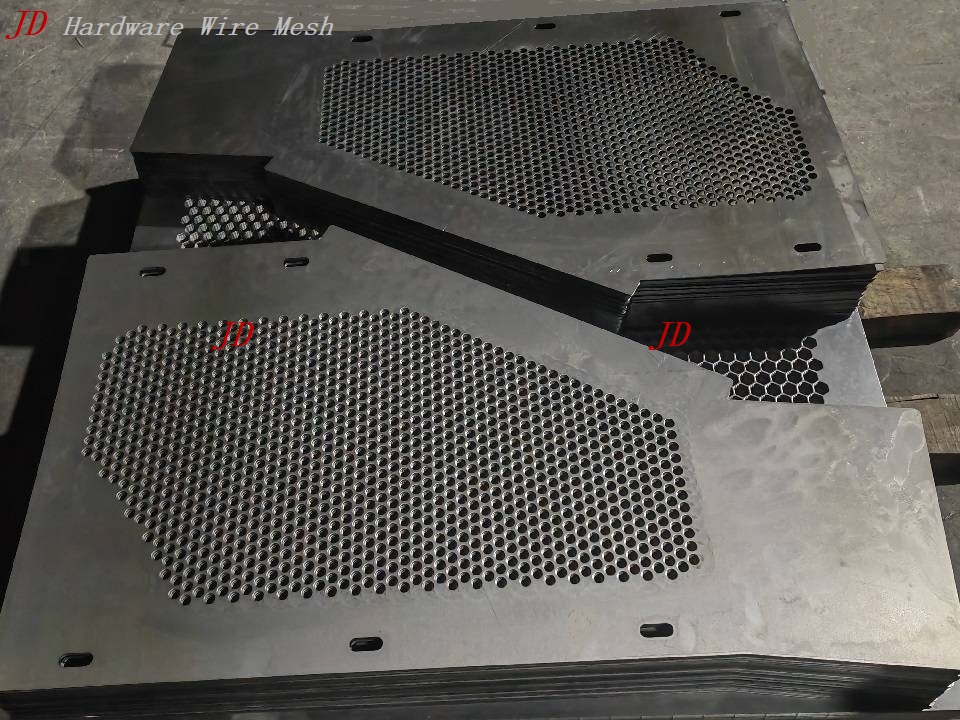

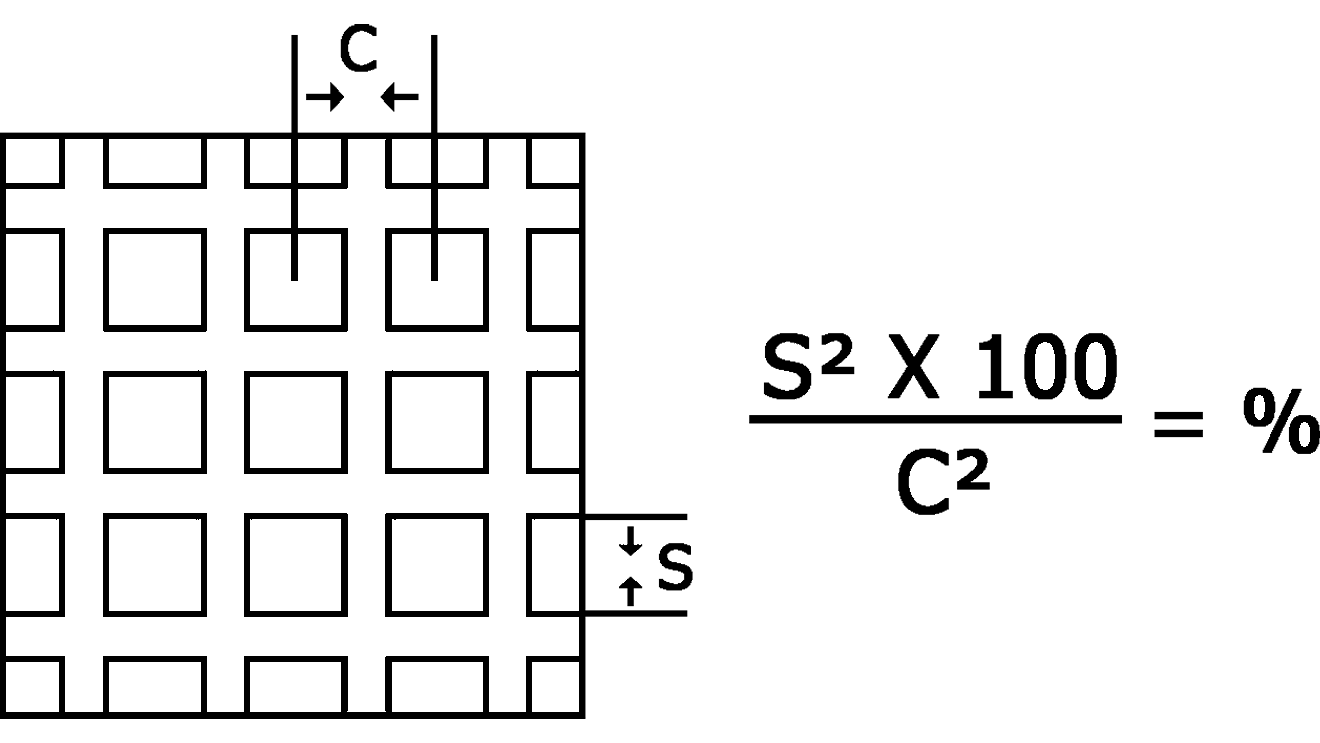

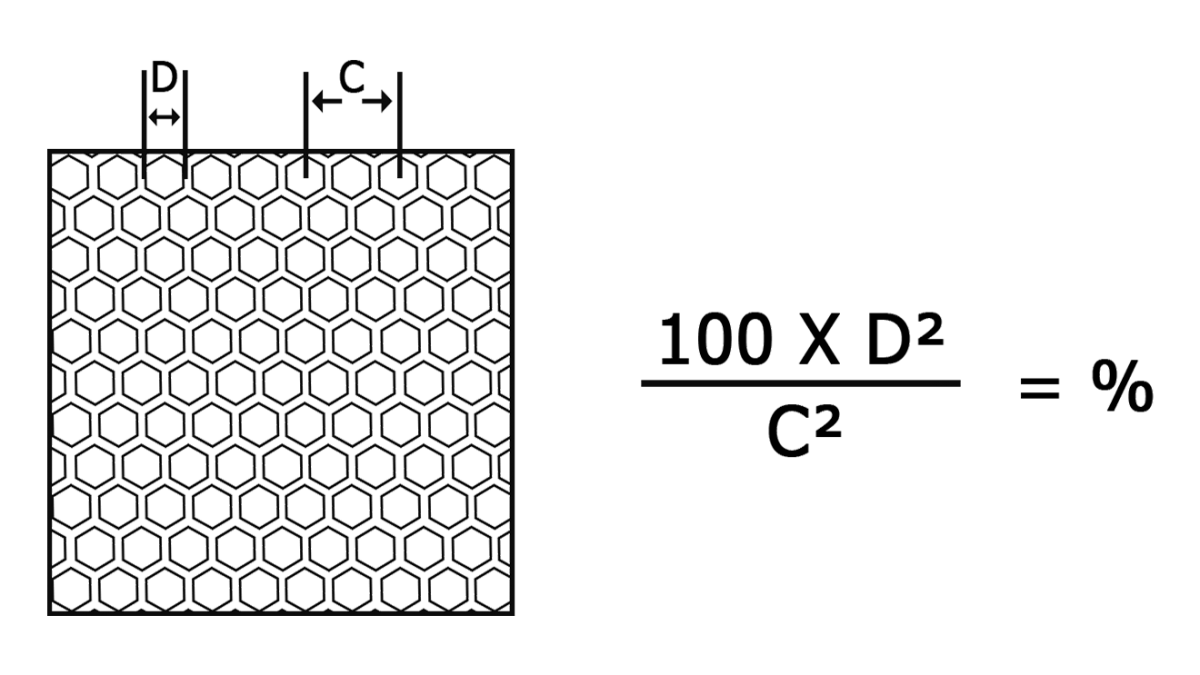

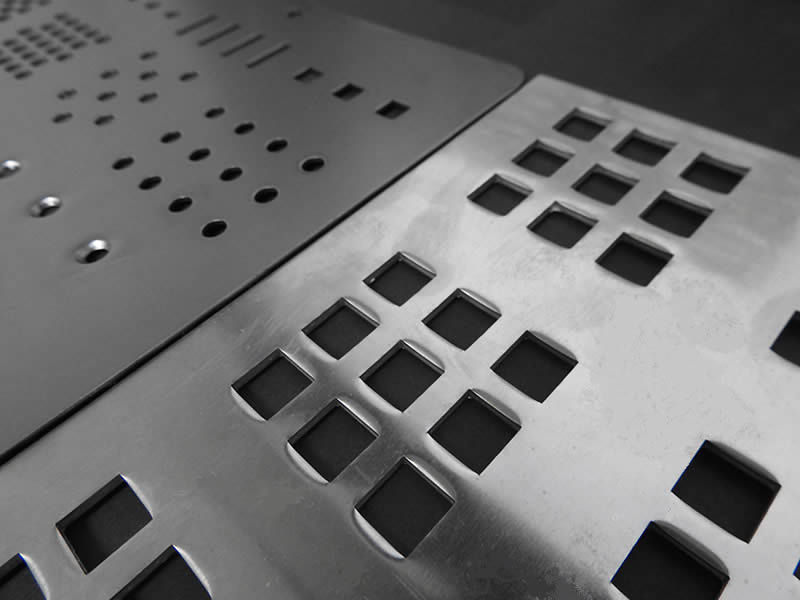

