Hole Pattern

- Round Hole Perforated Metal

- Square Hole Perforated Metal

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Expanded Metal Mesh

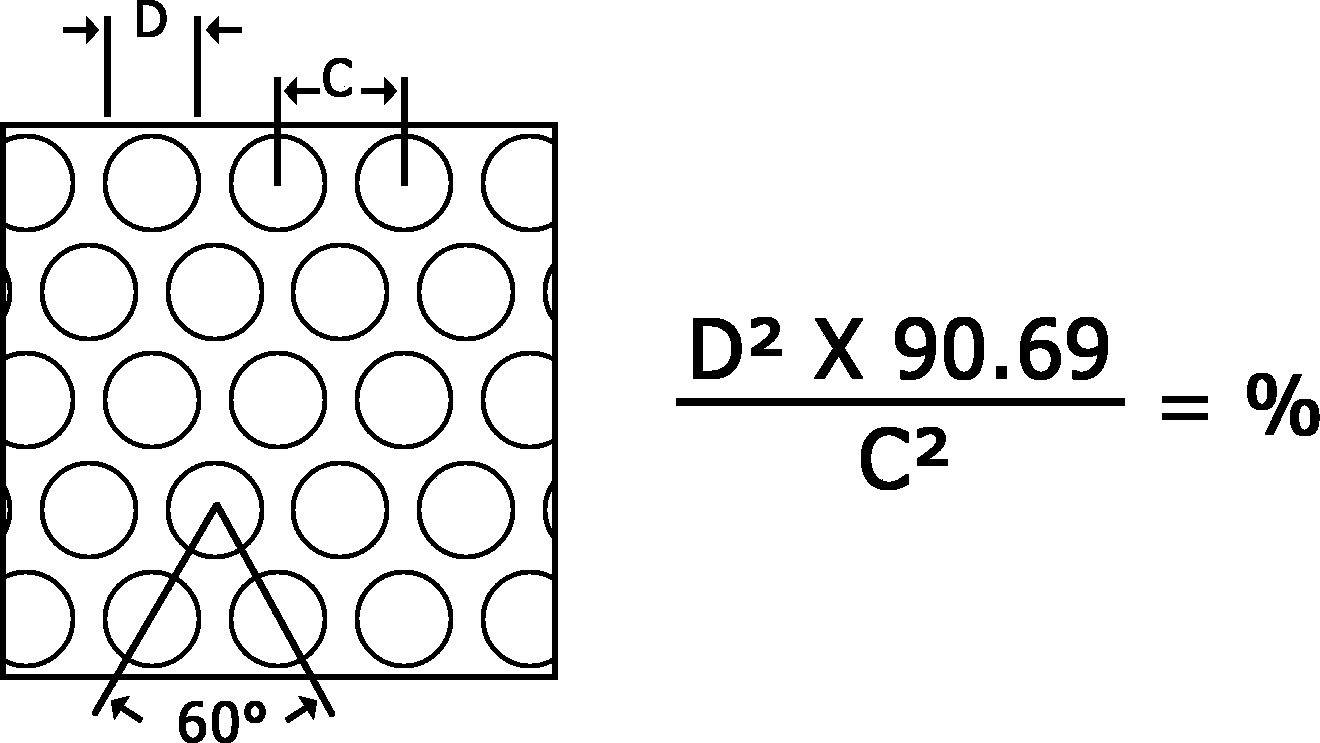

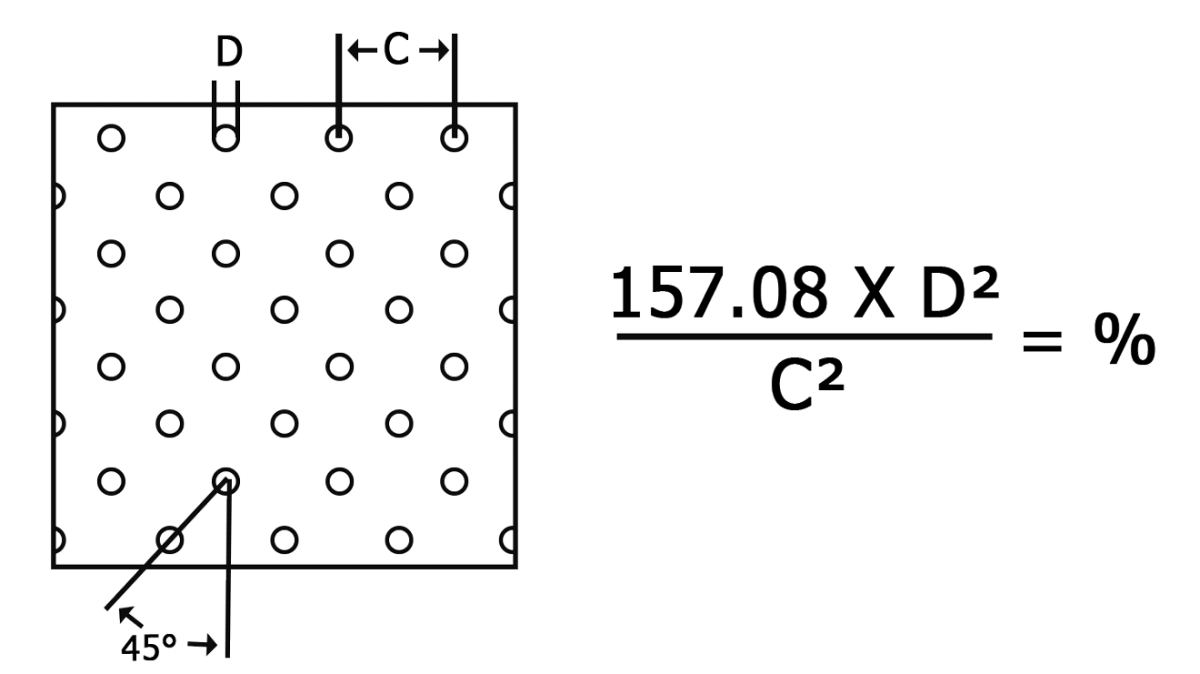

