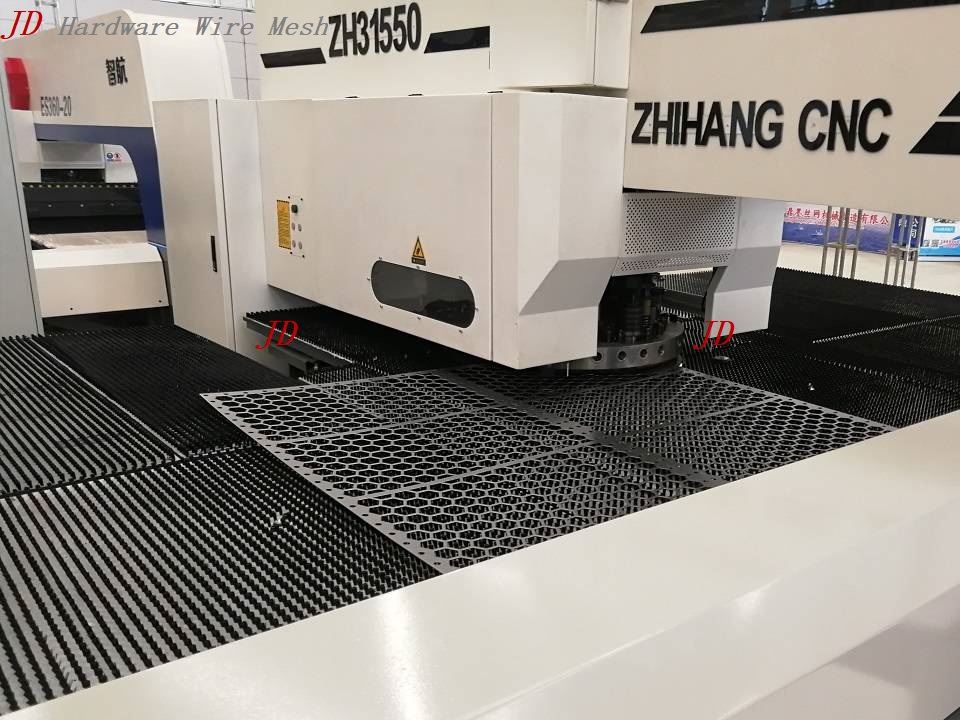

High Speed Gantry Punch Machine

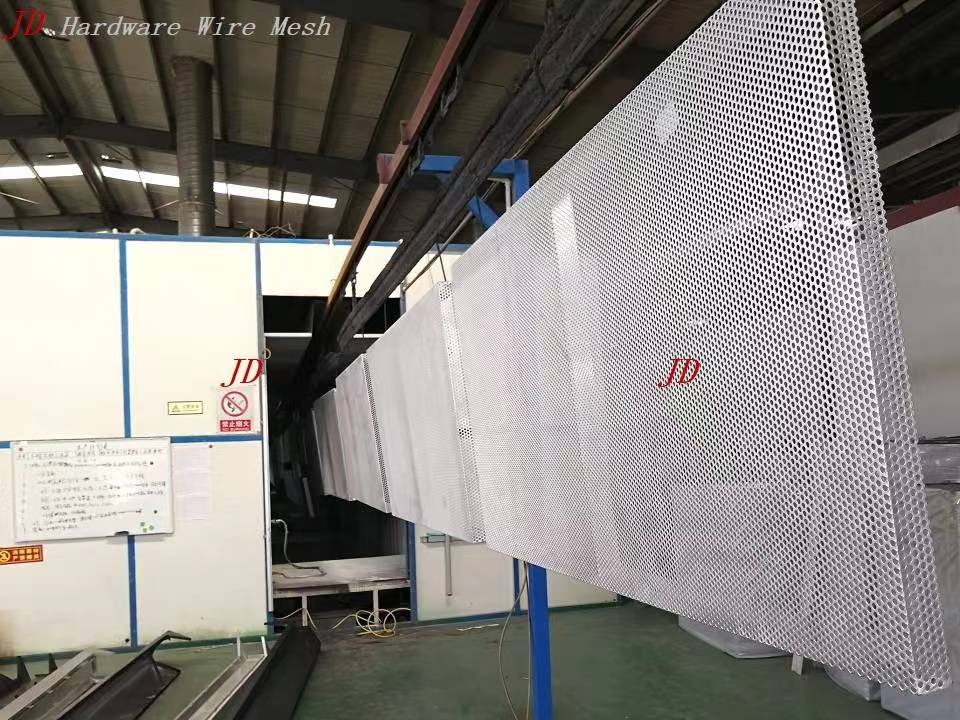

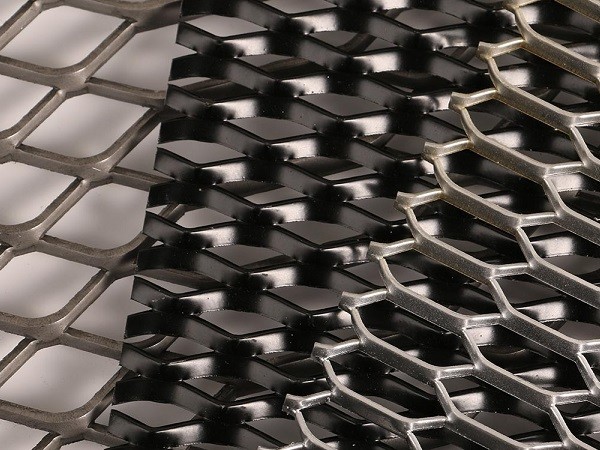

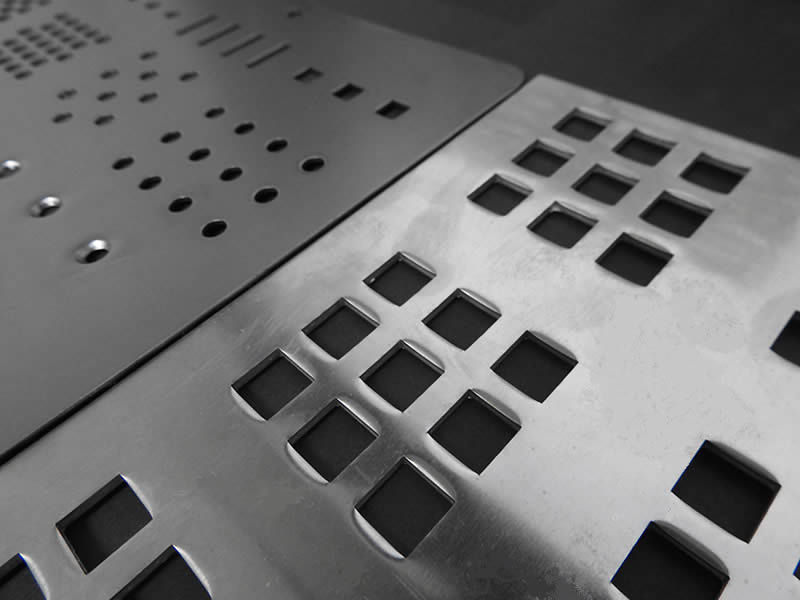

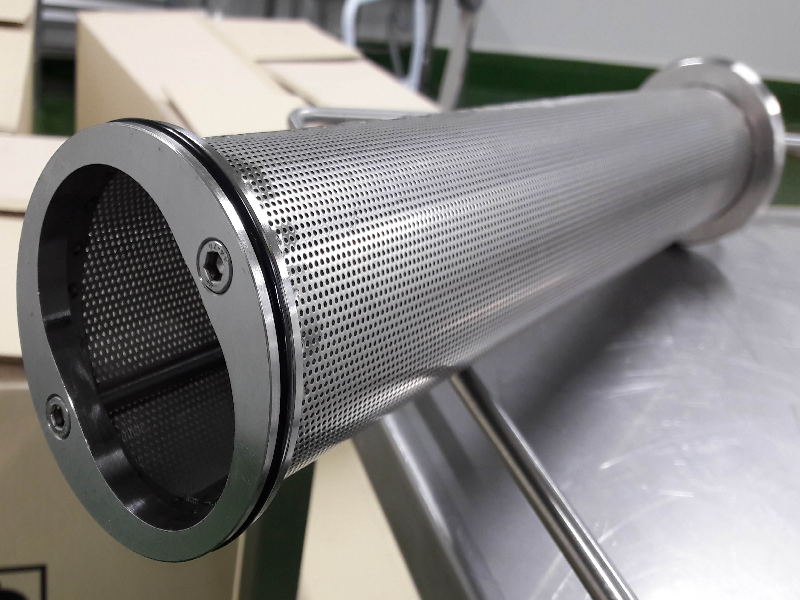

High-speed gantry punch machine is made of integrated special cast iron alloy, which can meet the needs of any automatic production. It is suitable for processing large number of round holes with fixed plate width. It is often used for perforated rolling plate and corrugated perforated metal panels.

Advantages:

Advantages:

Fast production and processing efficiency can generate huge economic benefits.

Low processing labor intensity.

High machining accuracy.

Disadvantages:

Machines cost expensive.

