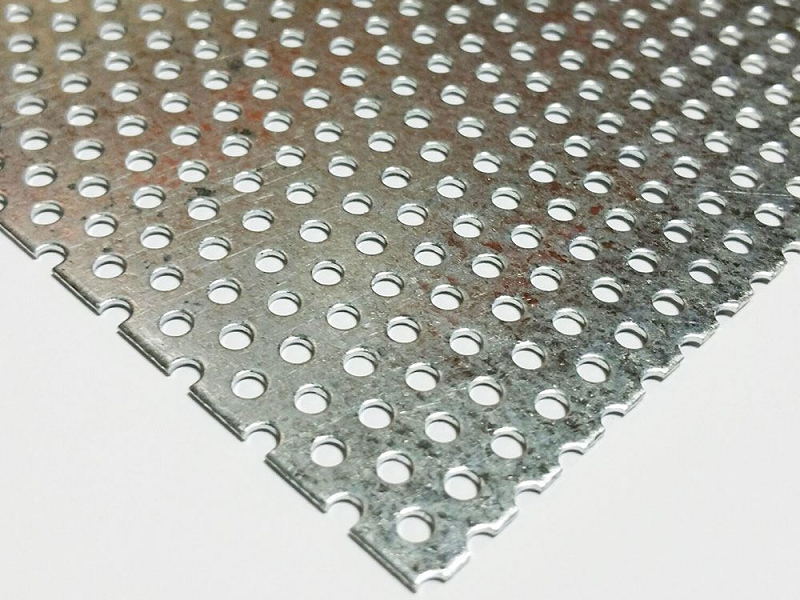

Hole Pattern

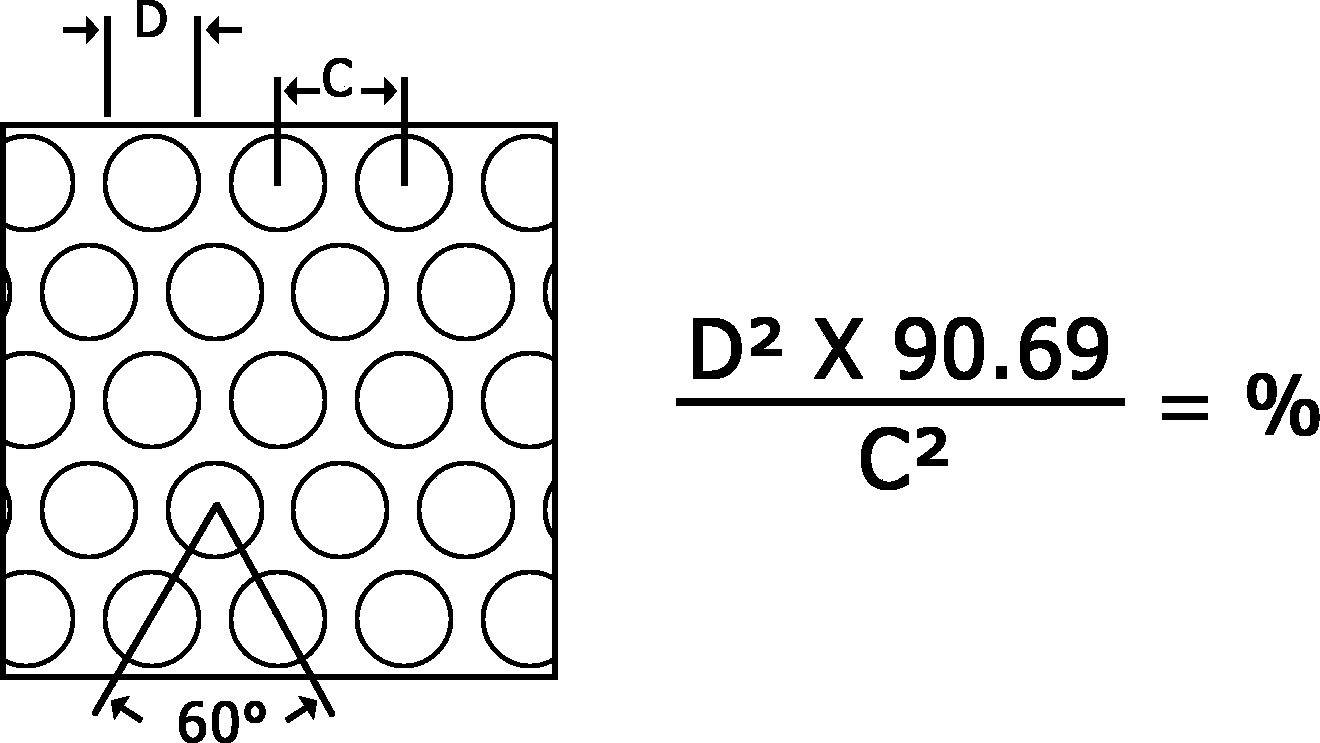

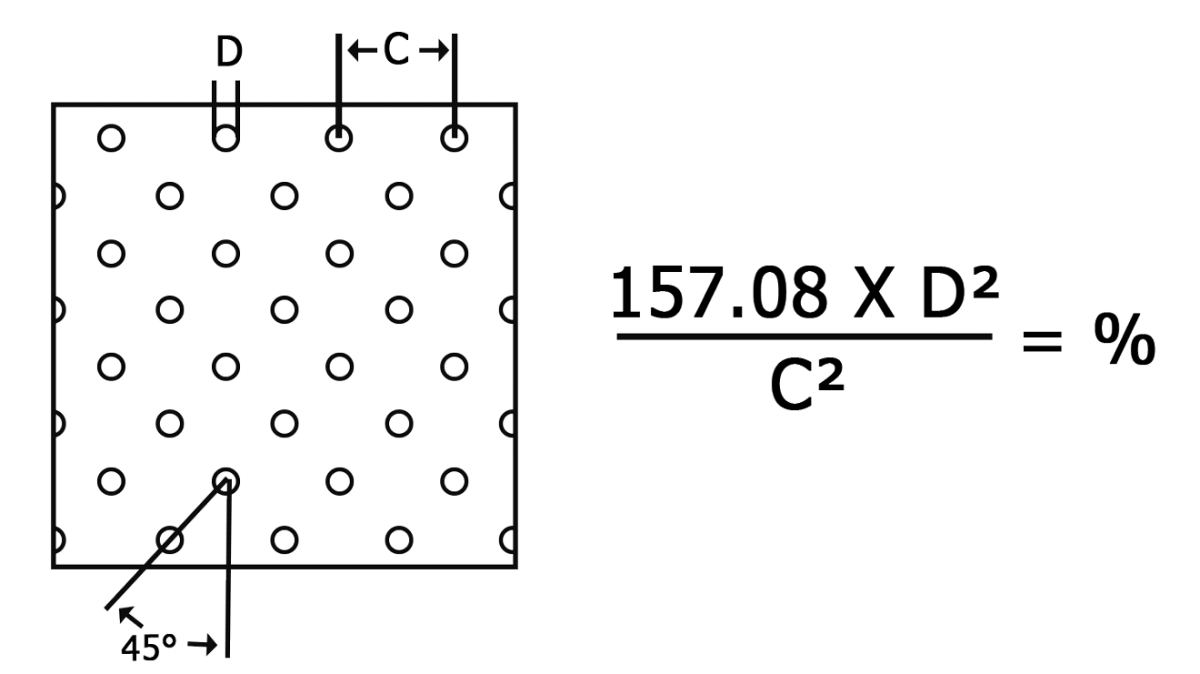

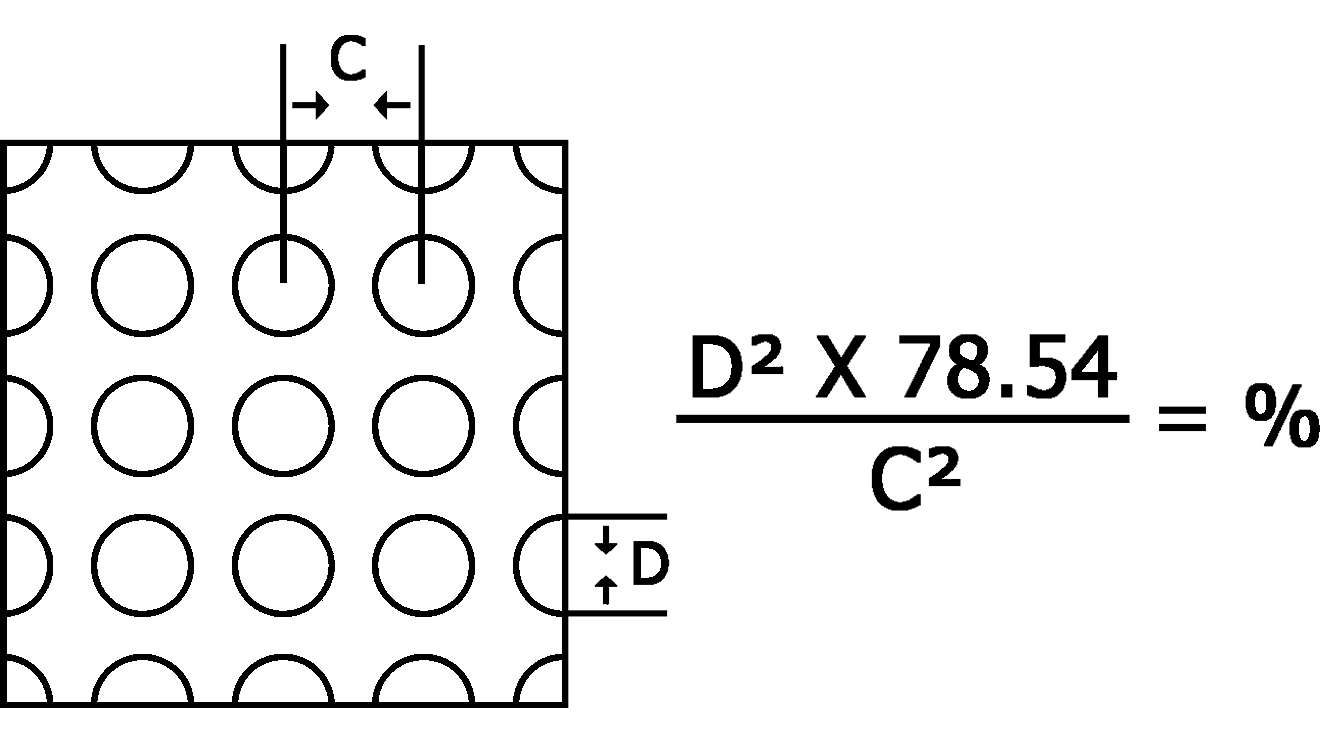

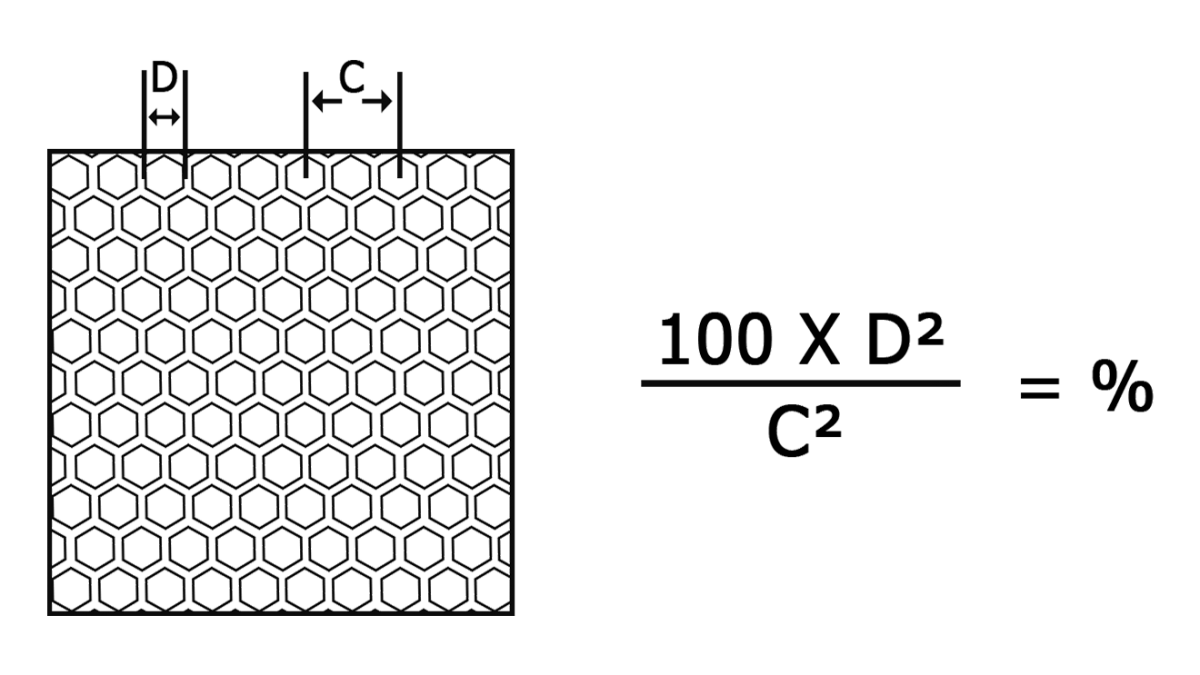

- Round Hole Perforated Metal

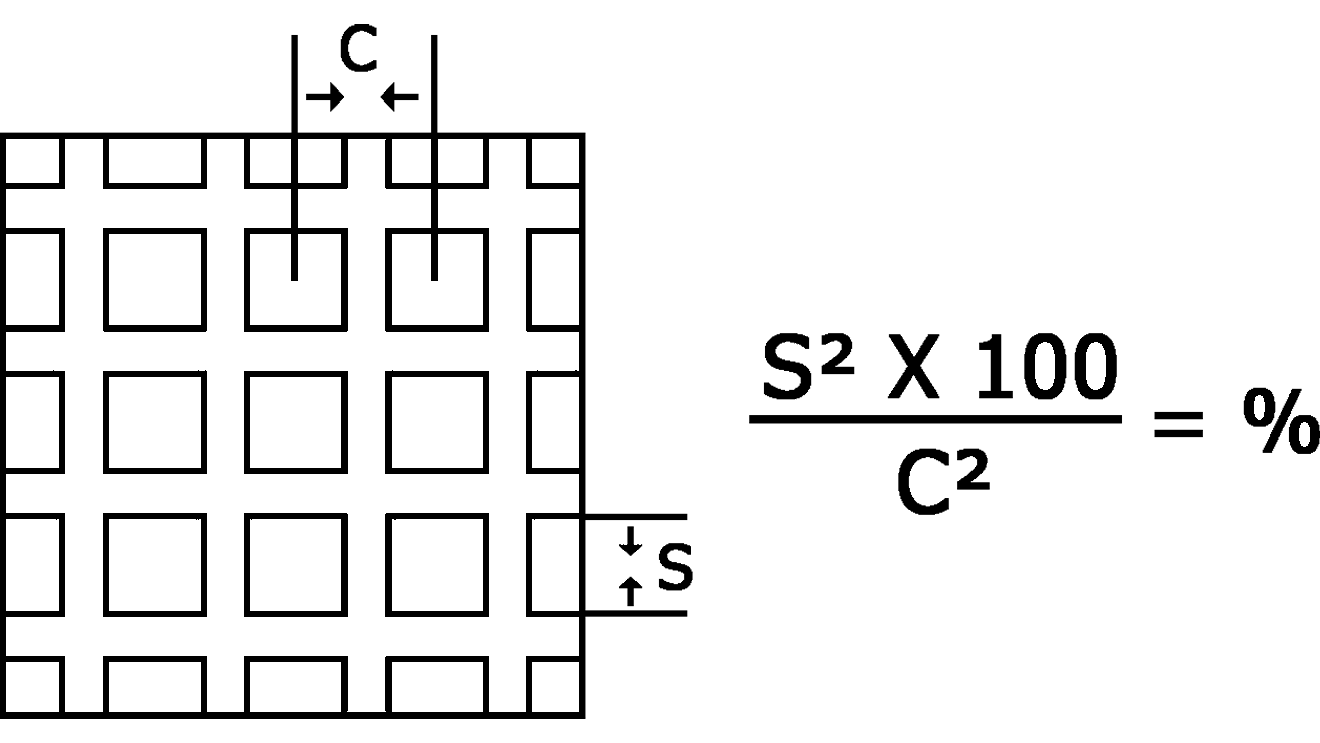

- Square Hole Perforated Metal

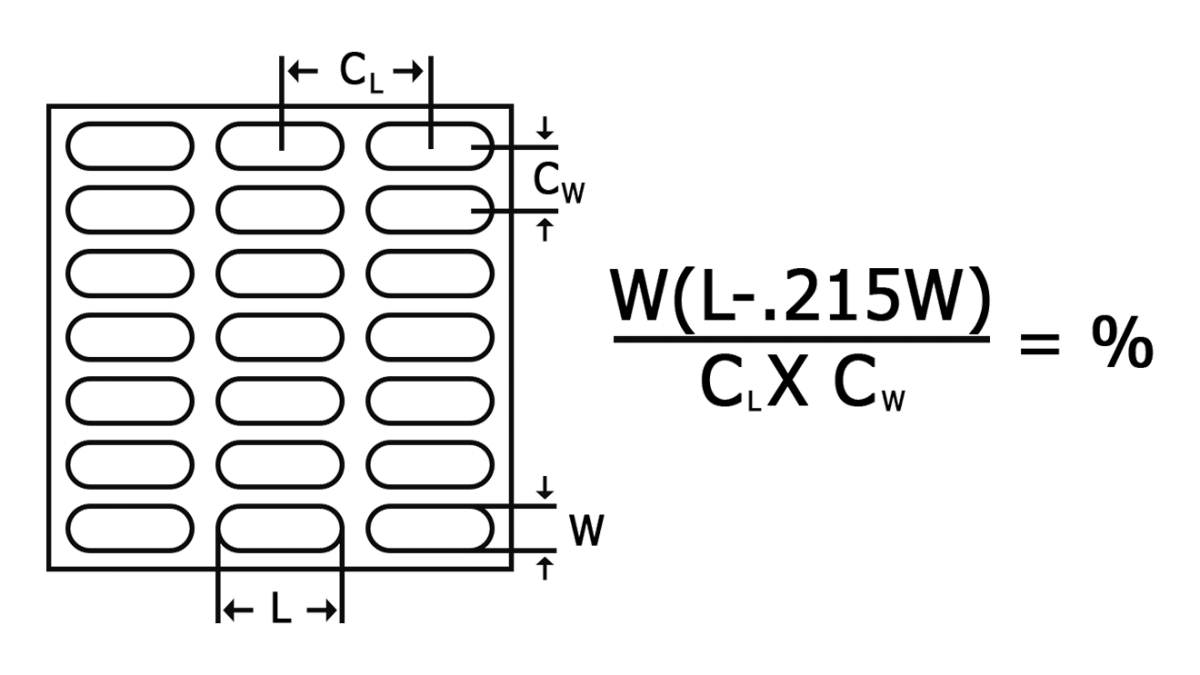

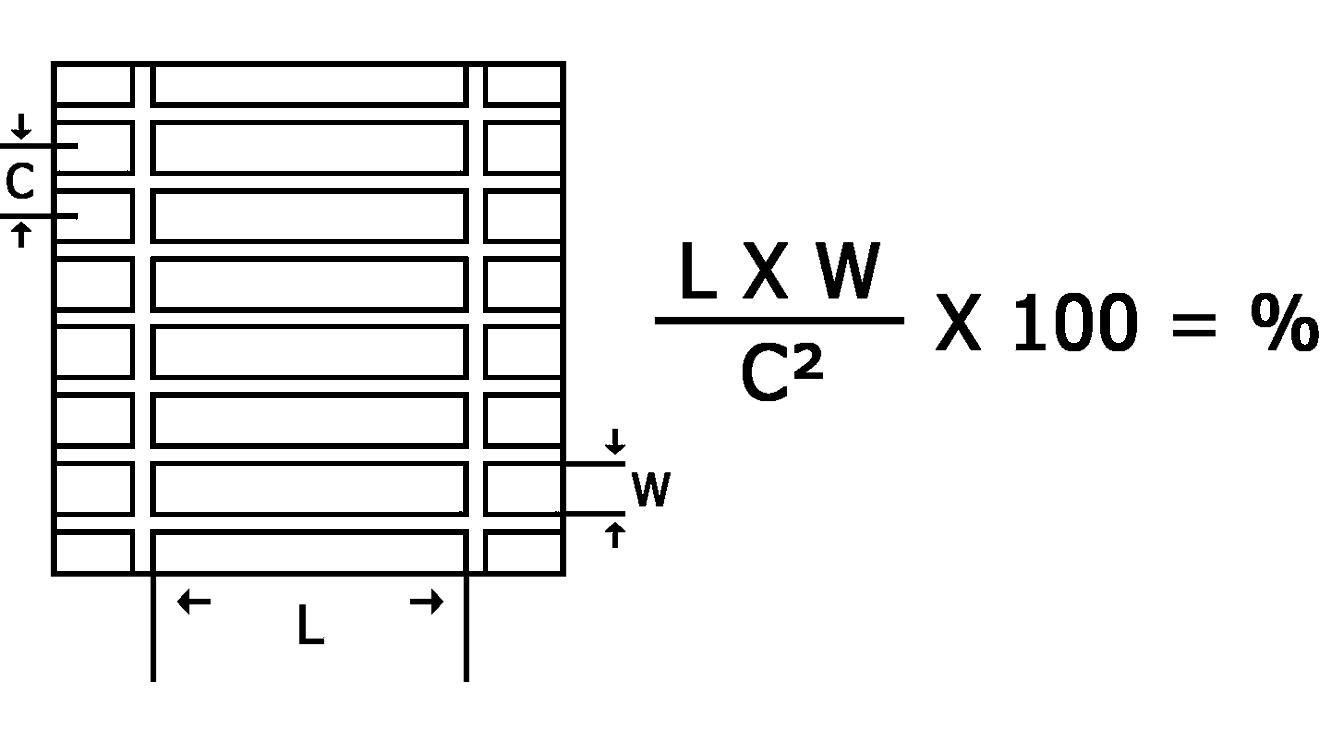

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Open Percent Formulas