Perforated Metal Plate Specification:

Material: stainless steel, aluminum, aluminum alloy, galvanized steel, copper or brass.

Thickness: 0.5mm –3mm. Alu. up to 4 mm

Width: 1.5m.

Length: 5m.

providing the optimal punching solution for variable-mixed and variable-lot production.

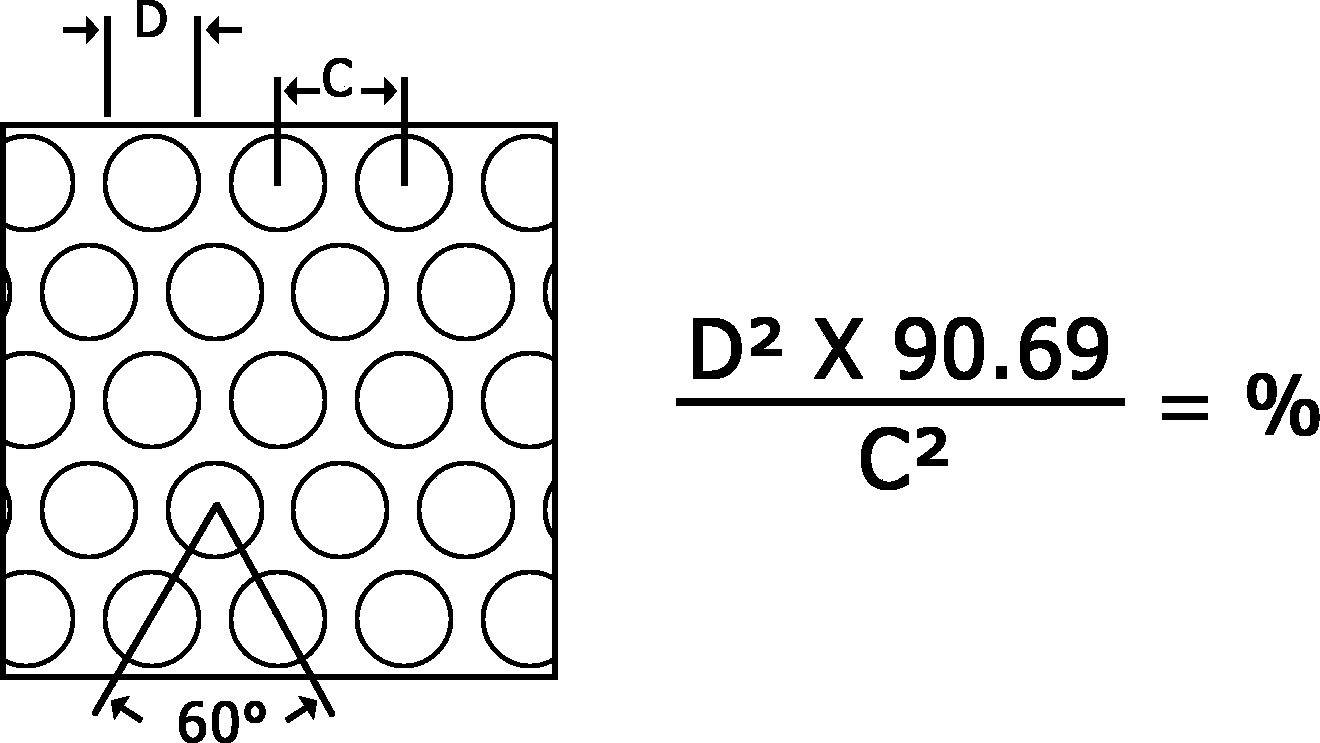

Mesh opening area: 5% – 67%.

Pattern design: available.