Suitable for thin plate thickness.

Perforated Metal Plate Specification:

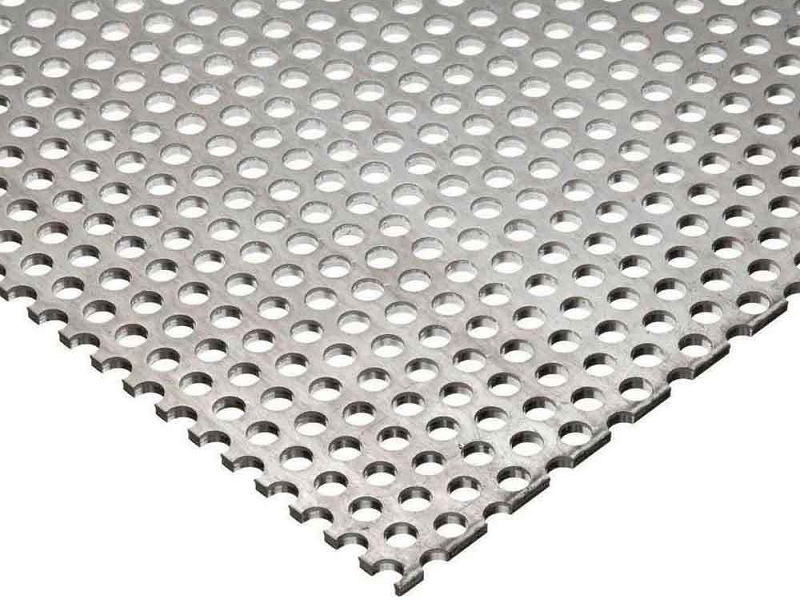

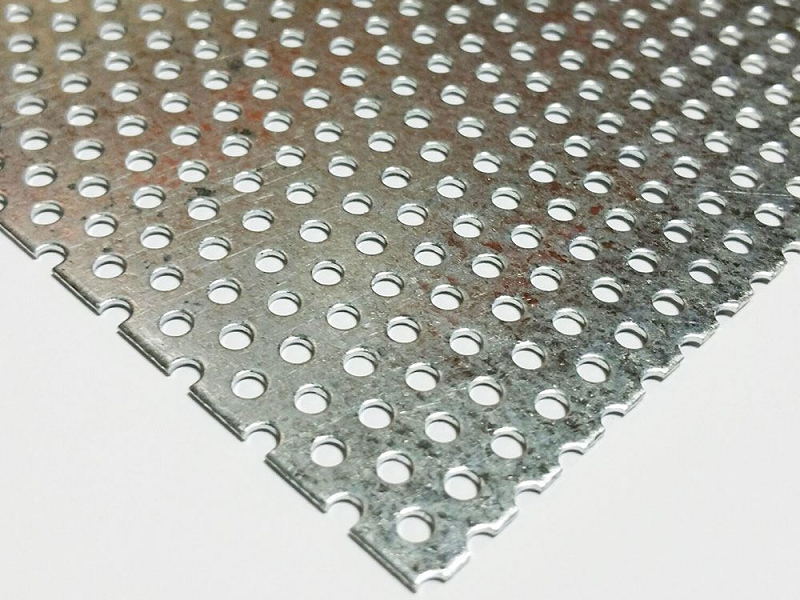

Material: stainless steel, aluminum, aluminum alloy, galvanized steel.

Thickness: 0.5mm – 2mm.

Width: 0.1m – 1.5m.

Length: Length no limited.

Standard size: 1.0m × 2.0m, 1.22m × 2.44m, 1.25m × 2.5m, 1.5m × 3.0m.

Hole diameter: 0.8mm–20 mm.