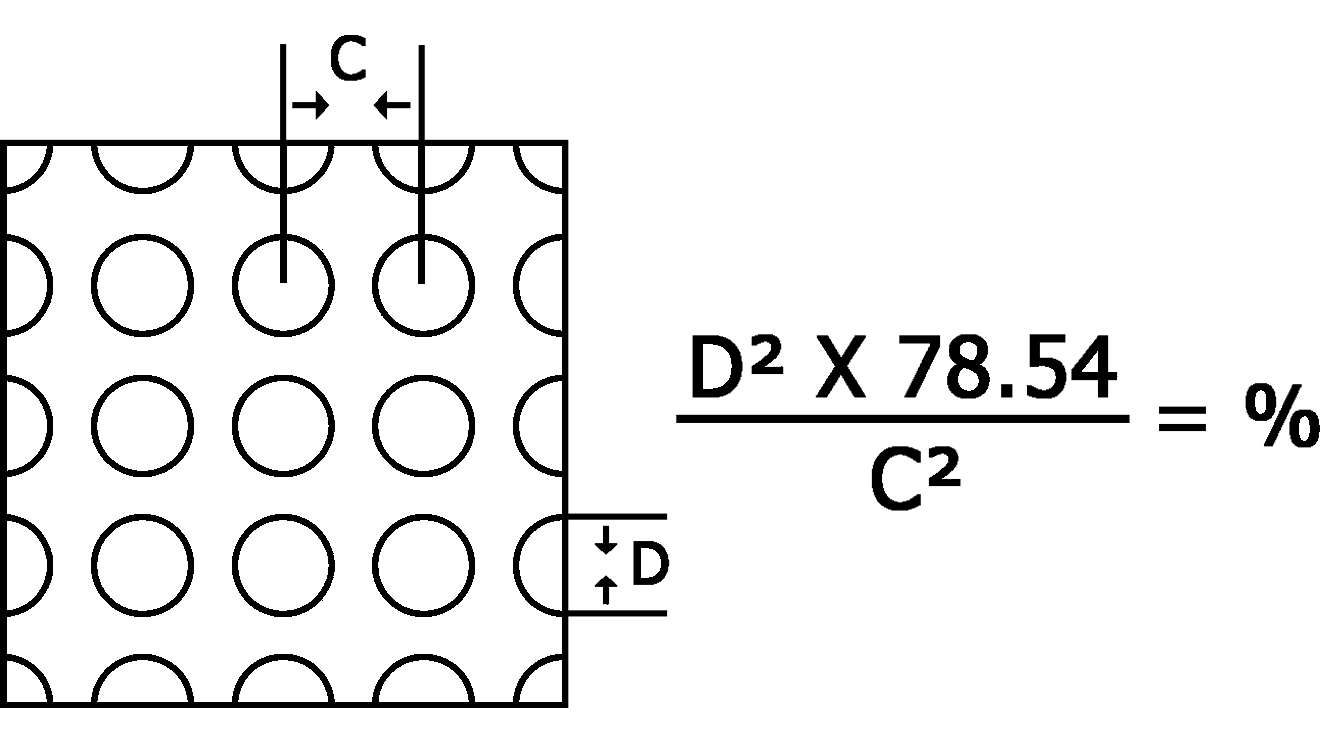

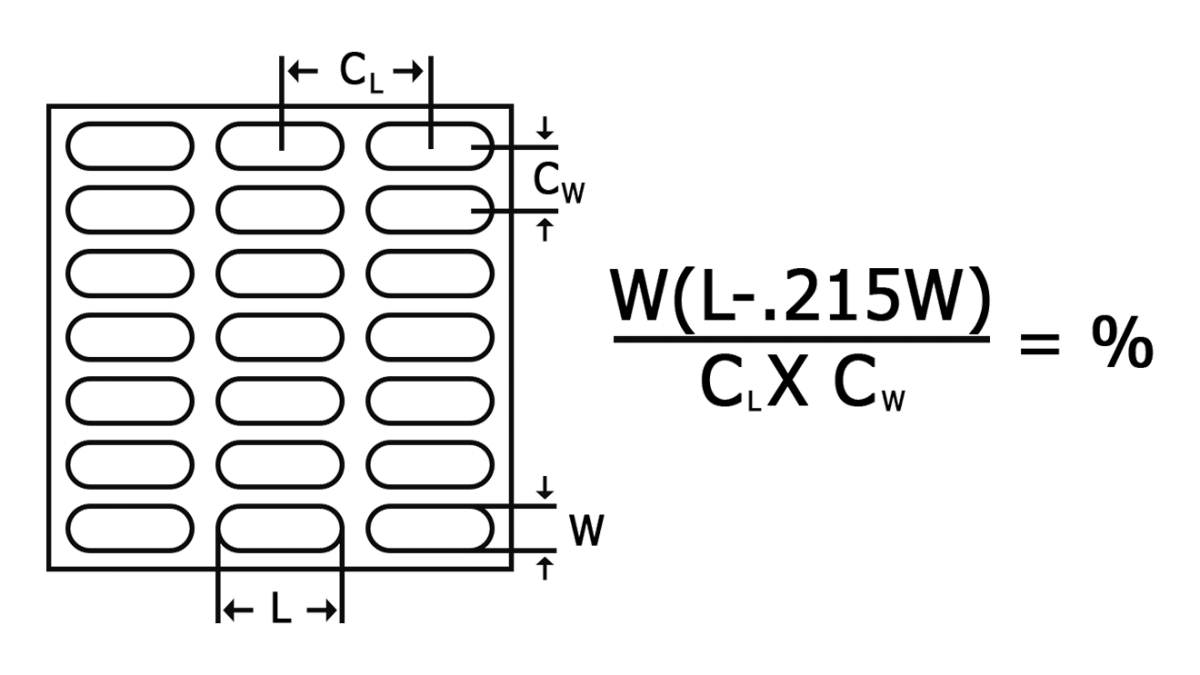

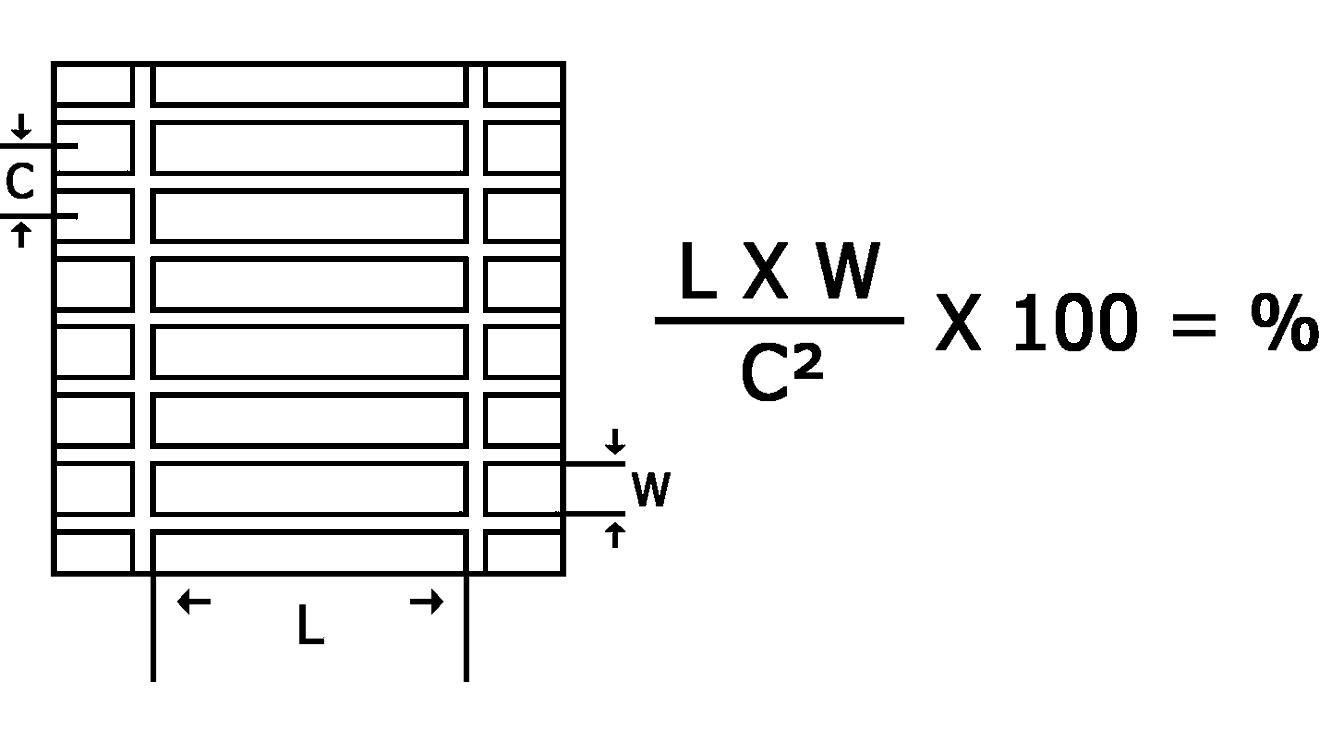