Perforation Material

- 904L Stainless Steel

- 430 Stainless Steel Wire Cloth & Grating

- 410 Stainless Steel

- 347 Stainless Steel

- 321 Stainless Steel

- 316/316L Stainless Steel

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Steel Perforated Metal

- Galvanized Steel Perforated Metal

- Brass Perforated Metal

Perforated Metal Applications

- Filters

- Perforated Screen Plates

- Protective Cover For Rquipment

- Noise Control

- Perforated Metal Ceilings

- Fill Panel Applications

- Aluminum Exterior Building Facades

- Anti-Skid Perforated Sheet

304/304L Stainless Steel

Type 304 stainless steel serves a wide range of applications. It withstands ordinary rusting in architecture, it is resistant to food processing environments, it resists organic chemicals, dyestuffs, and a wide variety of inorganic chemicals.

Type 304L: A low carbon version of type 304 stainless. 304L is used almost interchangeably with 304 but is preferred for welding operations. It offers a good combination of strength, corrosion resistance and is easily fabricated.

Applications: The list for 304 stainless steel is endless. Almost every conceivable industry uses some of this material in some way. Everything from stovetops to ball point pen barrels to flatware to fasteners has been fabricated from this alloy.

Machinability: Slow speeds and heavy feeds will minimize this alloys tendency to work harden. Due to long stringy chips, the use of chip breakers is advisable. Many companies now offer premium machinability grades, such as CarTech with their Project 70 and 7000 series.

Welding: All fusion and resistance processes have been successfully employed in welding 304 stainless. AWS E/ER308 or 312 filler metal is recommended. Its low carbon, means that the is less carbide precipitation at the weld boundaries resulting in stronger welds.

304/304L Chemistry

| Carbon | 0.08 max / 0.03 max |

| Chromium | 18 - 20 |

| Iron | Balance |

| Manganese | 2 max |

| Nickel | 8 - 12 |

| Phosphorous | 0.045 max |

| Silicon | 1 max |

| Sulphur | 0.03 max |

304/304L Physical Data

| Density (lb / cu. in.) | 0.29 |

| Specific Gravity | 7.9 |

| Specific Heat (Btu/lb/Deg F - [32-212 Deg F]) | 0.12 |

| Electrical Resistivity (microhm-cm (at 68 Deg F)) | 432 |

| Melting Point (Deg F) | 2650 |

| Modulus of Elasticity Tension | 28 |