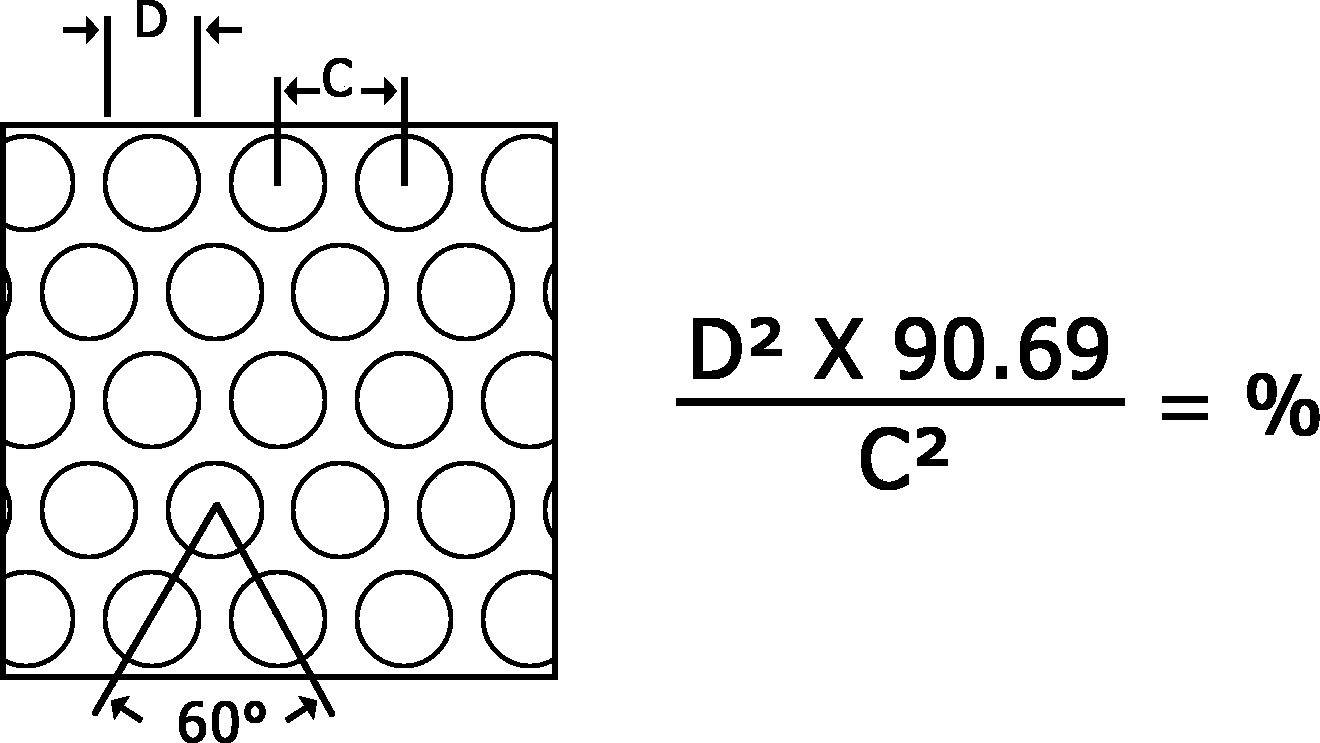

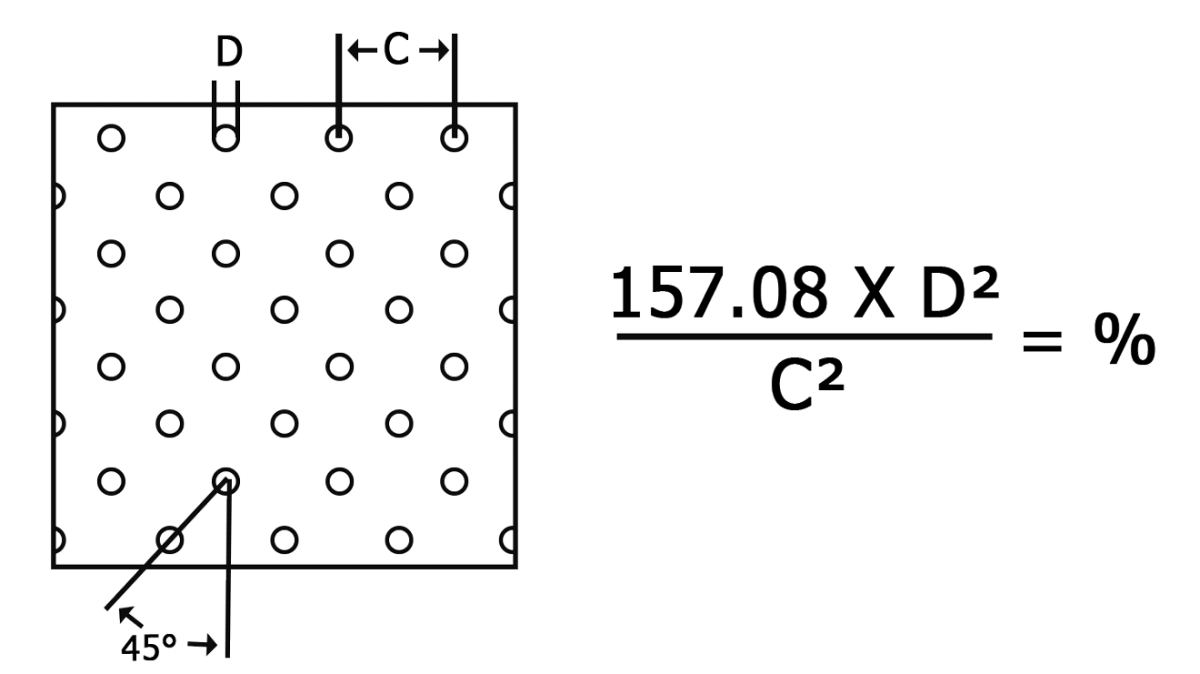

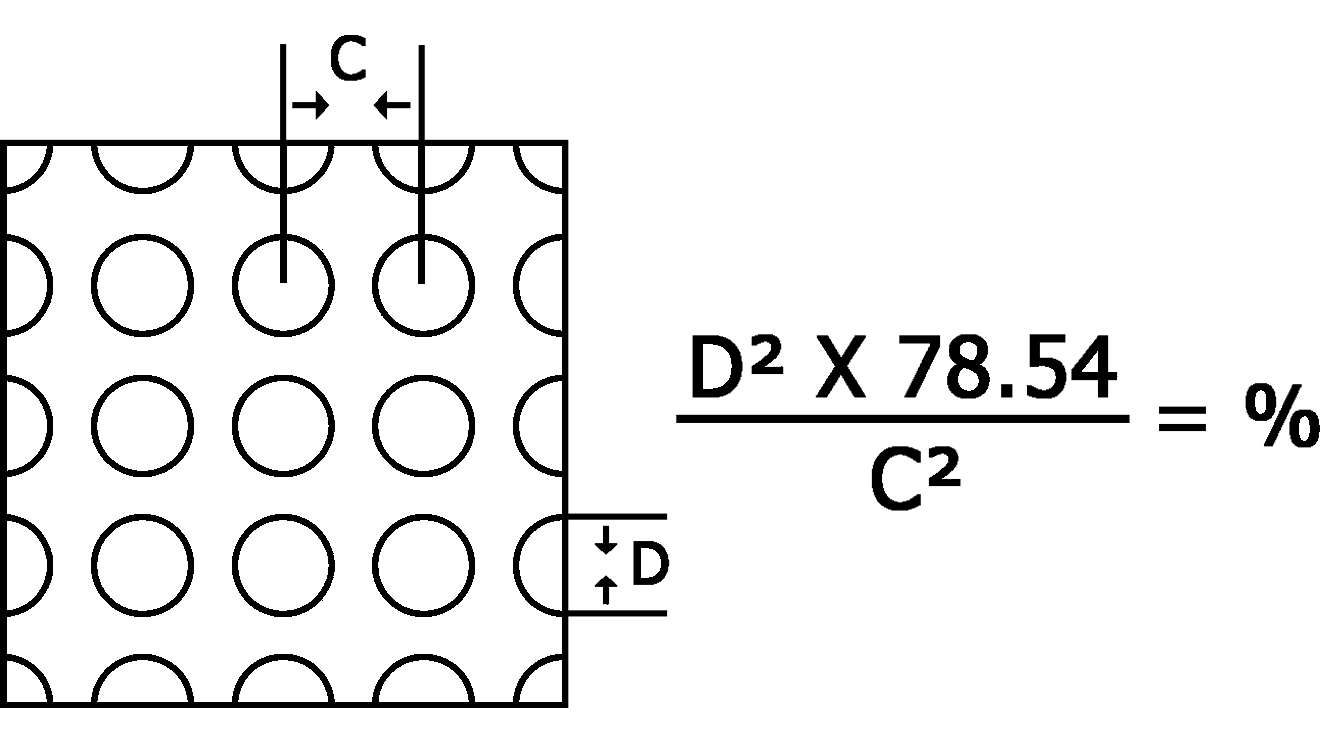

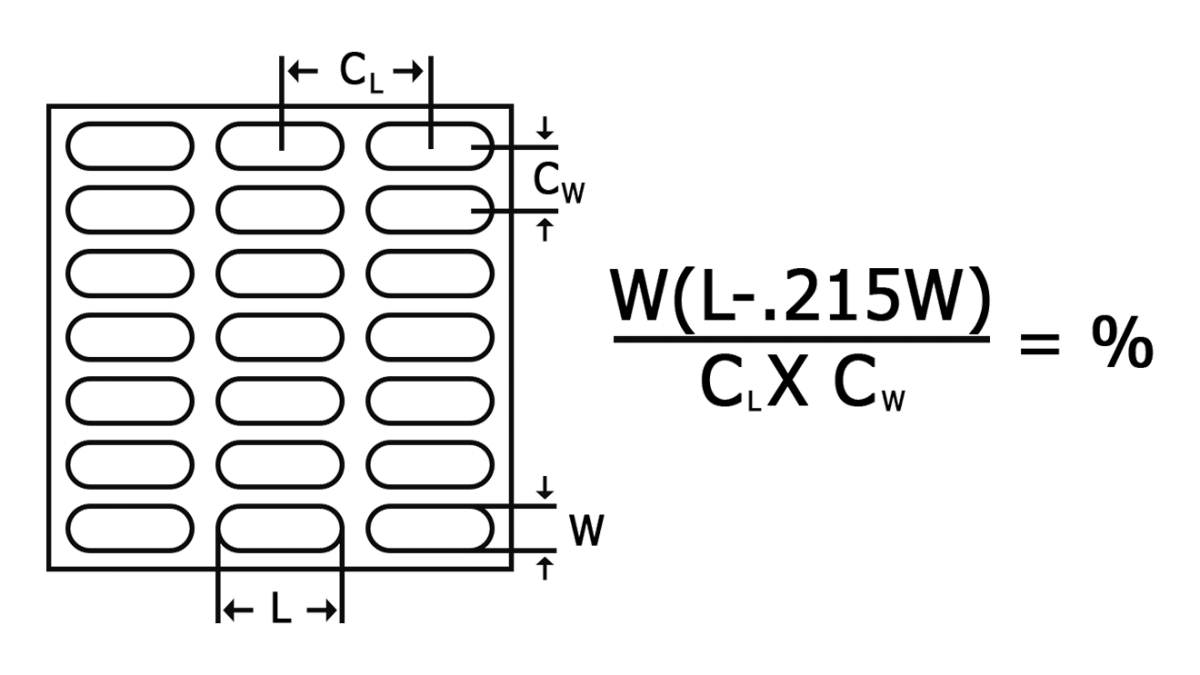

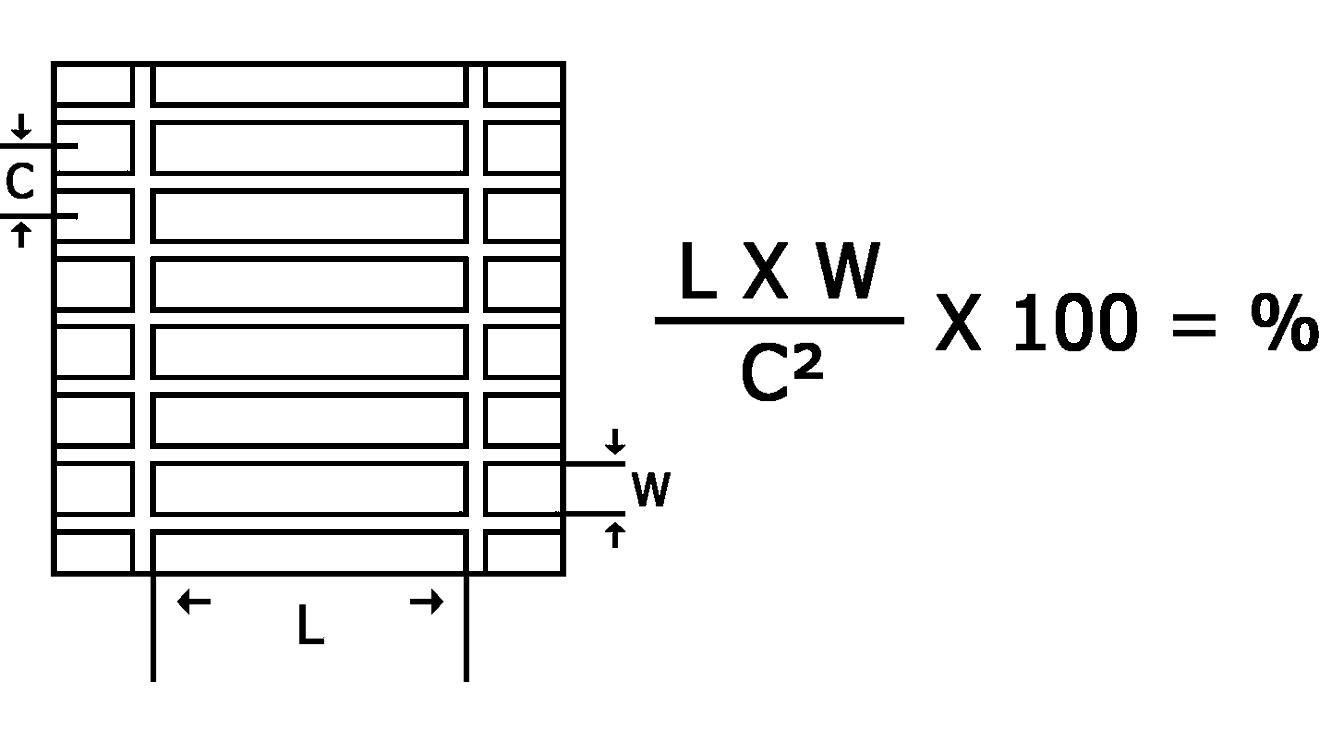

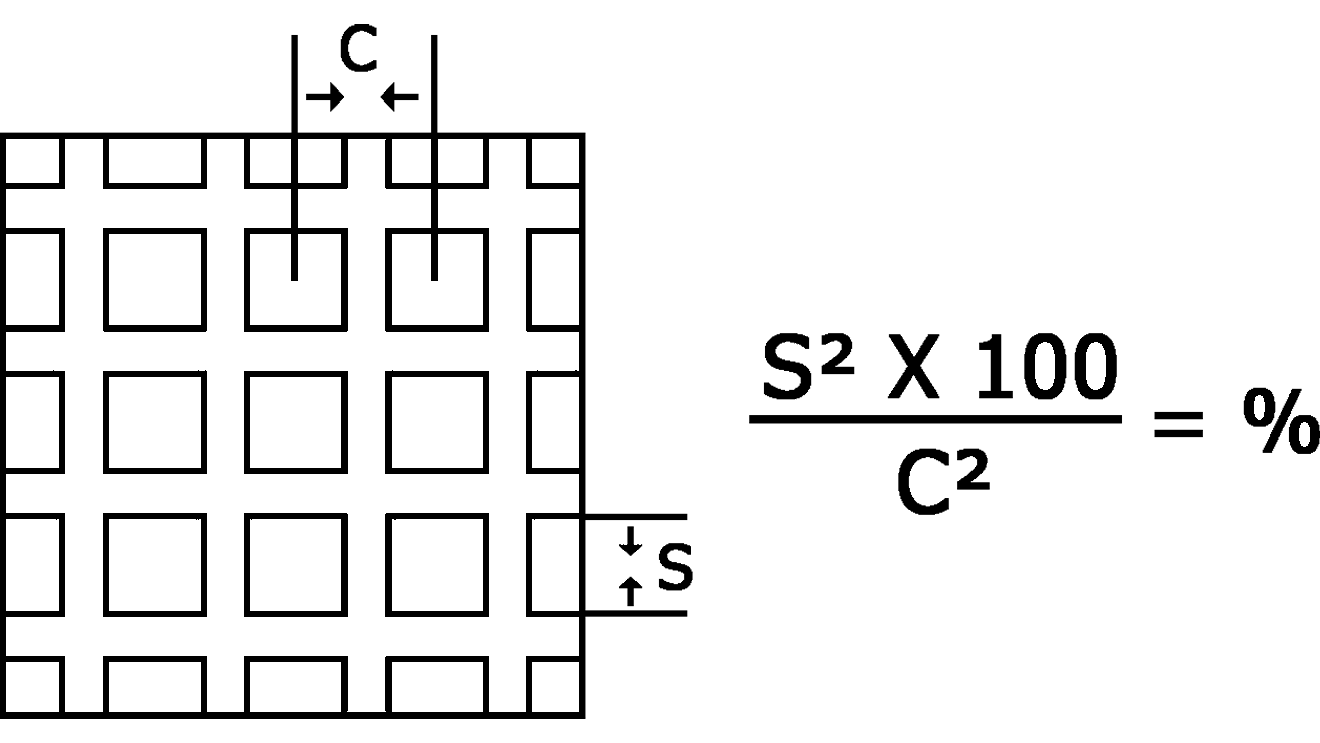