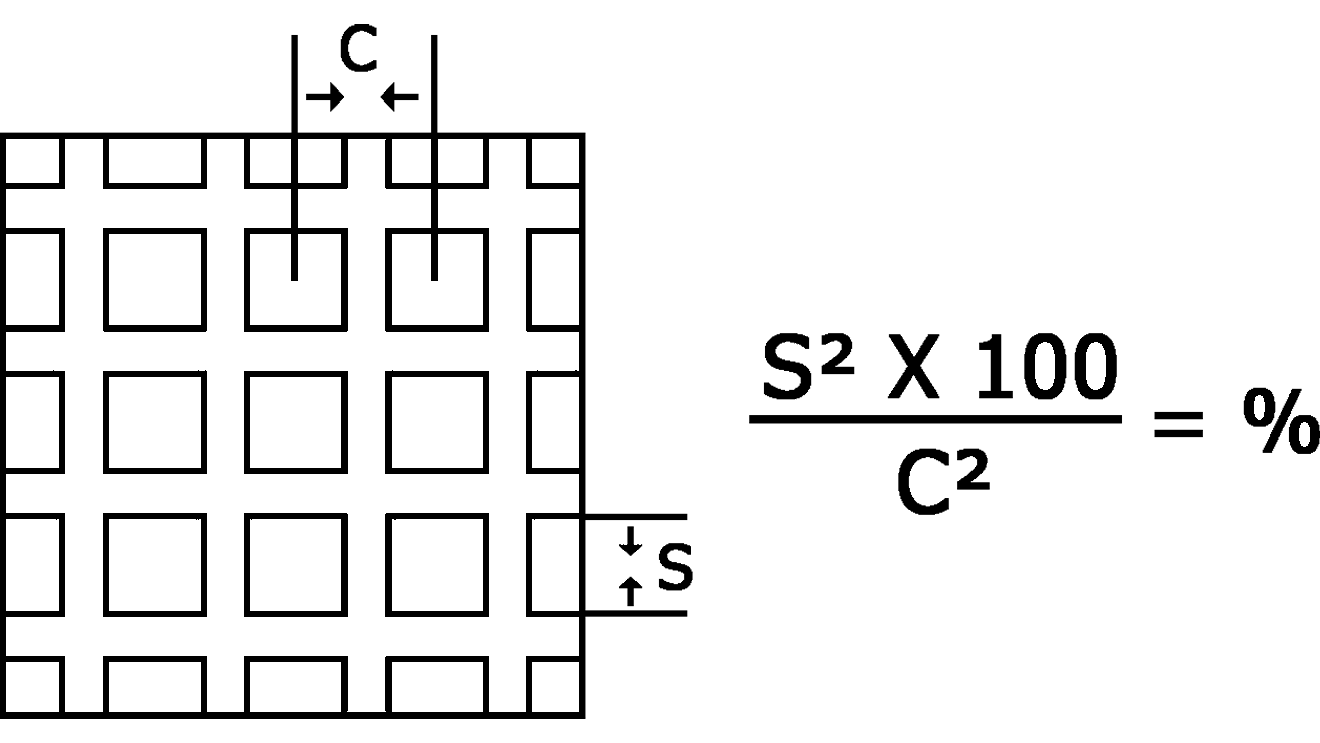

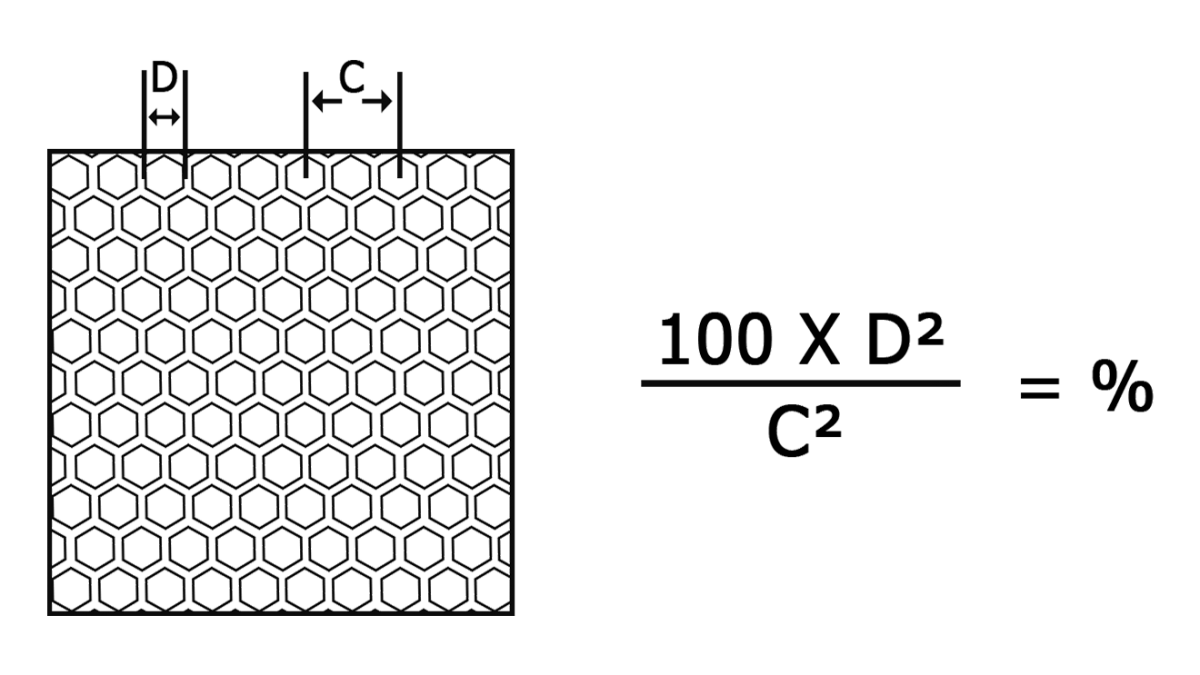

- Open Percent Formulas

Perforation Material

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Galvanized Steel Perforated Metal