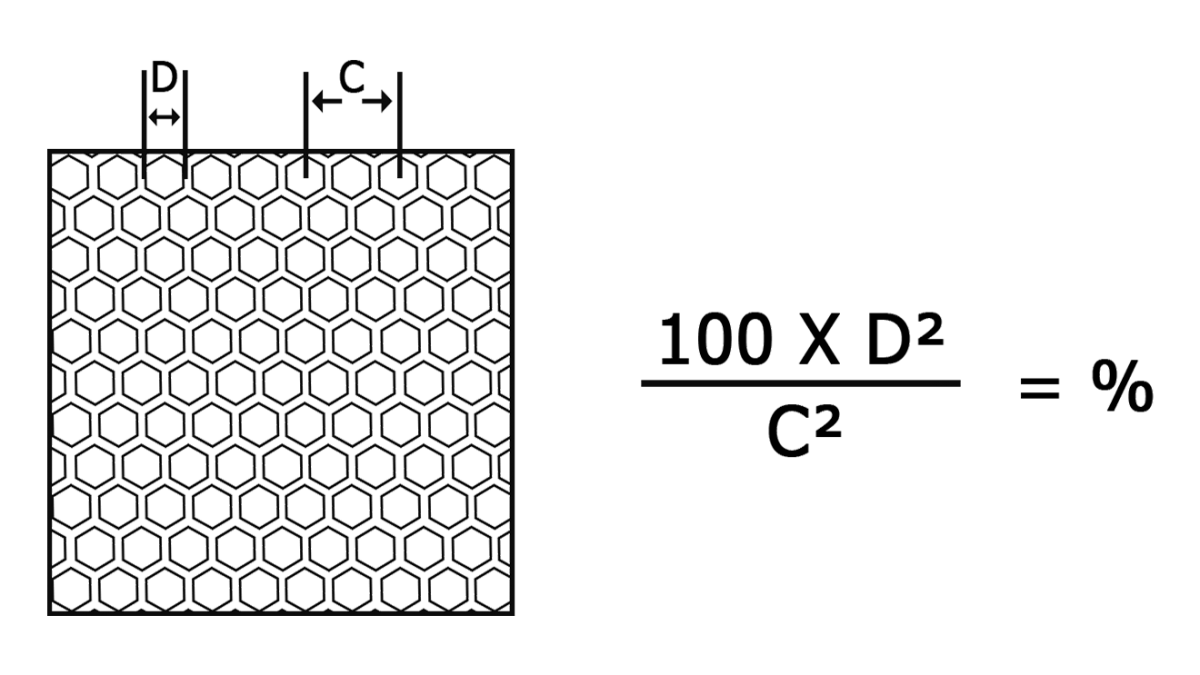

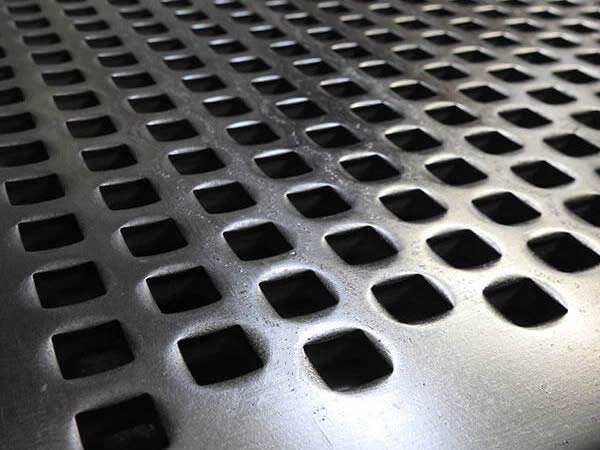

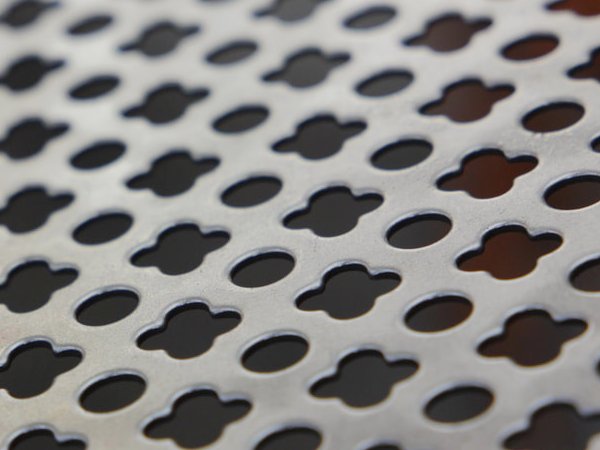

Hole arrangement mode: straight, staggered.

Staggered center: 0.125–1.875 mm.

Mesh opening area: 15% – 60%.

Pattern design: no available.

Fast production and processing efficiency can generate huge economic benefits.

Low processing labor intensity.

High machining accuracy.

Disadvantages:

Machines cost expensive.

Suitable for thin plate thickness.

Perforated Metal Plate Specification:

Material: stainless steel, aluminum, aluminum alloy, galvanized steel.

Thickness: 0.5mm – 2mm.

Width: 0.1m – 1.5m.

Length: Length no limited.

Standard size: 1.0m × 2.0m, 1.22m × 2.44m, 1.25m × 2.5m, 1.5m × 3.0m.

Hole diameter: 0.8mm–20 mm.

Hole arrangement mode: straight, staggered.

Staggered center: 0.125–1.875 mm.

Mesh opening area: 15% – 60%.

Pattern design: no available.