- Steel Perforated Metal

- Brass Perforated Metal

- Titanium perforated Metal

Perforated Metal Applications

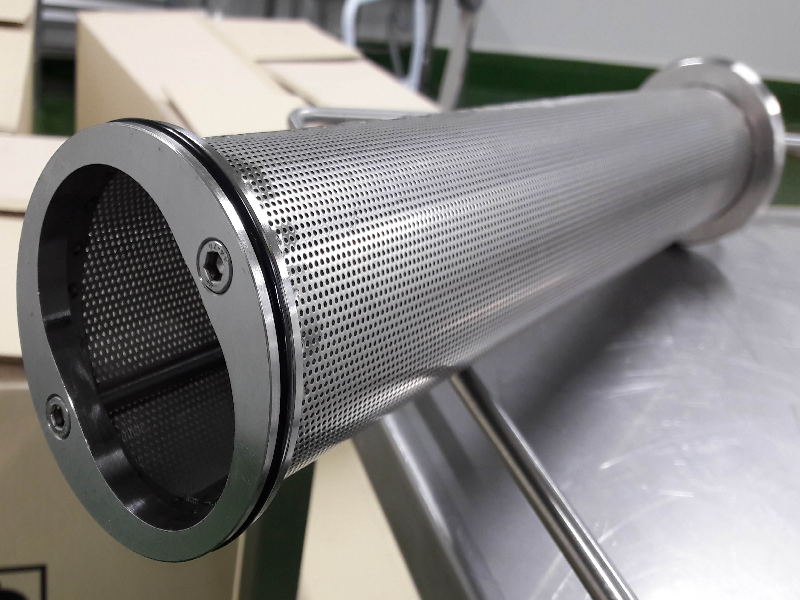

- Filters And Strainers

- Perforated Screen Plates

- Protective Cover For Equipment

- Anti-Skid Perforated Sheet

- Agricultural Equipment

- Pharmaceutical Component Parts

- Gutter Guard Mesh

- Balustrade Infill Panels

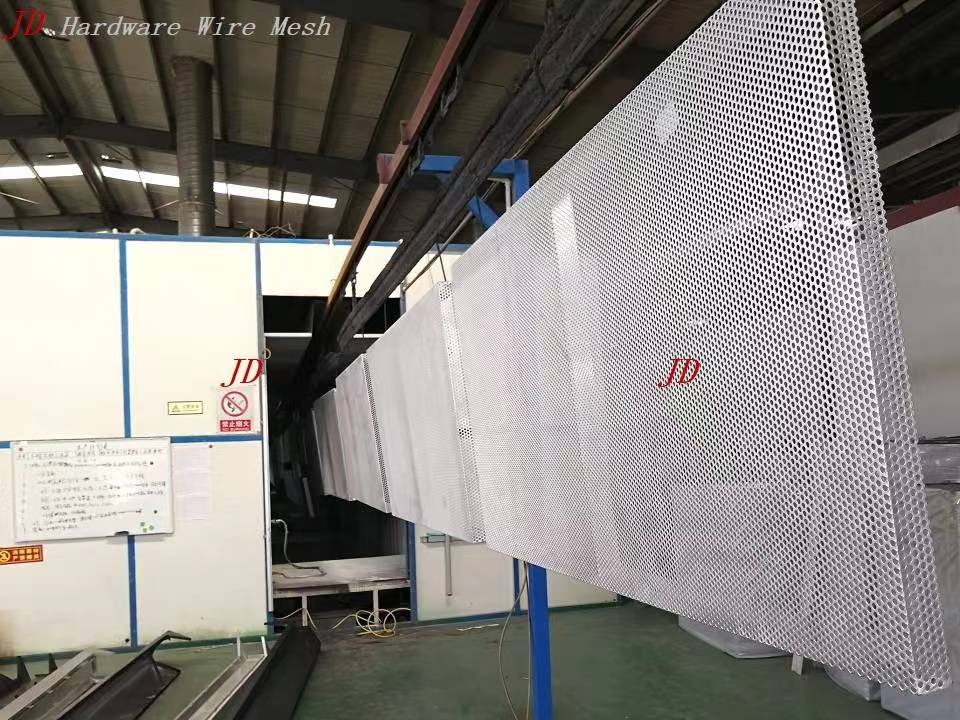

- Perforated wall panels

- Perforated Metal Ceilings

- Perforated Metal Facade

- Aluminum Expanded Facade Panel

Contact Us

Agricultural Equipment

Our diverse and wide range of products for different applications in the agricultural and food processing industry include: Milling screens, Cleaning screens, Drying mesh and animal feed milling consumables for agricultural equipment.

JD Hardware Wire Mesh tooling range and capabilities means that we can offer a wide range of perforation sizes, hole shapes and patterns so that you can achieve efficient cleaning using screens that remove unwanted materials from crops, from corn, seeds, grain, rice and maize. Pre cleaning reduces the time needed for milling improving your output and quality process. Grain cleaning allows for the removal of chaff, weeds, seeds, soil and other unwanted materials.

Grain Drying:

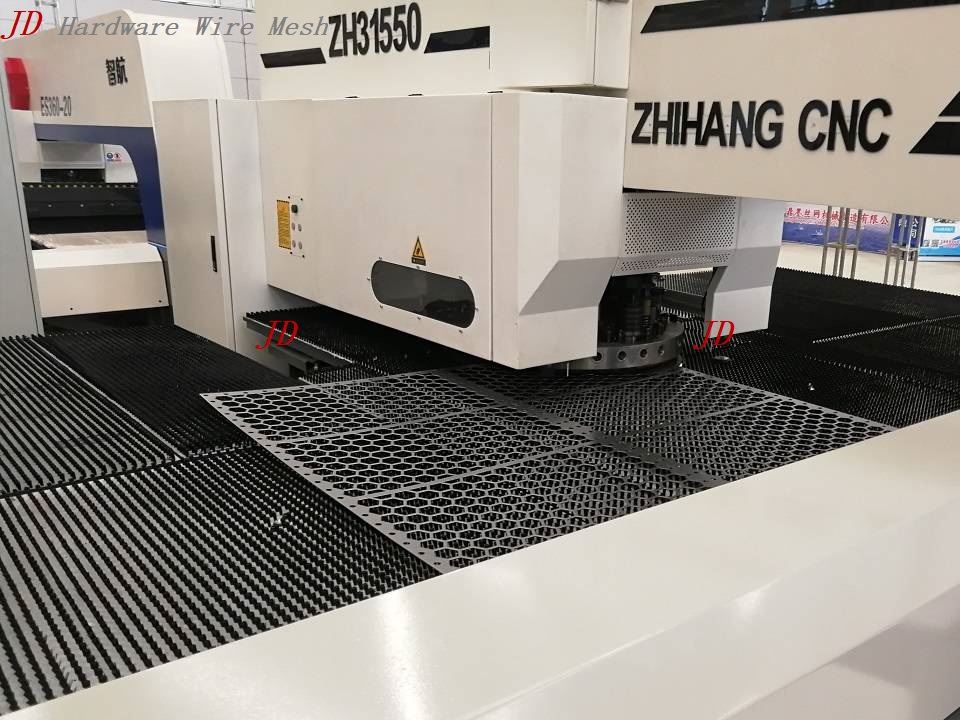

At JD Hardware Wire Mesh our screens our manufactured using the highest quality materials. It is important to use the right combination of perforation sizes and shape in order to achieve optimal airflow and strength. All of our screens are manufactured to a high standard and allow for effective processing through our design processes of working closely with our customers. We understand that the design of the drying screen can effect airflow which in turn effects the drying rate. Which is why our tooling and machinery enable us to create tailored design to meet customer specifications. So whether its perforated screens for silo drying or metal screens for floor drying, separation or grading screens we have the range and capabilities to ensure the best possible screens for every crop type to ensure optimum crop yields.

Technical Details:

Hole size: 1 mm up to 100mm (other hole sizes also available but not recommended)

Thickness: Popular thickness: 0.75mm up to 12mm (other thicknesses also available upon request)

Sheet sizes: Standard sheet sizes – 2 x 1m, 1.22 x 2.44m, 2.5 x 1.25m and 3 x 1.5m, special sizes also available to order.

Percentage open area: 20% to 50% standard open area – Higher open areas available

Dinner on the Table

We are your perfect partner for food prep, supplying perforated metal components for:

Conveyor belts for making dry foods

Metal sheets for dehydration

Bread pans and baking products

Ovens with perforated metal screens around the sides

Metal colanders to rinse produce

Sterilization racks

JD Hardware Wire Mesh provides essential parts to enable food producers to feed the world, supplying precision-made perforated metal components for digging, planting, harvesting, milling, and food preparation — helping at each stage of the agricultural process.